Solutions

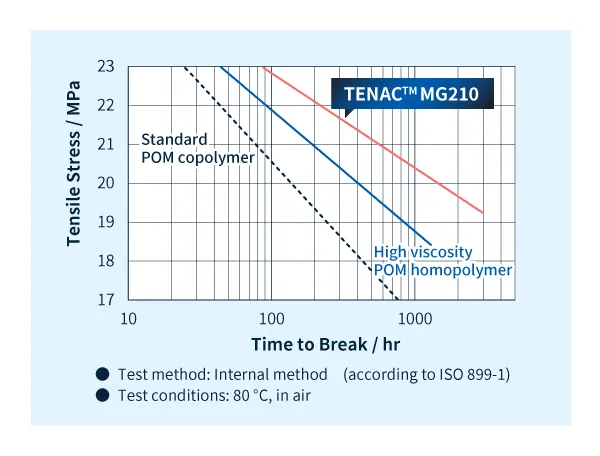

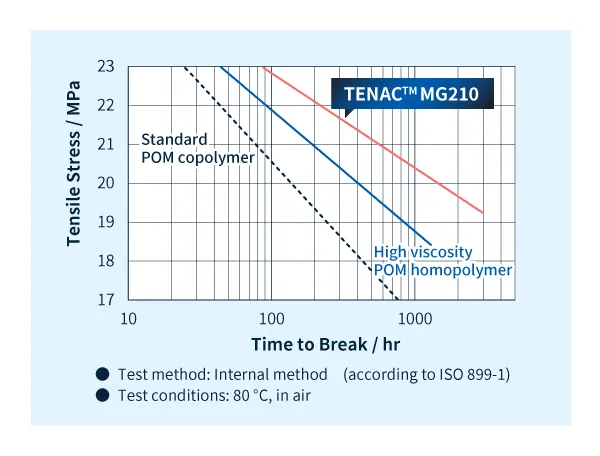

Creep Resistance

Compared to conventional POM,TENAC™ MG210 has been greatly improved creep resistance, making it suitable for applications where loads are applied for a long period of time.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

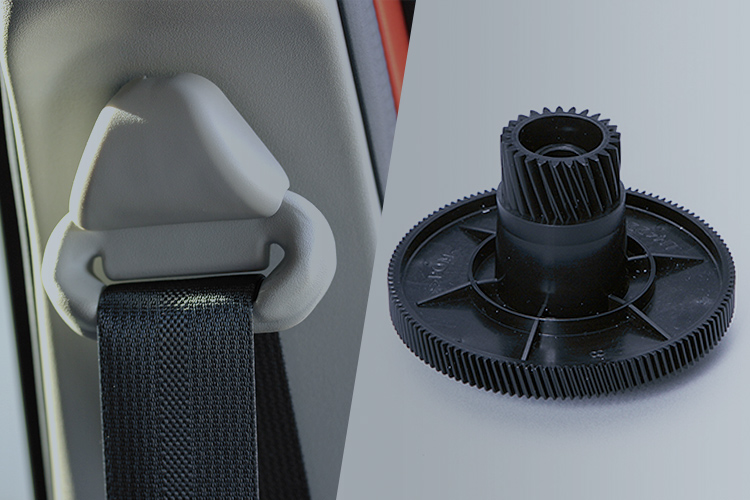

TENAC™ MG210 features improved durability, such as creep resistance and fatigue properties, of POM homopolymer. Due to its strength and durability, TENAC™ MG210 contributes to the miniaturizationof part size and weight reduction by substituting metal and reducing the number of parts.

TENAC™ MG210 has been widely used in gear applications where strength and durability are required.

While there is a concern fiber-reinforced resin may reduce strength and dimensional accuracy,

TENAC™ MG210 is a non-reinforced POM which has fewer concerns and can demonstrate the necessary strength and durability.

Compared to conventional POM,TENAC™ MG210 has been greatly improved creep resistance, making it suitable for applications where loads are applied for a long period of time.

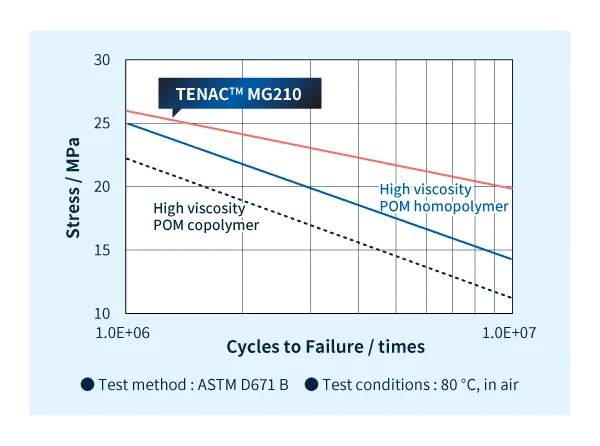

Compared to conventional POM, TENAC™ MG210 has been greatly improved flexural fatigue resistance, contributing to miniaturization of parts and improvement of product life.

Door rollers used to open and close sashes, cabinets, etc. smoothly.

A part that is constantly loaded and slides against metal.

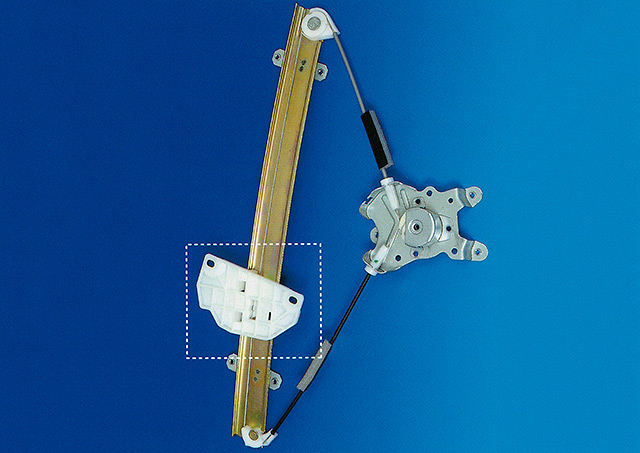

Window regulators, which are window glass lifting and lowering devices, and carrier plates that support window glass.

The repeated fatigue characteristics, creep resistance, etc. are required to continue to support the window glass.

Gears used in motors that drive doors, wipers, seats, etc.

They are subject to heavy loads and require durability and creep resistance.

Solutions

Please contact us to ask any questions, discuss any concerns, and request samples.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.