変性ポリフェニレンエーテル(変性PPE樹脂)とは

変性PPE樹脂の特徴や活用分野などをご紹介します。

1.変性ポリフェニレンエーテル(変性PPE樹脂)とは

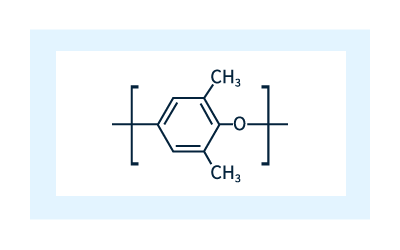

変性ポリフェニレンエーテル(変性PPE、m-PPE)とは、非晶性のエンジニアリングプラスチックであるポリフェニレンエーテル(PPE)樹脂と他樹脂を混合したポリマーアロイの総称です。PPE樹脂はガラス転移温度(Tg)が約210℃の非晶性の樹脂です。主鎖はベンゼン環をエーテル結合させているため耐加水分解性に優れています。また、吸水性が低く、比重は1.06と汎用エンジニアリングプラスチックの中で最も小さいです。線膨張係数も汎用エンジニアリングプラスチックの中で最小であり、寸法安定性に優れます。また電気特性も優れており、広い周波数範囲で誘電率・誘電正接を示します。その他には耐酸・アルカリ性にも優れる等の特徴があります。一方で、PPE樹脂単体では溶融時の粘度が高く成形加工性がしにくいこと、油等の芳香族炭化水素系溶剤に影響を受けやすいといった欠点があります。

なお、変性ポリフェニレンエーテルは、変性ポリフェニレンオキサイド(変性ポリフェニレンオキシド、変性PPO、m-PPO)と呼ばれることもありますが、PPOは登録商標であり、一般名はPPEになります。

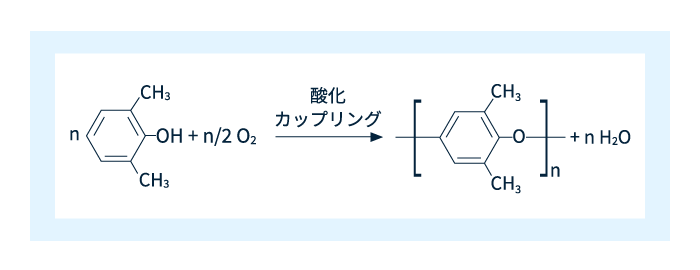

図1 ポリフェニレンエーテルの化学構造

図1 ポリフェニレンエーテルの化学構造

PPE樹脂単体で使用されることは稀であり、ポリスチレン(PS)など他の樹脂とアロイ化されて幅広く用いられています。PSとのアロイは、PPEとPSが任意の割合で完全相溶型をとることができる特性を活かし、流動性の向上と幅広い耐熱領域を実現できる代表的なポリマーアロイです。さらに非臭素系および非塩素系難燃剤で容易に難燃化できます。その他、ポリアミド(PA)、ポリプロピレン(PP)、ポリフェニレンサルファイド(PPS)、SEBS等のエラストマー等とアロイ化させることで、上記PPE樹脂の特徴にさらに各相手樹脂の特徴を付与した材料が展開されています。

PPE樹脂と他樹脂のアロイ化によって特性を改善することをmodified(変性)と呼ぶため、アロイ化した材料を変性PPE、m-PPEと称します。

2.変性ポリフェニレンエーテル(変性PPE樹脂)の製法

2-1.PPEの製法

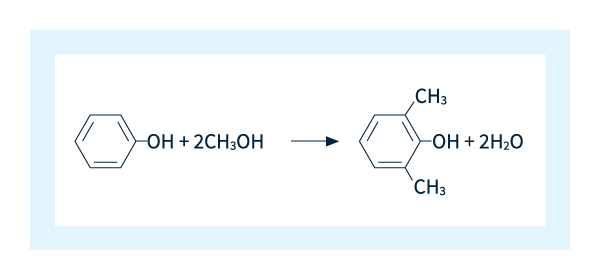

まず、フェノールとメタノールから、2,6-キシレノールを合成します。この2,6-キシレノールを基本原料とした酸化重合法(酸化カップリング法)によって、2,6-キシレノールのOH基と隣り合う2,6-キシレノールのベンゼン環の4の位置にあるH(水素)間で脱水反応が起こり、エーテルを作ることができます。この反応を繰り返すことでPPEが合成されます。

図2 2,6-キシレノールの製造方法

図2 2,6-キシレノールの製造方法

図3 PPEの製造方法

図3 PPEの製造方法

2-2.変性PPEの製法

概要でも触れたように、PPE樹脂単体では溶融時の粘度が極めて高いことから、成形加工性向上のために、他樹脂とコンパウンドしてアロイ化された変性PPE樹脂が一般的に用いられます。コンパウンドとは、目的とする性能や機能を付与するために、ベースとなる樹脂に対して他樹脂や強化材、着色用の染料・顔料、機能付与のための各種添加剤を混練する工程のことです。コンパウンドする相手材料の種類・比率等により、非常に幅広いニーズに答えることができるポリマーアロイの幅が変性PPEの特徴です。どのような種類のポリマーアロイがあるかは4.変性PPEの種類と活用分野でご説明します。Varieties and applications of modified polyphenylene ether (modified PPE) resins.

3.PPE樹脂・変性PPE樹脂の特徴

・耐熱性:

PPE樹脂はガラス転移点約210℃を有します。変性PPE樹脂ではアロイ化する材料によって、荷重たわみ温度100℃以下で流動性の優れたグレードから荷重たわみ温度200℃以上の耐熱性の優れたグレードまで、幅広い材料がラインナップされています。

・難燃性:

PPE樹脂は酸素指数(燃えるために必要な酸素量)が28と高く、難燃化しやすい樹脂です。変性PPE樹脂においてもUL94 V-0を有した、優れた難燃性を持つグレードが多数ラインナップされています。

・低比重:

PPE樹脂の比重はエンジニアリングプラスチックの中でも最も低い1.06で、軽量な素材です。

・絶縁性:

PPE樹脂は体積抵抗率が高く、絶縁性に優れます。耐トラッキング性等の電気特性を理由に採用されている製品も数多くあります。

・低吸水:

PPE樹脂は吸水率が低い樹脂です。変性PPE樹脂として、吸水による物性変化・寸法変化が小さい特徴があります。

・耐加水分解性:

変性PPE樹脂は優れた耐熱性を有しており、エステル、アミドといった構造を持たないため、耐熱水性、耐加水分解性に優れています。

・耐酸アルカリ性:

変性PPE樹脂は、酸やアルカリに対しての耐性が強い特徴があります。

・低誘電率/低誘電正接:

PPE樹脂は広い周波数域に対し誘電率や誘電正接が小さく、温度や湿度の変化にも影響されにくい特徴を有しています。変性PPE樹脂は伝送損失を小さく抑えられるため、情報通信分野にも用いられています。

・低線膨張係数:

PPE樹脂は線膨張係数がエンジニアリングプラスチックの中で最も小さく、成型収縮率が小さい樹脂です。寸法安定性、寸法精度に優れています。

4.変性ポリフェニレンエーテル(変性PPE樹脂)の種類と活用分野

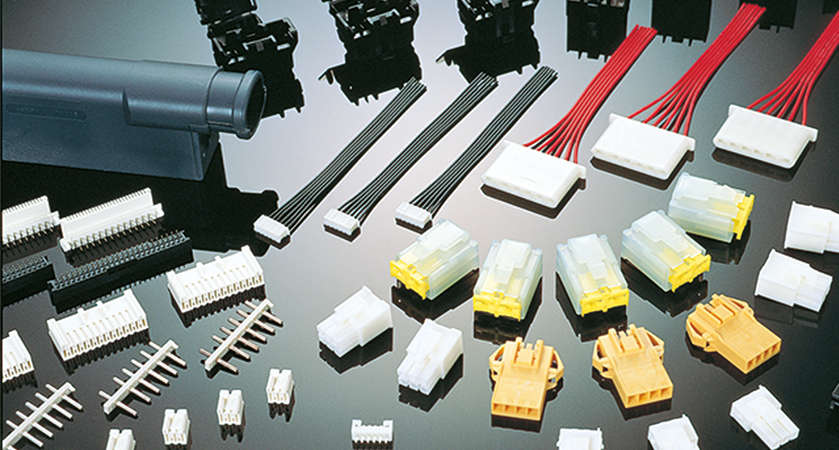

(1)PSアロイ

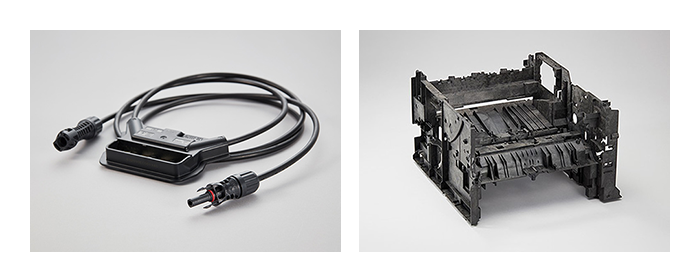

最も代表的なポリマーアロイが、ポリスチレン(PS)とのアロイです。PPEとPSは任意の割合で完全相溶型をとることができる特性を活かし、流動性の向上と幅広い耐熱領域を実現できます。非臭素系および非塩素系難燃剤で容易に難燃化でき、かつ電気特性に優れることから、電機電子部品関連で用いられます。例えば、PS比率が高い材料は流動性に優れることから電気製品の筐体など大型の成形品に使用することが可能です。一方、PPE比率が高いグレードは耐熱性に優れ、太陽光発電用ジャンクションボックス等に使用されています。

また、ガラス繊維等のフィラーをコンパウンドすることによって、強度・剛性・寸法精度を向上できます。フィラー強化グレードは、例えば、変性PPE樹脂の寸法安定精度を理由にOA・プリンター等の精密機器の筐体への採用や、対加水分解性を理由にポンプや混合栓等の給排水用途等に広く使用されています。

近年では、低比重・耐熱性・寸法安定性を活かした車載電池用途や、低誘電率・低誘電正接を活かした次世代通信用途への活用が広がっており、さらなる市場拡大が期待されています。

事例:左)太陽光発電コネクタ、右)OAプリンター筐体

事例:左)太陽光発電コネクタ、右)OAプリンター筐体

(2)PAアロイ

ポリアミド(PA)は耐熱性・強度・耐油性に優れた、自動車部品に広く使用されているエンジニアリングプラスチックです。一方で吸水しやすい特性があり、使用環境によっては物性変化・寸法変化がみられる点に注意が必要です。PPEはほとんど吸水しないため、PPEをPAにアロイすることによって、PAの吸水率を大きく下げることができ、PAの弱点を補うことができます。この特性を活かし、PAアロイ材料は自動車の電装部品等に使用されています。

事例:車載リレーブロック

事例:車載リレーブロック

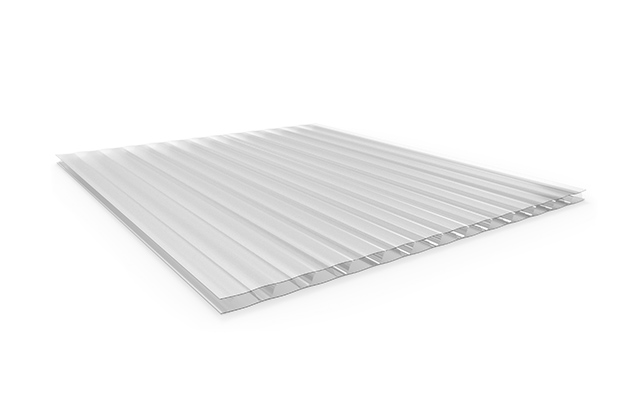

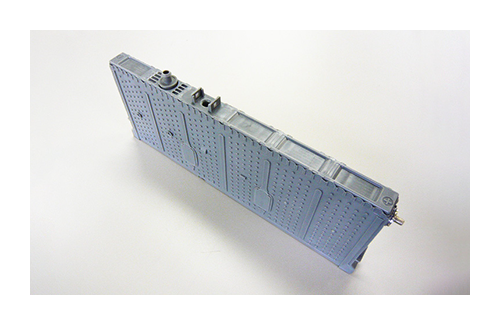

(3)PPアロイ

ポリプロピレン(PP)は低比重・耐油性・耐薬品性・強度靭性等、バランスの優れた汎用プラスチックです。PPとPPEのアロイ材料は、通常のPPに比べ、耐熱性、寸法精度等を向上させており、車載バッテリー用途などに適用されています。

事例:NiMH電池ケース

事例:NiMH電池ケース

(4)スーパーエンジニアリングプラスチックアロイ

さらなる高耐熱材料であるスーパーエンジニアリングプラスチックのポリフェニレンサルファイド(PPS)、ポリフタルアミド(PPA)とのアロイ材料も開発されています。PPSアロイにおいてPPSに比べて寸法安定性・反り改善等が、PPAアロイにおいてはPPAに比べて低吸水化、吸水時の物性・寸法変化の抑制が特徴となっています。

このように、変性PPE樹脂は様々な優れた特徴を持つアロイ材料を有しており、幅広い用途で使用されています。

→ 旭化成の変性PPE樹脂「ザイロン™」のグレードラインナップはこちら

→ 旭化成の変性PPE樹脂「ザイロン™」の用途事例・活用提案はこちら

5.変性ポリフェニレンエーテル(変性PPE樹脂)の成形加工法、使用上の注意事項

変性PPE樹脂のほとんどが成形されている射出成形についての一般論をご説明します。高品質の成形品を得るためには、溶融樹脂の温度を適切に設定し、成形時に十分流動し、かつ熱劣化しないようにすることが肝要です。流動性や耐熱性の異なるグレードがあるため、適正な温度は一概には言えませんが、流動性が不十分だと成形が出来なかったり、成形品のひずみが大きくなったりします。また、温度が高すぎると劣化しガス発生や変色の原因になります。

成形中の劣化は水分、他の樹脂などの異物の存在、そして長時間滞留によって促進されます。適切な大きさの成形機を選び、無理のない成形条件を設定してください。

同じ理由から、金型ではランナを太目にすること、ガスベントを設けることが求められます。また、離型剤や、金型に使われている潤滑油がクラックの原因になることがあります。このため、抜き勾配を十分とり、離型剤の使用を出来るだけ避けて下さい。離型剤を使用する場合は、技術ハンドブック11. 耐薬品性を参考にして下さい。Chemical resistance特に変性PPE樹脂においては、油脂分等の付着はクラック発生の原因になることが多いため、加工中の機械油の付着、離型剤の選定、使用中のスプレー、洗浄剤など影響に注意してください。

以上述べてきたことをまとめると下項のようになります。

・成形材料は適切な条件で乾燥する

・成形機はショット量に合ったものを選ぶ

・局部的な高温や、高いせん断力が加わらないような条件で可塑化する

・成形機は手入れを十分行い、異常高温部、異物の残留、滞留部のないようにする

・再生材を使用する時は十分乾燥し、異物が混入しないようにする

・抜き勾配を十分とり、離型剤の使用を控える

*旭化成の変性PPE樹脂「ザイロン™」の使用上の注意事項については以下ご参照ください

→ 製品設計基準

→ 技術ハンドブック(7. 成形品の設計基準、8. 金型設計、9. 成型上の留意点、10. 二次加工性、11. 耐薬品性)

6.変性PPE樹脂のサステナビリティ対応

これまでご説明してきたように、PPEは耐熱性に優れ、加水分解もしにくいことから、製品使用中の性能劣化が少なく、スプルー・ランナー等の端材のリグライド時物性の低下が少ない樹脂です。この特徴から、リサイクル・再生利用時にも性能保持しやすい樹脂とも言えます。

変性PPEのサステナビリティ対応には、大きく2つの方向性があります。

6-1.PPEのバイオマス化

PPEの原料であるフェノール、メタノールは通常化石燃料から製造されますが、バイオマス原料由来のフェノール、メタノールを使用することで、PPEのバイオマス対応が可能です。

ここで、よく用いられるスキームがマスバランス方式です。これまで化石燃料由来の製品を作ってきた工場で、いきなりバイオマス原料を100%使用した製品生産は現実的に難しいです。マスバランス方式では、バイオマス原料と化石燃料由来の原料が製造工程内で混ざっても、投入したバイオマス原料の割合に応じてバイオマス製品を割り当てることが認められた管理手法です。

→ 旭化成のPPEのバイオマス化への取り組み「Asahi Kasei Plastics SingaporeにてISCC PLUS認証を取得」はこちら

6-2.変性PPEのアロイ相手である、ポリスチレン、ポリアミド等の樹脂のリサイクル材料もしくはバイオマス材料の使用

相手材となる、ポリスチレン、ポリアミド等の樹脂でも既にバイオマス由来の原料もしくは、リサイクル・再生材が用いられています。これらの相手材を活用することで、環境負荷を引き下げることも行われています。

→ 旭化成の変性PPE樹脂「ザイロン™」のリサイクルグレード開発はこちら

コラム:混ざりやすくする工夫

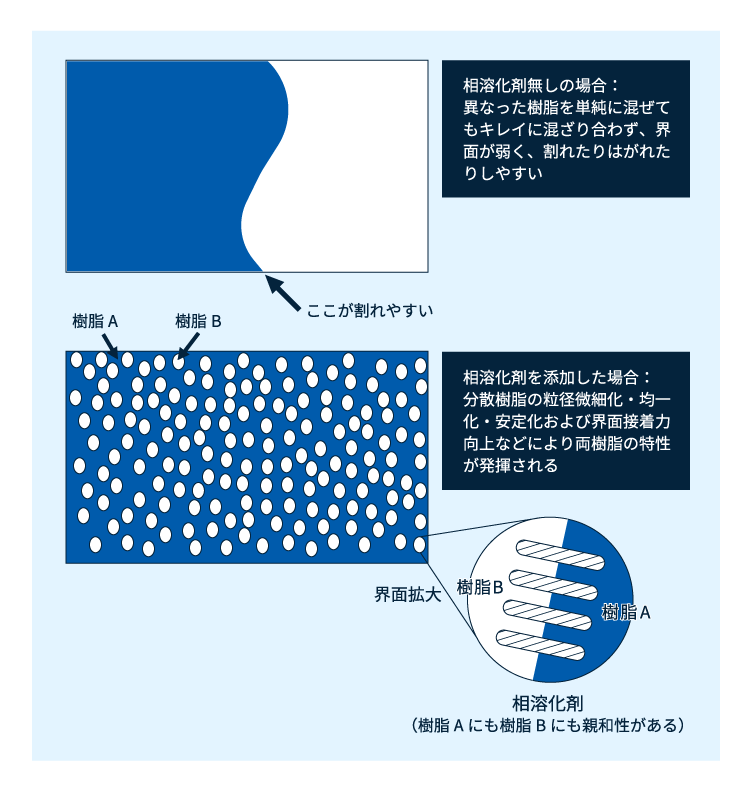

多様な要求に応える手段として、ポリマーアロイがあります。ただし、どの組み合わせでもうまく混ざりあうとは限りません。うまく混ざらないと界面からはがれたり、割れたりしてしまい、かえって性能が低下してしまいます。

すでに説明しましたように、PPEとポリスチレン(PS)は極めて混ざりやすい組み合わせです。このような例は他には見られません。混ざりやすさの目安には「sp値」と言う指標が使われます。PPEとPSはこの値が極めて近いため、混ざりやすい組み合わせになります。

混ざりにくい素材同士を混ざりやすくすることも出来ます。「相溶化剤」の添加です。この相溶化剤はどちらの材料とも混ざりやすい特性を持った物質が選ばれます。図4に示すように、材料Aにも材料Bとも相性が良いためどちらにも溶け込み、結果としてA、B両材の混和を助けます。

変性PPEでも、PA+PPEやPP+PPEの系では相溶化剤が使われています。

図4 相溶化剤の役割

図4 相溶化剤の役割

(執筆:佐藤功、佐藤功技術事務所)

旭化成では、変性PPE樹脂「ザイロン™」をはじめ、各種エンプラ製品の豊富なグレードラインナップと独自の技術力で、製品の性能向上を実現します。ご質問・ご相談・サンプルのご依頼など、お気軽にお問い合わせください。

製品・技術に関するご質問、サンプルのご依頼をお待ちしています