Heat resistance

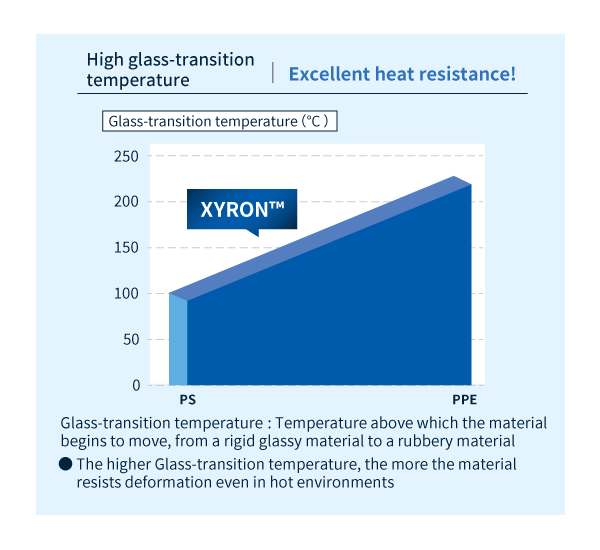

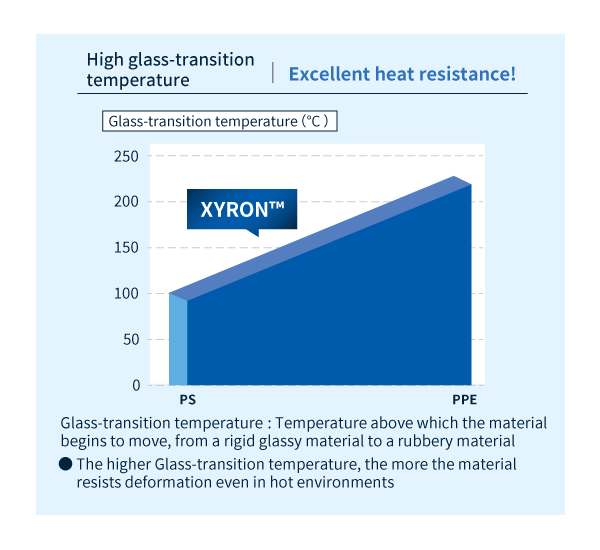

XYRON™ modified PPE resins offer excellent heat resistance, with high glass-transition temperatures in the range 90–220°C.

NEW SERVICE!

CAE ServicesFor inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

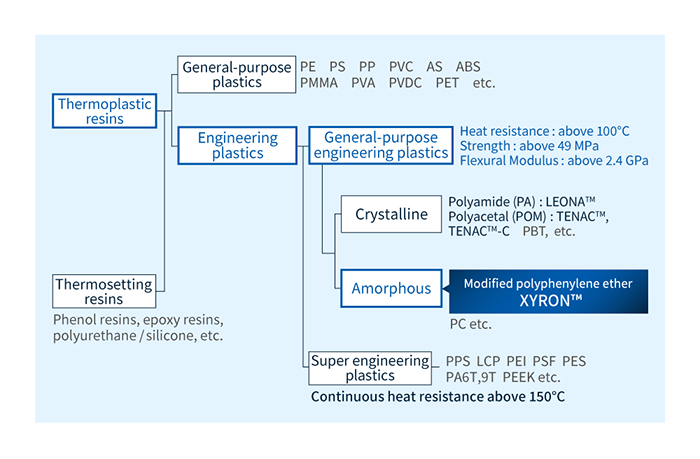

XYRON™ is Asahi Kasei's family of modified PPE (modified polyphenylene ether or mPPE) resin products.

Modified PPE resins are polymer alloys formed by compounding PPE resins with other types of resin. PPE resins are engineering plastics featuring excellent heat resistance, flame retardance, electrical properties, and dimensional stability, with low water absorption and low specific gravity. PPE resins are amorphous thermoplastic resins.

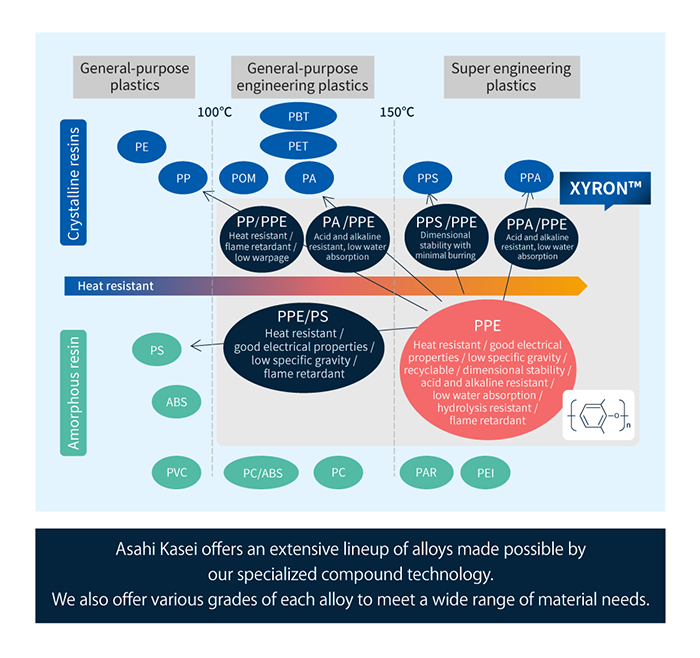

Asahi Kasei uses 2,6-xylenol as a raw material to produce PPE, and then to form alloys and compounds with other resins to yield an extensive lineup of material grades. For each type of alloy, we offer various grades to meet a diverse range of customer needs, making us Asia's No. 1 manufacturer* of modified PPE resins.

*Source: Sales volume from Fuji Keizai's 2023 Engineering Plastics Market Outlook and Global Strategy.

XYRON ™ is Asahi Kasei's family of modified PPE resins. These products are classified as engineering plastics featuring outstanding heat resistance and mechanical strength.

PPE resins are amorphous thermoplastic, and XYRON™ modified PPE resins are engineering plastics boasting the following key properties.

XYRON™ modified PPE resins offer excellent heat resistance, with high glass-transition temperatures in the range 90–220°C.

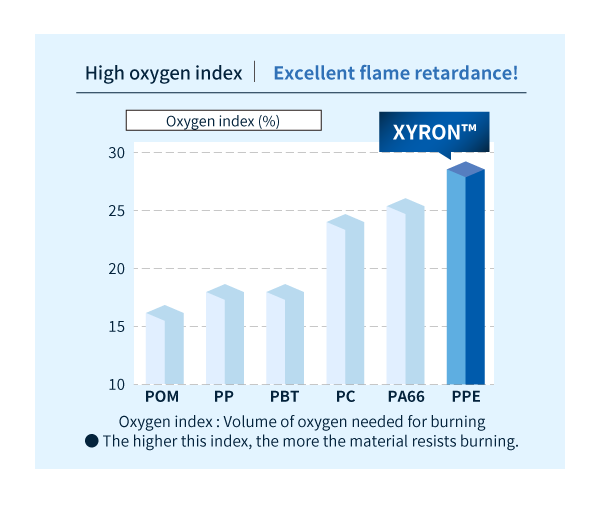

XYRON™ resins have a high oxygen index (a measure of the volume of oxygen required for burning), making them highly flame retardant.

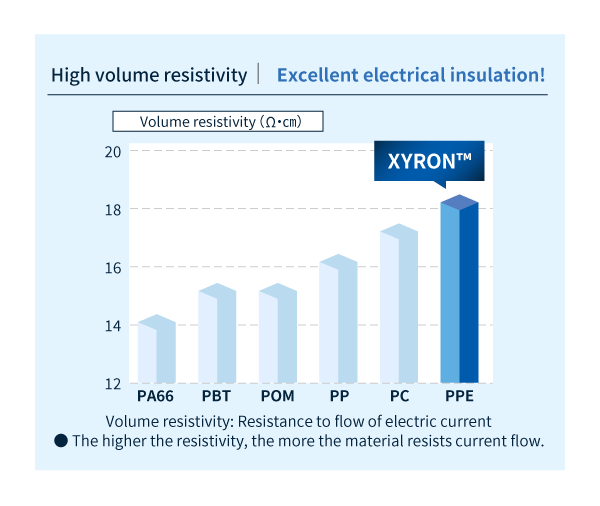

XYRON™ modified PPE resins have high volume resistivity (a measure of resistance to the flow of electric current), making them highly electrically insulating.

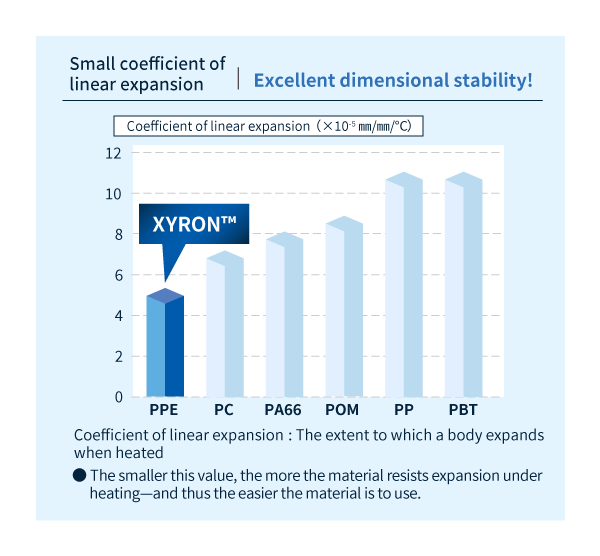

XYRON™ modified PPE resins have low mold shrinkage, ensuring excellent dimensional stability and dimensional precision.

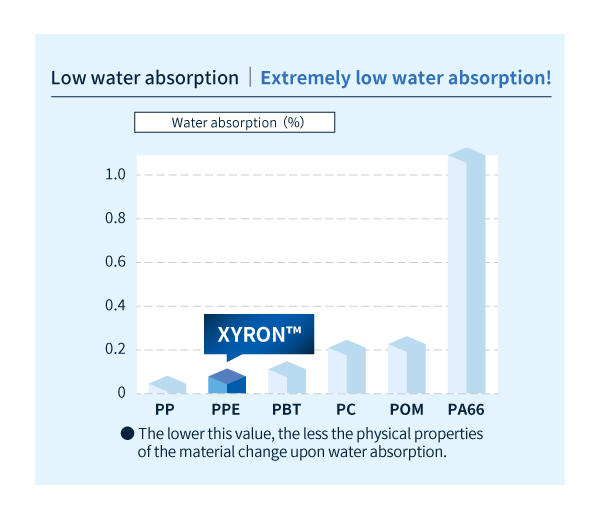

XYRON™ modified PPE resins boast low water absorption, ensuring minimal variation in product dimensions and physical properties due to water absorption. These materials also offer excellent hydrolysis resistance, and ability to withstand acid and alkaline exposure, making them highly durable in harsh environments.

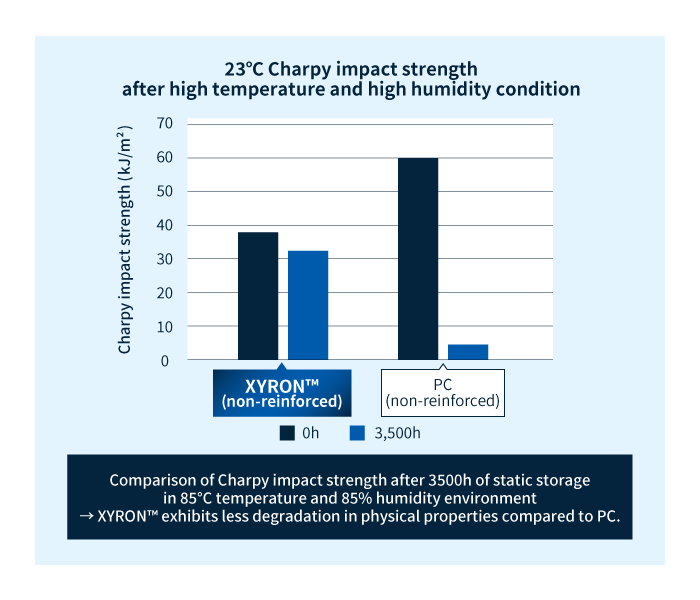

In addition, it has excellent heat resistance, which means it also has excellent resistance to hot water and hydrolysis. The table below shows that XYRON™ shows little deterioration in its physical properties in terms of Charpy impact strength after being left in a high-temperature, high-humidity environment for 3,500 hours.

In addition, it is highly resistant to acids and alkalis, and has excellent environmental durability.

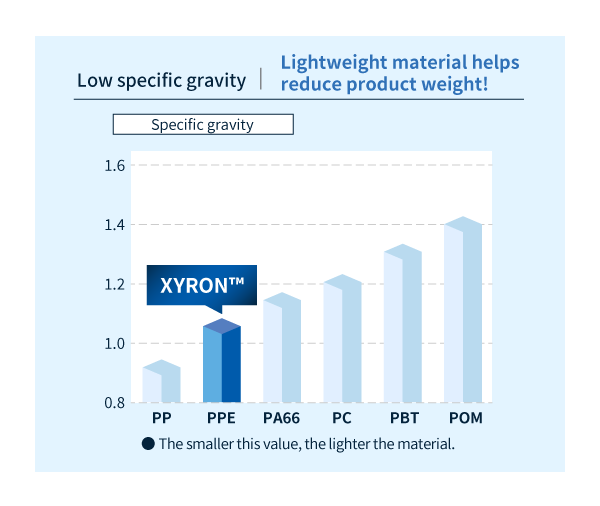

XYRON™ modified PPE resins are lightweight materials boasting the lowest specific gravities of all engineering plastics.

Choosing XYRON™ resins helps to reduce component weights.

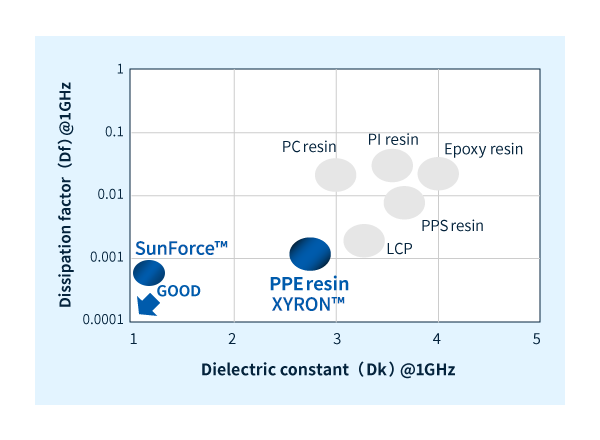

PPE, the main raw material of XYRON ™ modified PPE resins, features low dielectric constant (Dk) and low dissipation factor (Df), ensuring minimal transmission losses and making these materials ideal for use in information and communication technologies. The high glass-transition temperature of PPE also ensures that the temperature dependence of the dielectric permittivity is lower for XYRON ™products than for other heat-resistant resins.

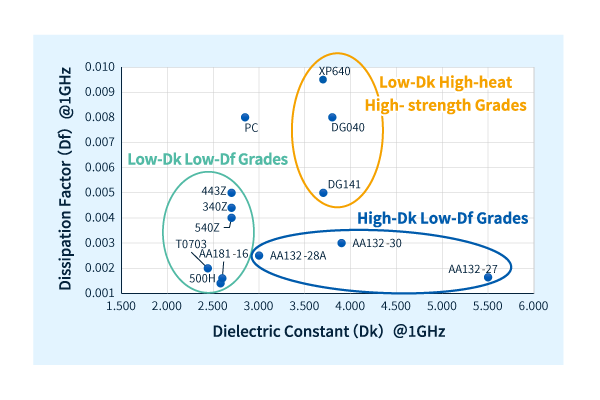

XYRON ™ modified PPE resins combine the low dielectric permittivity of PPE with the advantages of Asahi Kasei's compound technology to support a wide range of dielectric permittivity needs. In particular, we offer dielectric constant (Dk) / dissipation factor (Df) controlled grades providing a wide range of dielectric permittivity, including grades combining high dielectric constant (Dk) and low dissipation factor (Df).

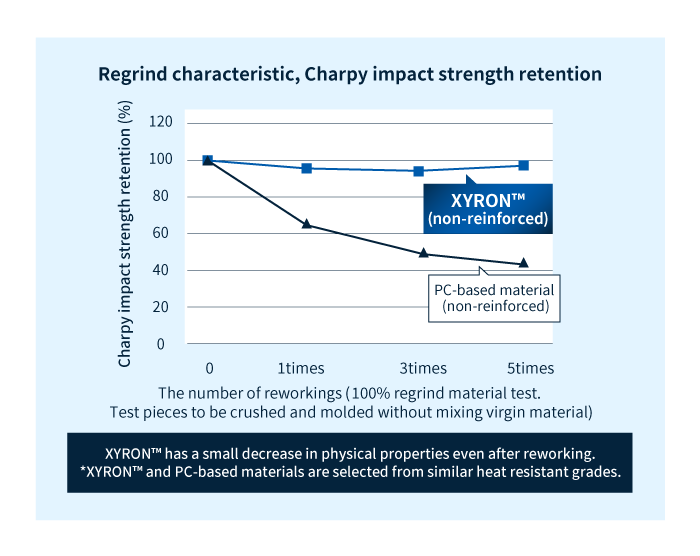

The excellent heat resistance and hydrolysis resistance of XYRON™ modified PPE resins ensure that these products exhibit minimal variation in physical properties upon recycling and regrinding, making these materials easy to reuse.

Also, the light weight of XYRON ™resins—which boast the lowest specific gravities of all engineering plastics—reduces the volume of material needed for product manufacturing. Together with the ease of recycling, this ensures that the choice of XYRON ™ resins reduces material-use volumes at every stage of the product cycle, helping to reduce environmental impact.

XYRON™ modified PPE resins are compounds combining PPE with other types of resin.

Asahi Kasei uses 2,6-xylenol as a raw material to produce PPE, and then forms polymer alloys by compounding with various other resins—including polystyrene (PS), polyamide (PA), polypropylene (PP), polyphenylene sulfide (PPS), and polyphthalamide (PPA)—to yield an extensive lineup of material grades. For each type of alloy, we offer various grades to meet a diverse range of customer needs, making us Asia's No. 1 manufacturer* of modified PPE resins.

*Source: Sales volume from Fuji Keizai's 2023 Engineering Plastics Market Outlook and Global Strategy.

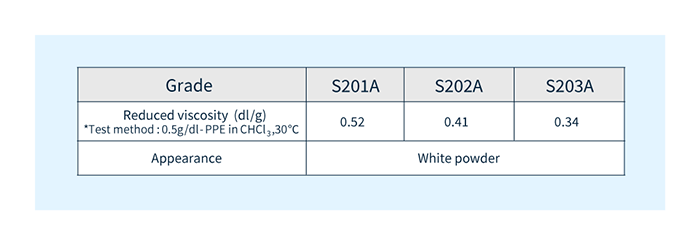

In addition, the modified PPE resin XYRON™ is also available as a "PPE raw material (PPE powder)" in which the main material, PPE, is not compounded with other resins.

PPE raw materials are amorphous polymers that have high heat resistance, low specific flame resistance, excellent electrical properties and flame retardancy, and excellent compatibility with polystyrene.

With offices in many countries around the world, Asahi Kasei supports our customers on a global basis.

Moreover, our “resin CAE technology” service—Asahi Kasei's in-house design-simulation expertise—is available to support customers in the product design and development stages.

→ Click here for details on Asahi Kasei's technical support

Asahi Kasei offers a wide range of lineup of XYRON ™ PPE/PS grades featuring various levels of flame retardance and heat resistance, as detailed in the table below. Different choices of filler materials, optimized as requested, also yield grades boasting various mechanical properties (including rigidity, toughness, low warpage, and dimensional stability), conductive grades, the V-series of grades boasting excellent vibration resistance and acoustic noise reduction, and the W-series of grades specialized for water-supply applications.

XYRON™ alloy grades—alloys combining PPE with a wide range of crystalline resins, from general-purpose materials to super engineering plastics—combine the advantages of PPE with the features of different crystalline resins, from heat resistance to chemical resistance. Our lineup includes: PP/PPE products boasting excellent chemical resistance and low warpage; PA/PPE products boasting heat resistance, low water absorption, and oil resistance; PPS/PPE products boasting high heat resistance, minimal burring, and low warpage; and PPA/PPE products boasting high heat resistance and low water absorption.

Click the entries in the table below for detailed information on each material grade—or click the buttons to see the features of each product series.

Asahi Kasei also offers bare PPE resins (powders) before blending with other resins to yield compound materials. Please contact us to learn more about this option.

Asahi Kasei is also working to achieve carbon neutrality for XYRON™ products by developing renewable attributed PPE and recycled grades containing 15-40% post-consumer recycled (PCR) plastics.

Please contact us to ask any questions, discuss any concerns, and request samples.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.