Precautions for handling TENAC™

The content of this document is based on currently available materials, information and data, and may be revised based on new findings. Please note that these are provided as information and are not guaranteed. Therefore, when using our products, please give full consideration to the usage environment, design, etc., and use them at your own risk after judging that there is no problem with the product.

1. Handling Precautions

Please read the separate "Material Safety Data Sheet" for handling precautions for TENAC™ before using TENAC™. The following points are the main points for handling TENAC™. Please use it for safe handling of TENAC™. Please investigate the safety and compatibility with TENAC™ ™ of pigments, additives, etc. that you use other than those specified by Asahi Kasei TENAC™.

(1) Safety and health precautions

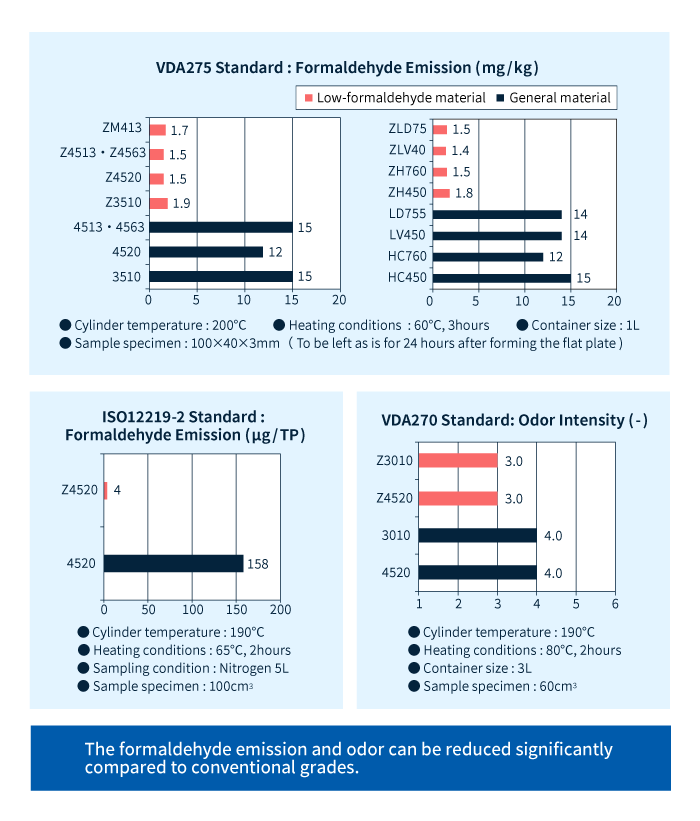

The main component of the gas generated when TENAC™ is dried, melted, and decomposed is formaldehyde. Take care to avoid contact with eyes, skin, and inhalation. Also, avoid touching the high temperature resin directly. For each work such as drying and melting, it is necessary to install a local exhaust system and wear protective equipment (safety glasses, protective gloves, etc.).

(2) Precautions regarding combustion

TENAC™ is flammable and should be handled and stored away from heat and sources of ignition. If it burns, it may generate toxic gas. Water, foam, and dry powder can be used to extinguish the fire.

(3) Precautions for disposal

TENAC™ can be disposed of by landfill or incineration, but please entrust it to an authorized industrial waste disposal company or local government in accordance with the "Waste Disposal and Public Cleansing Act." In addition, when incinerating it yourself, please use incineration equipment and process in accordance with various laws and regulations such as the Air Pollution Control Act. When incinerated, toxic gas may be generated.

(4) Notes on storage

It is a combustible material (synthetic resins) designated by the Fire Service Act, and should be handled in accordance with municipal ordinances. (fire extinguishing equipment, indoor storage facilities, etc.)

(5) Notes on molding

Please pay attention to the following points to avoid decomposition of the resin.・Do not allow the resin to remain in the processing machine for a long time at high temperatures.・Do not mix extrusion with strong acids, oxidizing agents, or PVC. Pellets, etc. spilled on the floor may slip under your feet and cause a fall if left unattended, so please clean and remove them immediately.

2. Usage

- ・Do not use TENAC™ for implantation into the body or for direct contact with body fluids or infusions. When using this product for other medical purposes, please be sure to contact our representative in advance.

- ・When using TENAC™ in applications where it comes into direct contact with food, please select a grade that complies with the Polyhyeikyo PL (Positive List), Food Sanitation Law, and FDA. In that case, please be sure to contact our representative in advance.

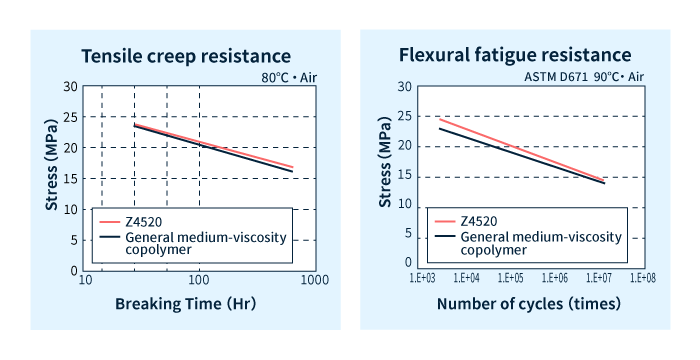

- ・When using TENAC™, be sure to evaluate the physical properties, durability etc. of the actual product in advance.

3. Others

Please be aware of industrial property rights, etc. when using this product.