- TOP

- 技術サポート

- Examples of CAE results

- Accuracy validation of impact analysis:Oil pan

Impact analysis

Accuracy validation of impact analysis:Oil pan

Summary

- We validated the performance of a plastic oil pan whose weight was reduced by 60% from the original metal part through topology optimization.

-

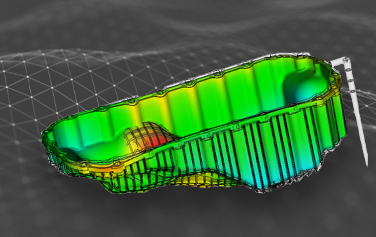

- Simulation of a metal ball impacting a plastic oil pan were performed and were validated with an actual test using a high-speed camera. Both results compared well with a high degree of accuracy.

Introduction

Reducing vehicle weight is crucial in reducing CO2 emissions for it directly impacts fuel economy.

We evaluated the performance of a plastic

oil pan whose weight was reduced by 60% from the original metal part through topology optimization.

The oil pan, located at the bottom of the vehicle body, is prone to be damaged by stone chipping.

We have compared experimental and analytical results of stone chipping.

Reducing vehicle weight is crucial in reducing CO2 emissions for it directly impacts fuel economy.

We evaluated the performance of a plastic oil pan whose weight was reduced by 60% from the original metal part through topology optimization.

The oil pan, located at the bottom of the vehicle body, is prone to be damaged by stone chipping.

We have compared experimental and analytical results of stone chipping.

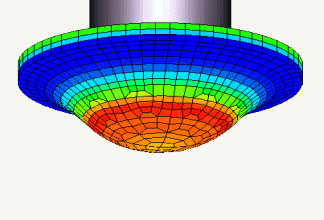

Fig.1 Oil pan

Purpose

Comparison between experimental and analytical results of stone chipping

Description

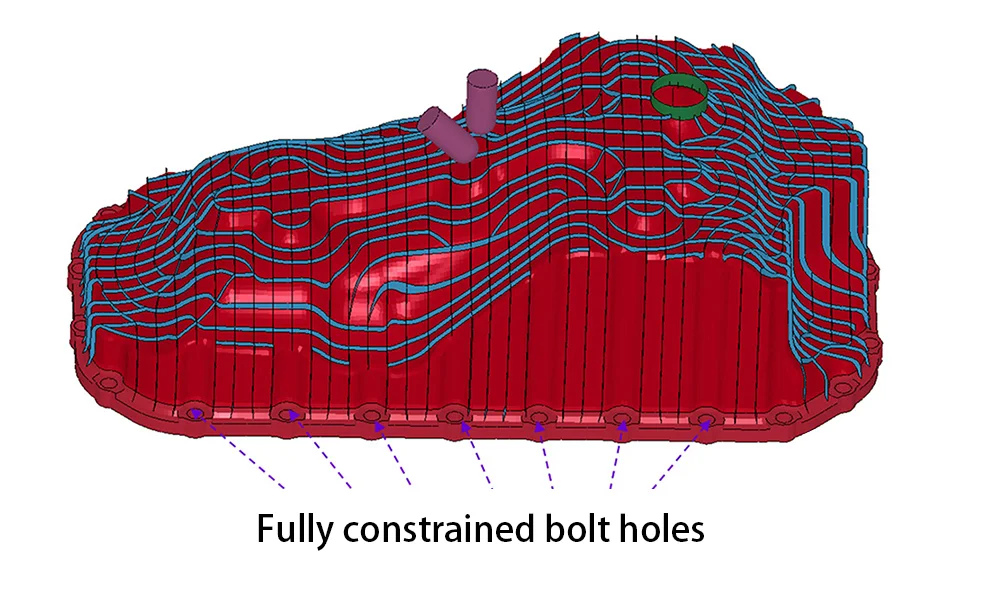

Impact analysis was performed with LS DYNA (Livermore Software Technology).

Chipping conditions were defined as a metal ball modeling a stone impacting a plastic oil pan at 80 km/h. The analysis results were compared with the actual test by using a high-speed camera.

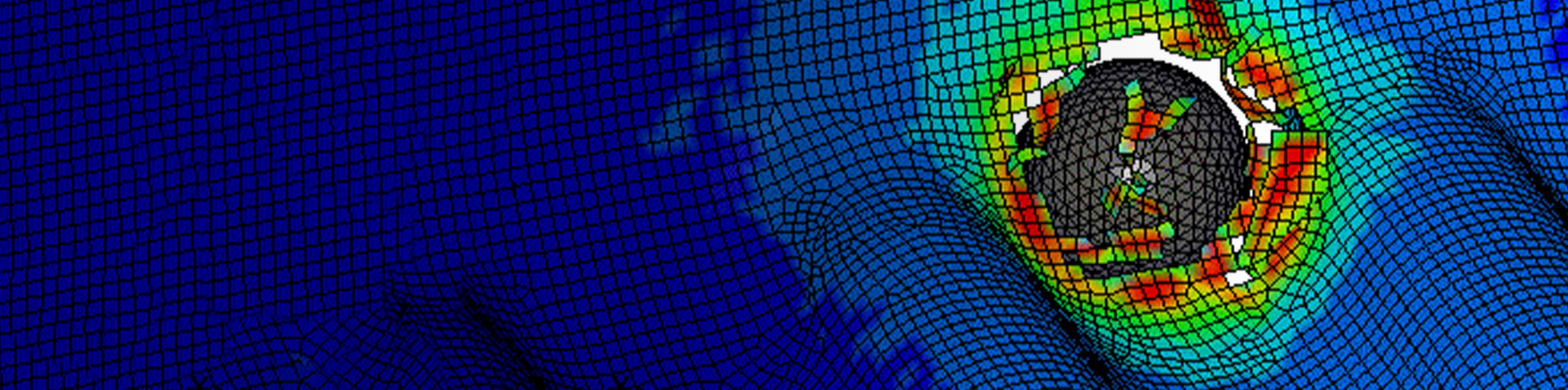

In impact analysis, it is important to set the correct boundary conditions on how the product is fixed.

Since the oil pan is bolted around the flange, the bolt holes were fully constrained in the analysis (Fig. 2).

Fig.2 Boundary condition

Results

Comparing the video in Fig. 3, the simulation and the actual experiment results are well matched.

Even when applied to actual products that are not test specimens, we were able to predict the results with a high degree of accuracy.

One of the reasons in achieveing the high accuracy of the prediction is that we have used a post-warping deformation model after injection molding analysis.

Fig.3 Comparison of the simulation and the actual experiment results

Material model

In this analysis, LEONATM 14G33 (PA66, GF33%) is used.

LEONATM 14G33 is a crystalline resin within thermoplastics.

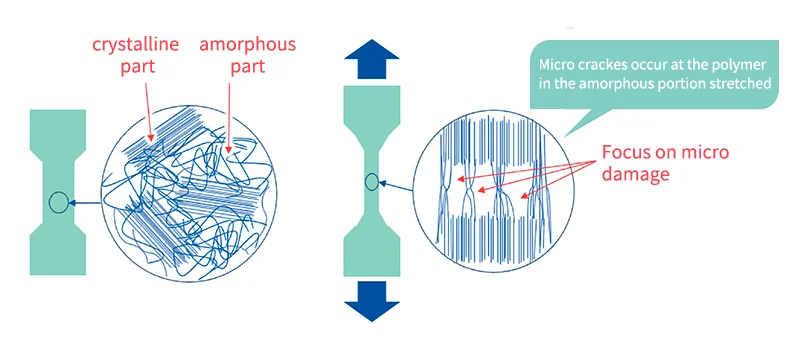

Crystalline resin forms spherulites by slow cooling from the molten state. The spherulites contain a mixture of lamellar crystalline portions with folded molecular chains of about 10 nm in size and amorphous portions with randomly coiled molecular chains.

During the deformation process of crystalline resins, crazing, a microscopic damage characteristic to resins, is observed as the deformation progresses.

At the time this analysis was conducted, there were few material models for impact analysis for resin materials. Some of simulations were even performed using material models for metal materials.

Therefore, we have developed a new original material model for crystalline polymer based on craze behaviour (Fig. 4).

If you are interested in the equations used in the material model, please refer to the literature.

Fig.4 Material model considering the craze effect

For more information about CAE, please contact us.

Inquiry