エンプラ基礎知識

PFAS規制に対応し、フッ素樹脂を超える摺動性を発揮

フッ素樹脂は摺動特性に優れた材料として広く使用されてきましたが、PFAS規制で使用制限される可能性があります。

旭化成は、独自の摺動技術を活用し、レオナ™ PFASフリー摺動グレード(開発品)を開発しました。

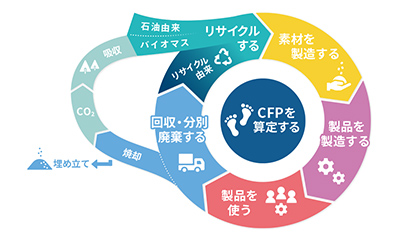

この新グレードは、フッ素樹脂以上の摺動性を有するポリアミド樹脂として、PFAS規制に対応するソリューションとして環境負荷低減に貢献します。

樹脂CAE

SDS・各種化学物質調査のお問い合わせは

お取引商社様経由など

購入ルートに沿ってのご依頼をお願いしております。

ご了承とご協力のほどお願いいたします。

PFASはペルフルオロアルキル化合物およびポリフルオロアルキル化合物(Per- and Polyfluoroalkyl Substances)の総称であり、少なくとも1つの完全にフッ素化されたメチルまたはメチレン基(水素、塩素、臭素、ヨウ素が結合していない)を含むフッ素化合物と定義されています。

現在、一部のPFASは、環境や人体への影響などが懸念され、国連、欧州、米各州等の全世界で規制の枠組みが議論され、成立している状況です。

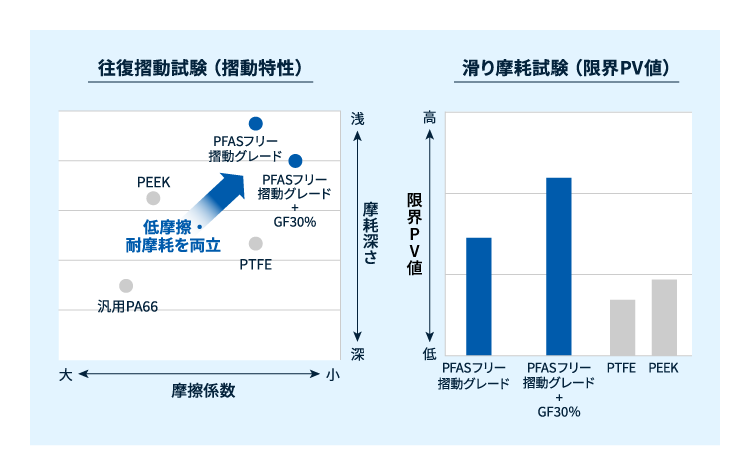

レオナ™ PFASフリー摺動グレード(開発品)は、旭化成の独自の摺動技術を活用して、フッ素樹脂を超える摺動性を実現するグレードです。自動車・航空宇宙・ロボット部品、建築資材、スポーツ用品など、幅広い用途でのPFAS規制対応を可能にします。

フッ素樹脂は摺動特性に優れた材料として広く使用されてきましたが、PFAS規制で使用制限される可能性があります。

旭化成は、独自の摺動技術を活用し、レオナ™ PFASフリー摺動グレード(開発品)を開発しました。

この新グレードは、フッ素樹脂以上の摺動性を有するポリアミド樹脂として、PFAS規制に対応するソリューションとして環境負荷低減に貢献します。

レオナ™ PFASフリー摺動グレード(開発品)は、フッ素樹脂を配合せずに、ポリアミド樹脂の幅広い材料設計に摺動性を付与できるため、設計の自由度が高まります。

フッ素樹脂を超える摺動性を発揮しながら、多様な特性を追加することで、自動車・航空宇宙・ロボット部品、建築資材、スポーツ用品など、幅広い用途での使用が可能です。

モーターから得た回転速度を減速・変速させ、必要な力を得るための変換機

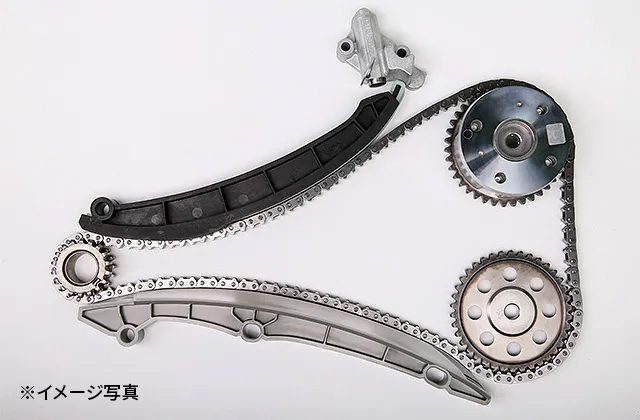

自動車エンジンタイミングチェーンのサポート部品。

駆動するチェーンに接するため、摩擦・摩耗特性が求められる。

:

:

1442、PFASフリー摺動グレード(開発品、詳細はお問い合わせください)

ギアは動力を伝達する重要な部品。自動車、産業機械、航空などの幅広い分野で使用されており、低摩擦性・耐摩耗性・耐熱性が求められる。

※イメージ写真

※イメージ写真

:

:

15G20、PFASフリー摺動グレード(開発品、詳細はお問い合わせください)

エンプラ基礎知識

プレスリリース

レオナ™に関するご質問・ご相談・サンプル

のご依頼をお待ちしております。