Solutions

Excellent Flowability

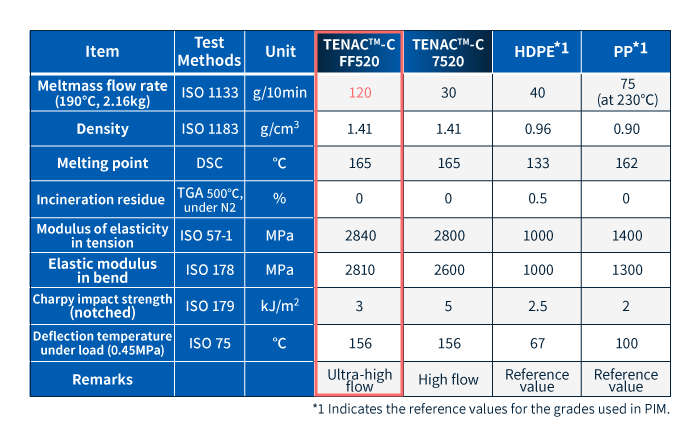

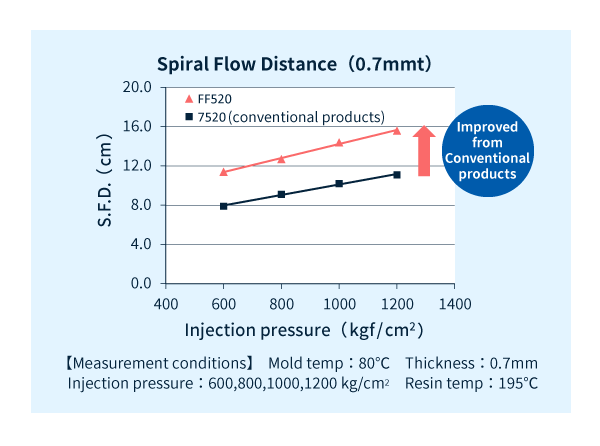

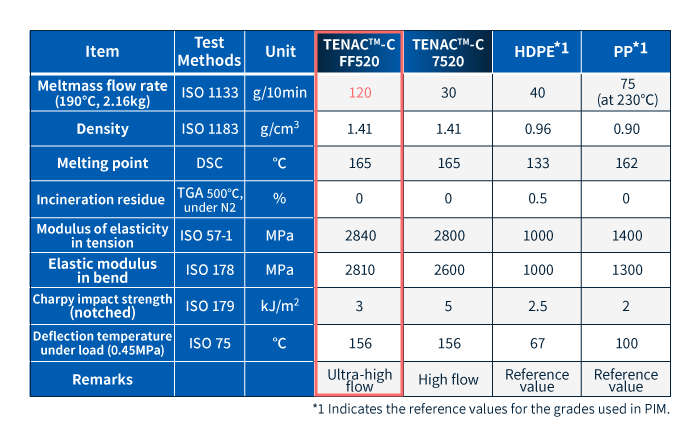

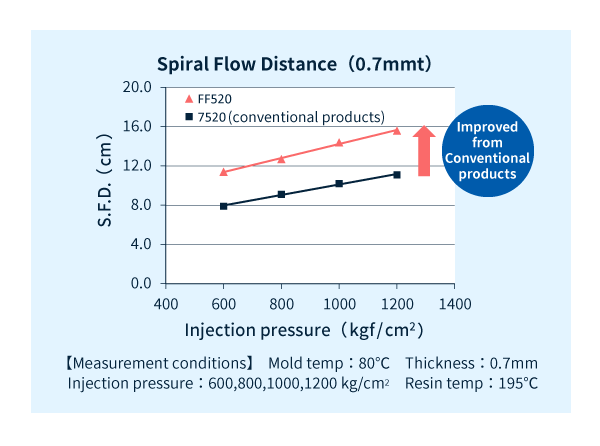

As shown in the table below, TENAC™-C FF520 exhibits higher flowability compared to our conventional high-flow grade product. It’s available for your complicated and thin shapes.

NEW SERVICE!

CAE ServicesFor inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

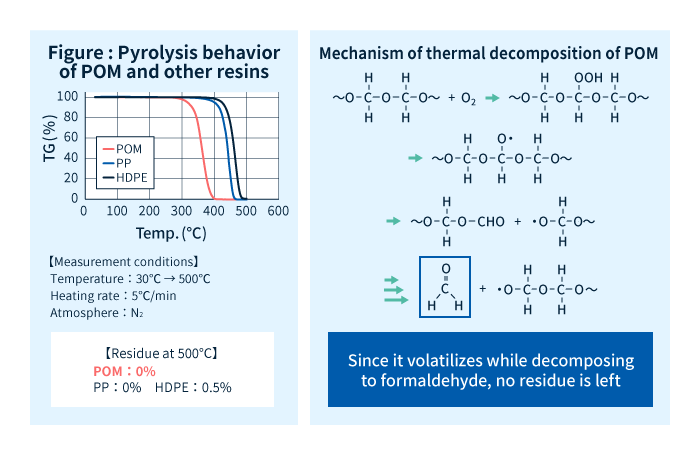

In PIM technology, polyacetal (POM) is used as a resin constituting a binder due to the high strength of POM itself as well as the advantage that it is decomposed without residue by acid and heat.

TENAC™-C FF520 is a POM copolymer that provides very high fluidity while maintaining the excellent mechanical properties of POM.

As shown in the table below, TENAC™-C FF520 exhibits higher flowability compared to our conventional high-flow grade product. It’s available for your complicated and thin shapes.

POM undergoes depolymerization due to thermal decomposition and there is no residue.

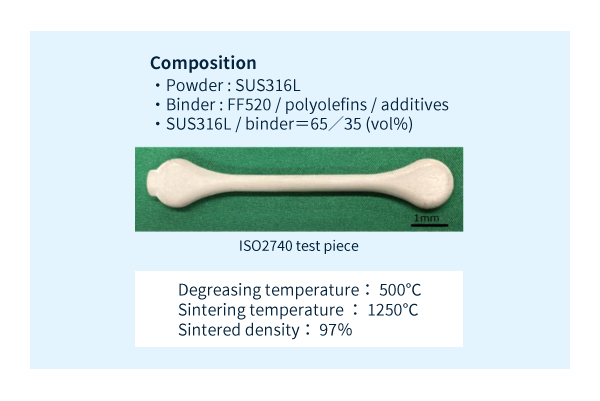

Molded products using

TENAC™-C FF520 can be degreased and sintered to obtain densely sintered products without cracking or blistering.

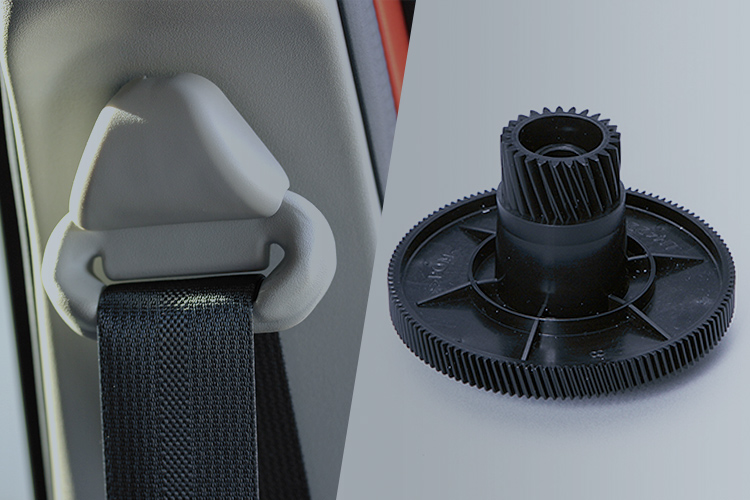

Powder Injection Molding (PIM) is a method of manufacturing small, high-precision metal and ceramic parts by injection molding metal or ceramic powder.

Specifically, metal or ceramic powder and binder are mixed and pelletized into feedstock, which is then injection molded.

:

:

Binder for thermal debinding

PT220 (pellet type)

By using our product-based binders for mixing with metal or ceramic powders, we can offer the following advantages over existing feedstocks

Please contact us to ask any questions, discuss any concerns, and request samples.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.