- TOP

- Fundamentals of CAE

- Part 9 Orientation in fiber-reinforced plastic

Series: Fundamentals of CAE Analysis for Plastic Product Design

Part 9 Orientation in fiber-reinforced plastic

Injection molding analysis can predict the orientation of fiber reinforcement (fibrous filler) in injection molding. This article explains what fiber reinforcement orientation is in injection molding and the importance of understanding the orientation.

Contents

| 1. What is fiber reinforced plastic? |

| 2. What is the orientation of fiber-reinforced plastic? |

| 3. What is the orientation tensor? |

| 4. Fiber orientation result format |

| 5. Summary |

What is fiber reinforced plastic?

Fiber-reinforced plastic is a material that contains reinforcing materials such as glass-fiber to improve the mechanical strength of the resin and to provide functionality. There are various types of fibrous reinforcing materials that can be used, such as glass-fiber, carbon fiber, aramid fiber, and natural minerals, and the type and amount of reinforcing materials are selected based on the purpose, cost, and environmental performance.

[Examples of fiber-reinforced materials]

■ Glass-fiber (GF)

Resins containing GF have excellent strength and compressive strength and improved dimensional stability.

Examples of use: Automobile bumpers and door panels, ship hulls, sporting goods such as golf clubs and fishing rods, etc.

■ Carbon fiber (CF)

Resins containing CF are lightweight, have excellent mechanical strength, and provide high stiffness. They also have excellent sliding properties and abrasion resistance. Because they are conductive, they are used when electrical properties are required.

Examples of use: Automobiles, aerospace, building materials, sporting goods, etc.

■ Aramid fiber (AF)

Resins containing AF are lightweight, strength, and have excellent durability. They have extremely high impact resistance, toughness, and abrasion resistance. They also have a very low coefficient of thermal expansion. However, they are a very expensive reinforcement material compared to GF and other materials.

Examples of use: bulletproof equipment such as bulletproof helmets and military vehicle armor, automobile structural parts, bicycle frames, tennis rackets, etc.

■ Natural minerals

When natural minerals such as hydrated magnesium silicate fiber (sepiolite) and calcium silicate fiber (wollastonite) are used as reinforcing materials, it becomes a plastic with excellent heat resistance, abrasion resistance, etc. Compared to GF, it has excellent dimensional stability due to its smaller aspect ratio.

Examples of use: tableware, office equipment, automobile parts, etc.

What is fiber reinforced plastic orientation?

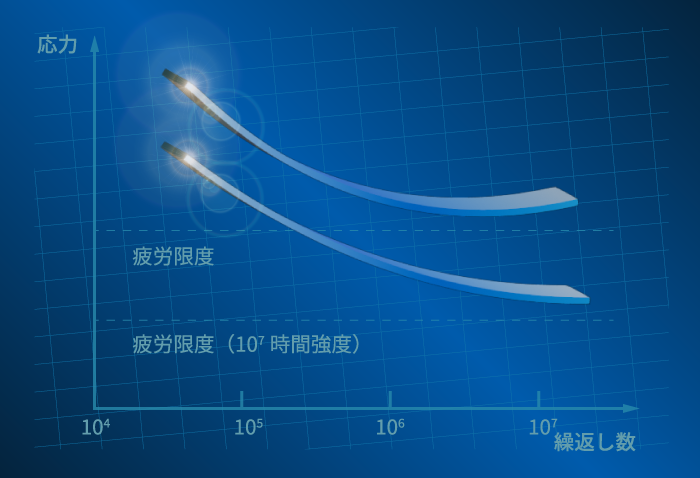

Since reinforcing materials are fibrous, orientation occurs during injection molding, which affects the material properties. Orientation means that the fibers are aligned in a certain direction. Non-reinforced materials have material properties that are independent of direction, which is called isotropy, whereas material properties that change depending on direction are called anisotropy. Generally, plasitcs that contain fiber reinforced materials tend to show significant anisotropy. An example is shown below.

- Mechanical strength: strength and stiffness change significantly depending on orientation

- Warpage: The fibers are restrained, causing anisotropy in shrinkage and warpage.

- Thermal conductivity: The thermal conductivity of the fibers used differs from that of the resin, so the thermal conductivity changes depending on the orientation.

As such, the orientation has a large effect on material properties, so when using fiber-reinforced resins, it is important to understand the orientation from the design stage.

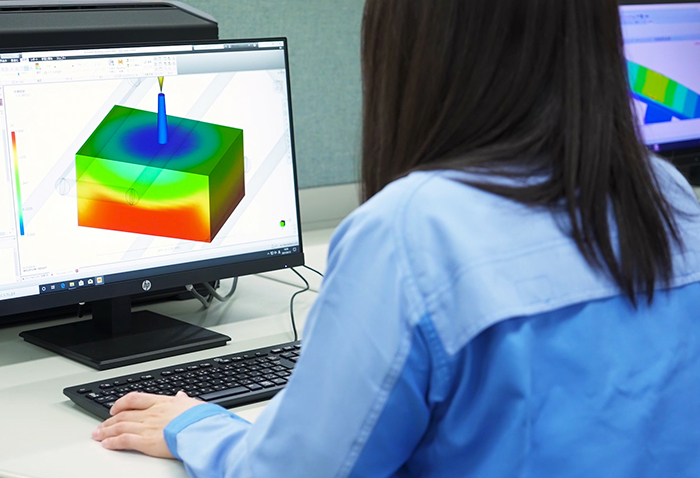

In injection molding analysis, the orientation of the fibers can be analyzed. Fiber orientation is affected by molding conditions, material behavior, and fiber aspect ratio and concentration. If the behavior of the fibers in the resin is not properly considered, the orientation prediction will be far from the reality, so it is necessary to check the analysis input conditions.

What is the orientation tensor?

The orientation tensor is a probability distribution that indicates the degree to which the fibers are oriented in a three-dimensional coordinate system. The closer the value is to 1 for a specified axis, the more the fibers are aligned along that axis, and the sum of the three axis values is 1. In other words, the fiber orientation tensor has information on the direction and ratio.

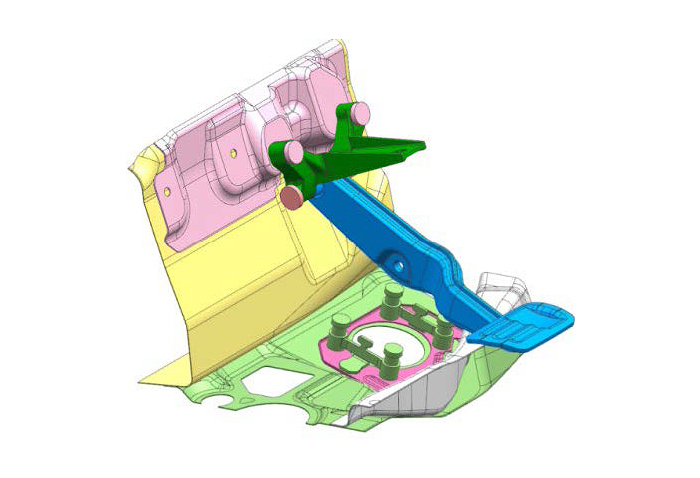

In a thin plate with a simple shape, the fibers are strongly oriented in the flow direction. As the plate becomes thicker, the fibers tend to be oriented in the flow direction in the surface layers, but in the middle layers, they tend to be oriented perpendicular to the flow direction or randomly, as shown in Figure 1. In this way, the local orientation distribution can be expressed using the orientation tensor, but this requires an accurate flow pattern.

.gif) Fig. 1 Differences in orientation of fiber reinforcement in the surface and middle layers

Fig. 1 Differences in orientation of fiber reinforcement in the surface and middle layers

Fiber orientation result format

The fiber orientation is output as an orientation tensor for each part. As mentioned above, it is necessary to take the fiber orientation into account in order to accurately predict strength of the part.

■ Example using a flat plate

.png) Fig. 2 Comparison of fiber orientation tensor analysis results and experimental values

Fig. 2 Comparison of fiber orientation tensor analysis results and experimental values

A comparison between the analysis results and the actual measured values for a flat plate is shown in Figure 2. As shown in the upper illustration of Figure 2, in the surface layers (front and back sides) of the plate, the fibers are mostly oriented in the flow direction (X-axis direction), while in the middle layer (center of plate thickness), the fibers are mostly oriented in the direction perpendicular to the flow (Y-axis direction), resulting in a different fiber orientation distribution between the surface and middle layers.

In addition, understanding the degree to which the actual molded product and the analysis results match is important for improving prediction accuracy. In these verifications, the results will also change if the aspect ratio or content of the fiber is changed. It is important to use material data for analysis for the target material.

Here is a concrete example of how the fiber orientation results are used:

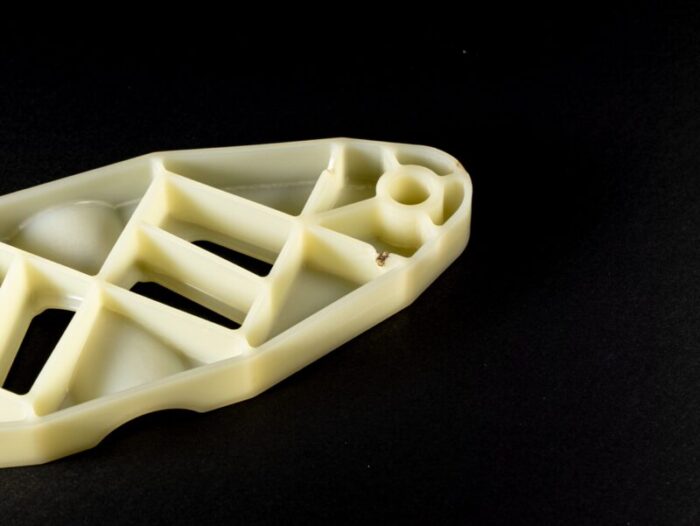

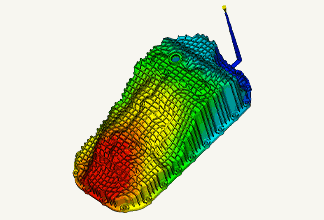

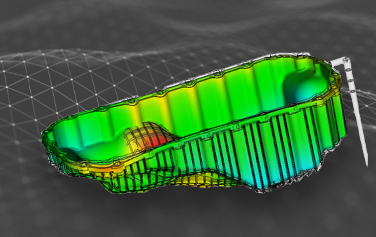

■ Example of warpage analysis

Fiber orientation is also important in warpage analysis. The anisotropy of resin shrinkage due to orientation is calculated for each part, and the state of warpage is calculated based on the results. These are built into injection molding analysis software, so when using fiber-reinforced plastic, it is necessary to check the degree of warpage caused by fiber orientation and whether there are any problems with the specifications. One effective way to resolve warpage is to change the filling pattern by changing the gate position, etc.

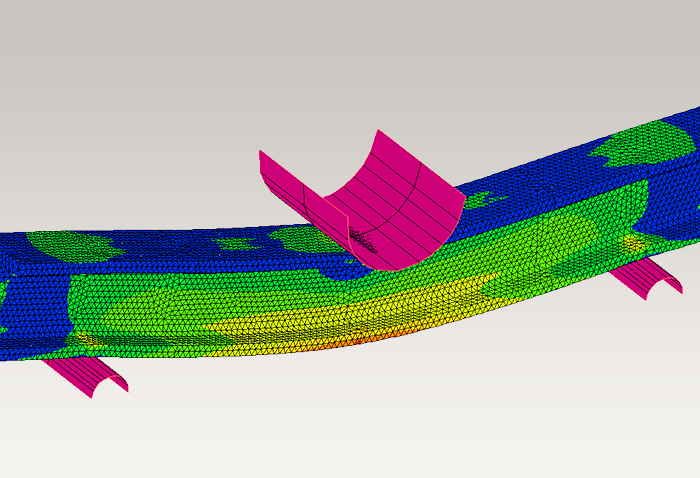

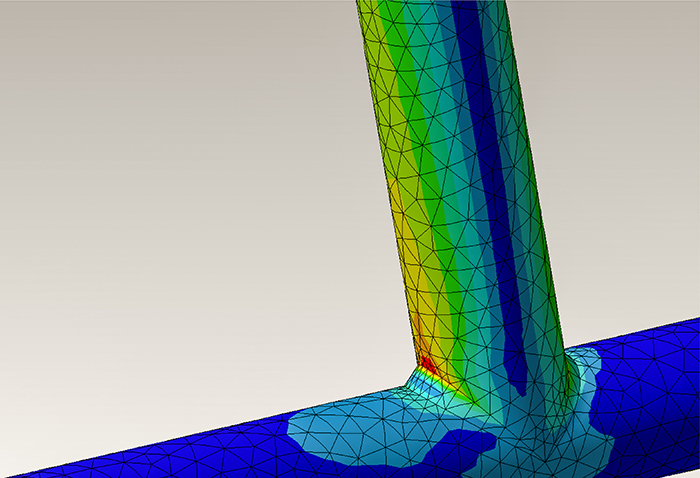

■ Use in structural analysis

Depending on the orientation of the fibers, strength and stiffness become anisotropic. With fibrous reinforced plasitcs, the reinforcing effect is greater in the direction in which the fibers are aligned. Since there are differences in physical properties between the flow direction of the fibers and the direction perpendicular to the flow direction, the characteristics of the reinforcing fibers can be fully utilized by ensuring that strength and stiffness are obtained in the direction where strength is particularly required at the design stage.

.png) Fig. 3 Images of tensile test specimens cut at different angles (left) and stress-strain curves (right)

Fig. 3 Images of tensile test specimens cut at different angles (left) and stress-strain curves (right)

In the actual molded product, the orientation tensor of each part output by the injection molding analysis is mapped onto a model for structural analysis, and analysis is performed using the material data for structural analysis. Specifically, as shown in Figure 3, strength tests are performed on test pieces cut at different angles from a flat plate obtained by injection molding, and material data for structural analysis is created based on the correlation with the orientation tensor. This brings the structural analysis closer to the behavior of the actual molded product, and is used in the design.

Summary

The physical properties of plastics containing fiber reinforcement change depending on the fiber orientation. While the use of fiber reinforcement improves strength and stiffness, and contributes to weight reduction by replacing metals, it can also cause problems such as warping. For this reason, designers and material selectors need to understand the characteristics of fiber reinforcement and use injection molding analysis to predict and take measures in advance, which leads to improved design quality.

◆You can receive the latest release information by email. Register here.

For more information about CAE, please contact us.

CAE Download Slides