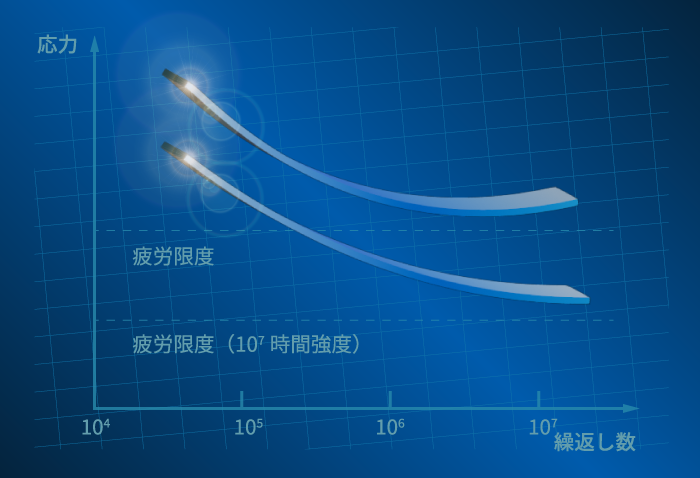

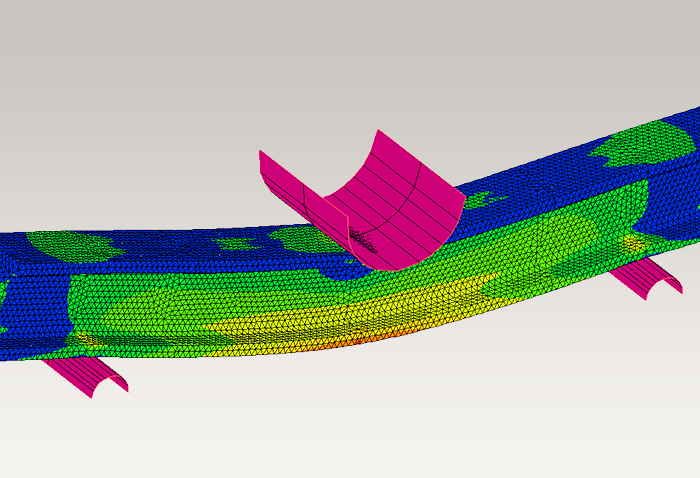

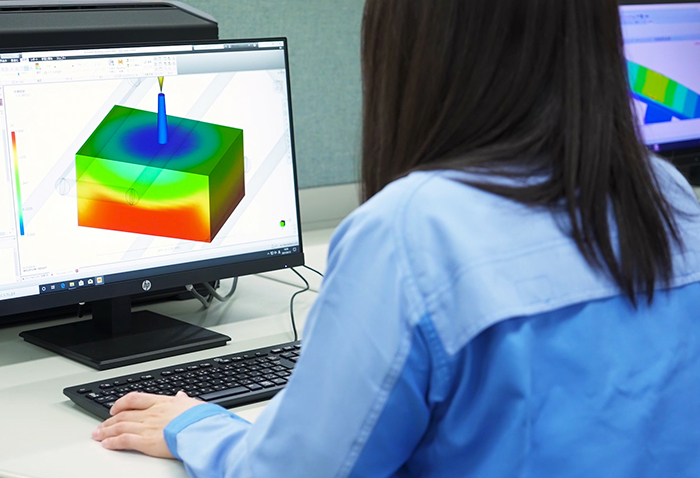

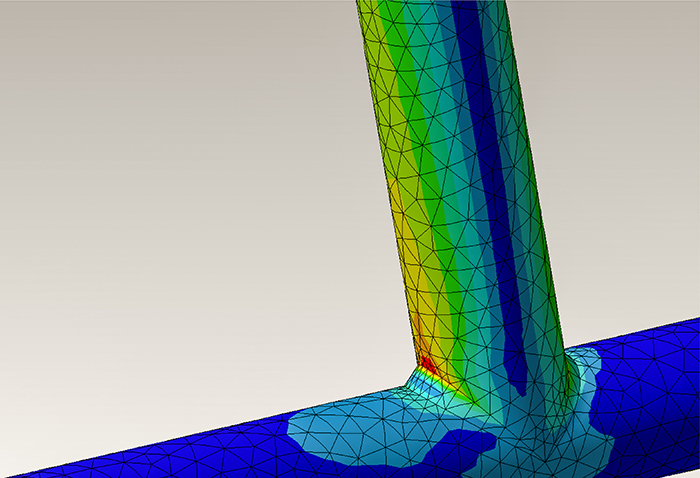

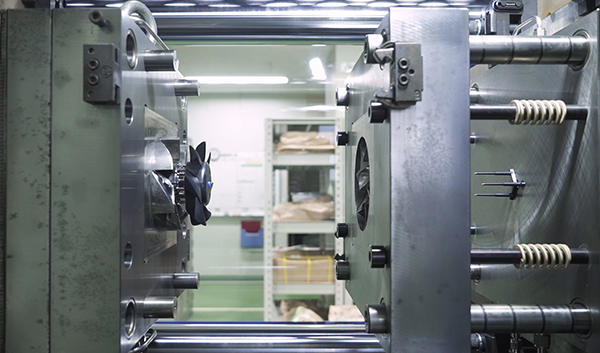

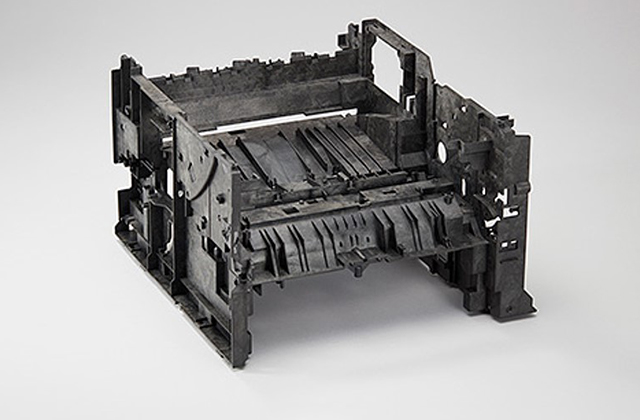

In designing resin parts, durability and reliability can be improved by properly evaluating fatigue and creep properties and reflecting them in analysis. In this part, we will explain the fatigue and creep properties of plastics and how to analyze them.