旭化成化成开发创新

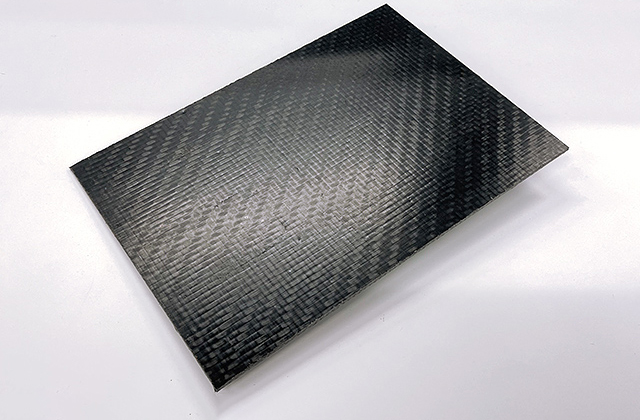

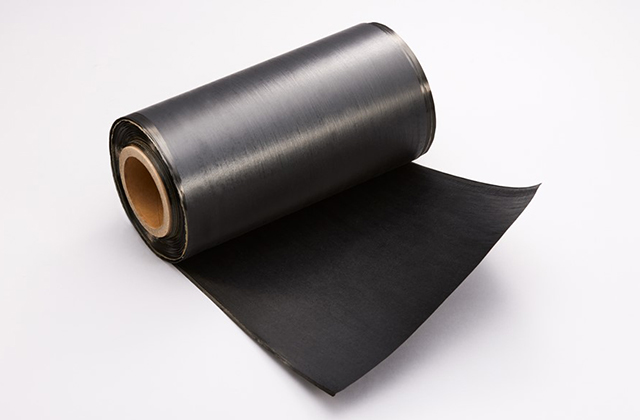

高性能工程塑料

并提供定制化解决方案

- 轻的

- 耐热性

阻燃 - 高强度 刚性

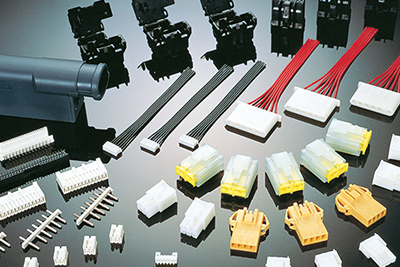

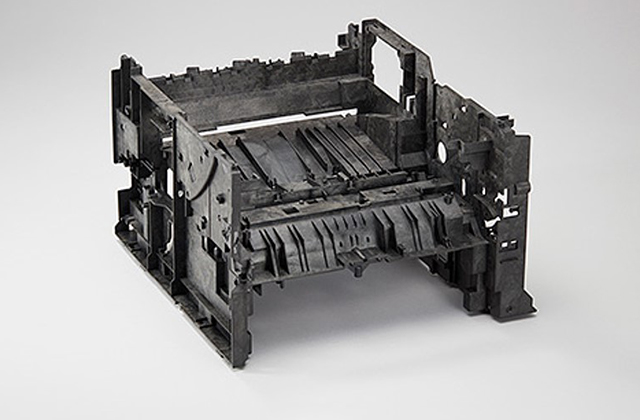

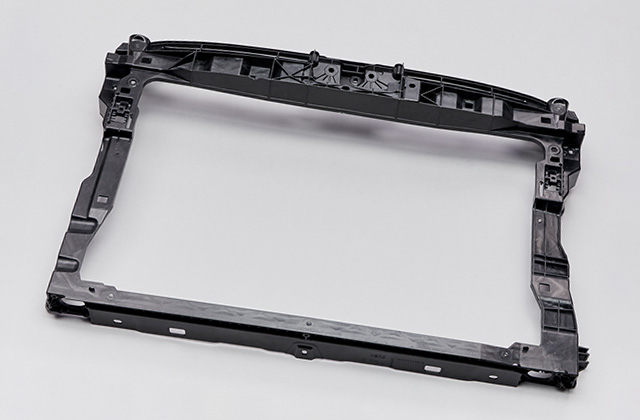

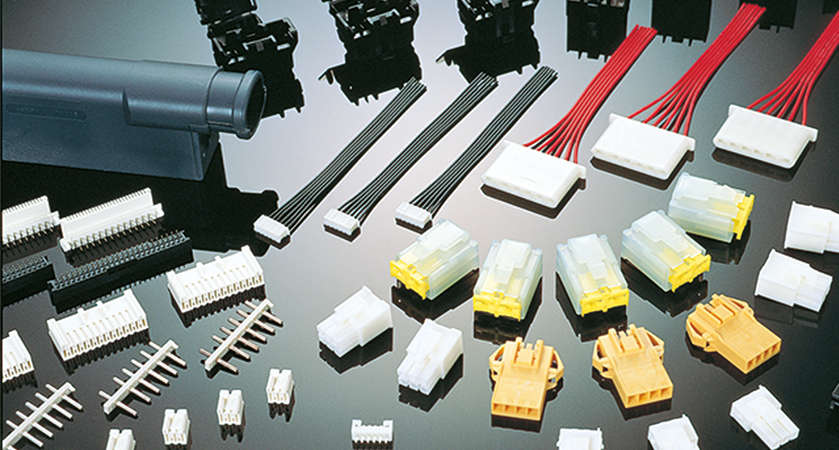

产品

介绍旭化成的工程塑料产品、其特征以及在各个领域的应用实例。

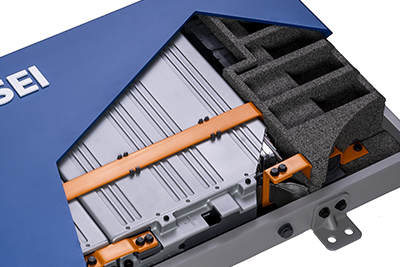

解决方案

以下是我们用于近年来流行的行业和领域的一些产品。

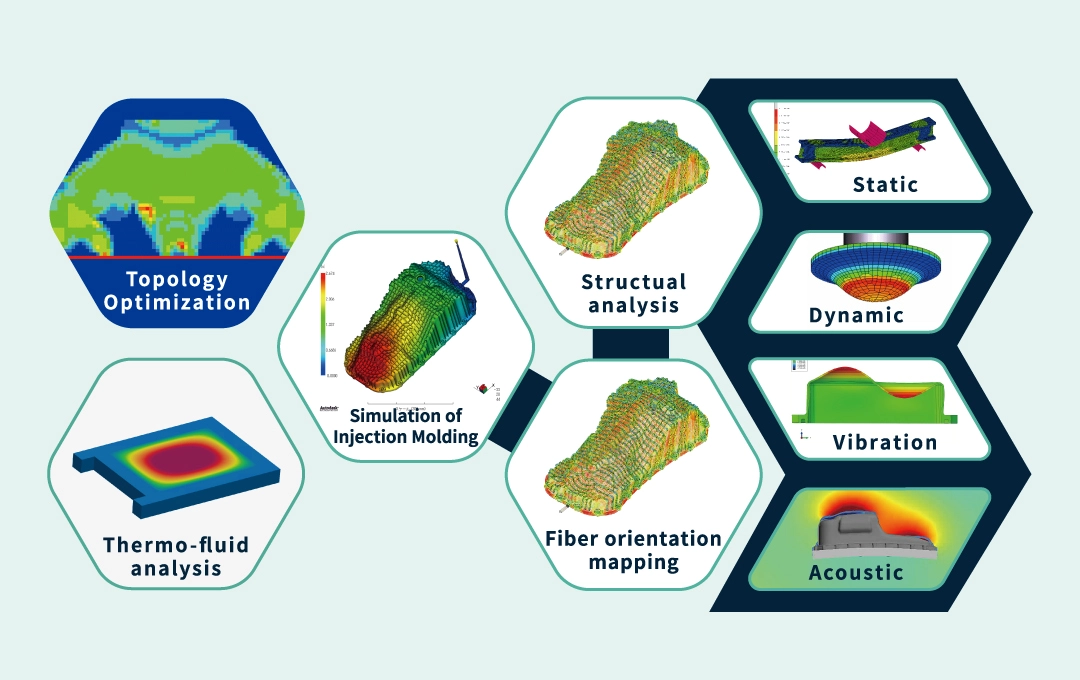

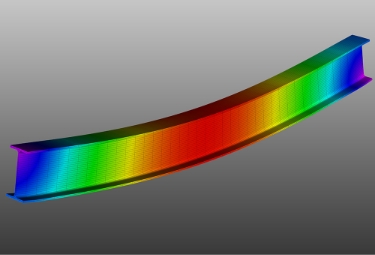

CAE 服务

引入 CAE 服务,利用我们在树脂方面的专业知识来帮助优化零件设计和解决问题。

工程塑料基础

我们将介绍工程塑料材料的特性、使用领域、加工方法等。

消息

- 旭化成的工程塑料如何帮助实现碳中和。

- 旭化成集团正在采取政策加速实现碳中和的进程。

我们介绍通过工程塑料实现循环经济的方法。 -

点击此处了解详情