Thermylene® R

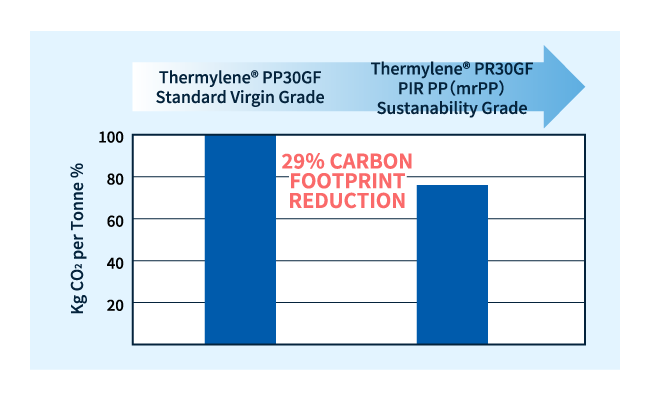

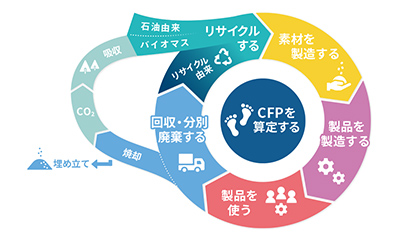

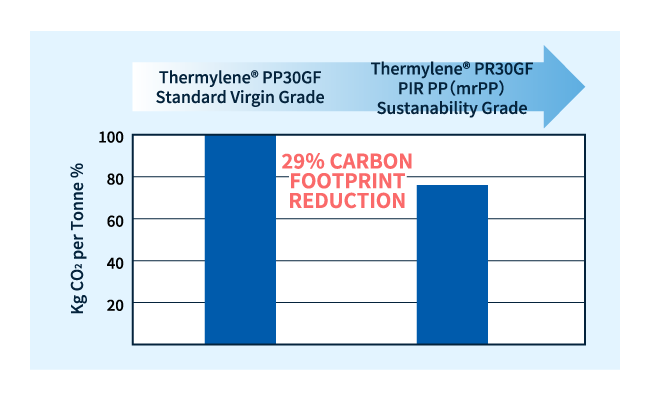

Thermylene® R represents the recycled grade series of Thermylene®, combining sustainability with superior performance. This product line boasts low density, a low carbon footprint, and excellent chemical resistance while maintaining superior strength. Thermylene® R is the ideal solution for applications requiring robust performance with an emphasis on environmental responsibility.

Thermylene® SoForm™

Soform™ is developed as a soft-touch haptics grade that provides structural soundness. It is tailored for weathering and enhanced scratch resistance in your applications. Soform™ can help eliminate the need for soft-touch paints and over-molding with soft materials while also being able to be directly injection molded.

Thermylene® Element™

Element™ is designed to provide your applications with a hydrophobic part surface to help repel ice and water build-up in cold conditions. Element™ can also help repel surface stains such as coffee, sunscreen, juice, and lotion to help your application have a stain-free and longer service life. It can be designed with tailored mechanical properties, weathering, and scratch resistance.

Thermylene® Stress Whitening Prevention™ (SWP)

The Thermylene® Stress Whitening Prevention™ (SWP) is a patented technology that eliminates stress whitening defects in molded applications. This technology was initially designed for furniture and consumer applications but has also been perfected to improve aesthetics in automotive interiors. SWP is available in various configurations to meet the mechanical requirements of various applications.

Thermylene® Thermoforming Grades

The Thermylene® Stress Whitening Prevention™ (SWP) is a patented technology that eliminates stress whitening defects in molded applications. This technology was initially designed for furniture and consumer applications but has also been perfected to improve aesthetics in automotive interiors. SWP is available in various configurations to meet the mechanical requirements of various applications.

Thermylene® TPO Grades

Thermylene®’s TPO grades are specialty compounded products available in various reinforcements and stiffness-toughness performance spectrums. They deliver critical attributes necessary for interior as well as exterior applications like high ductility performance at cold temperatures, high flow for thin-wall molding, excellent scratch resistance, acceptable gloss and aesthetics, and superior weathering resistance.

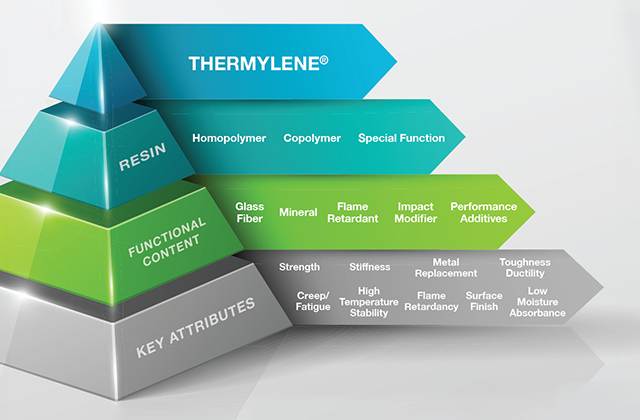

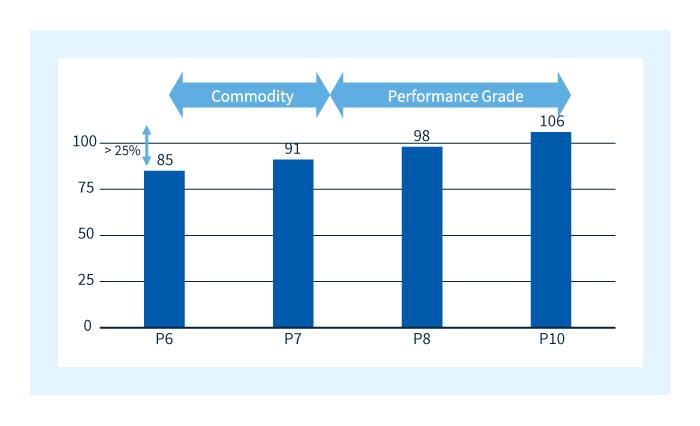

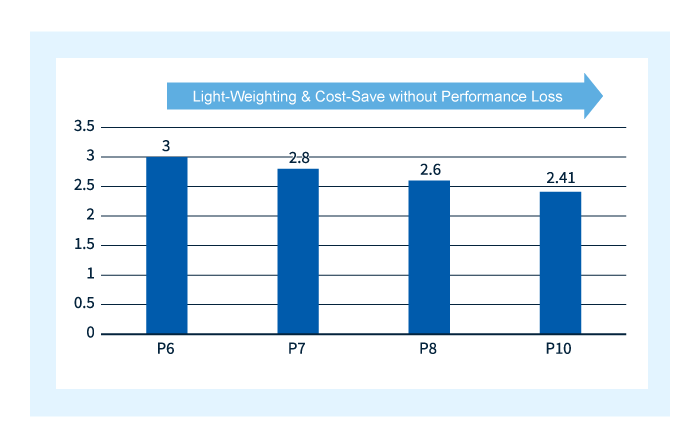

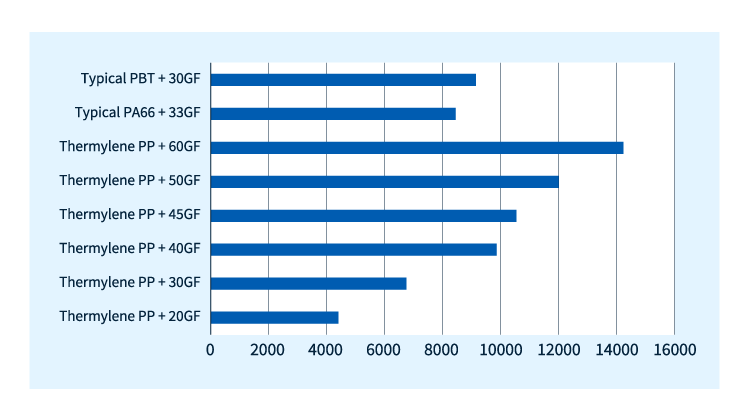

Thermylene® Glass Filled Grades

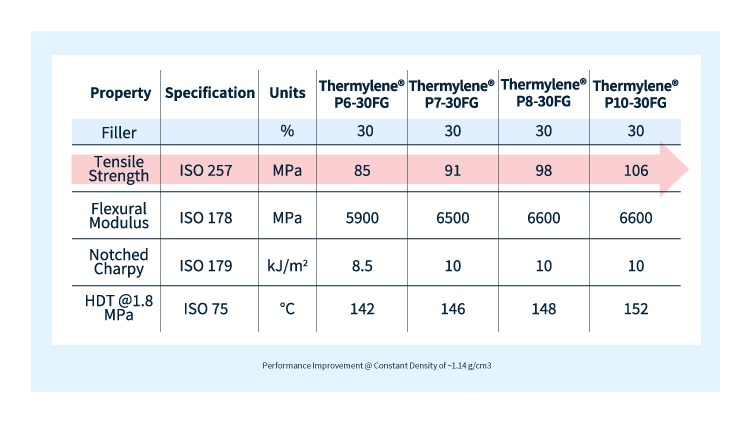

Glass fiber (GF) is the most widely used reinforcement in polypropylene (PP)-based composites as it provides a valuable balance between costs and properties. Glass-fiber-reinforced polypropylene compounds (PPGF Plastic) deliver improved strength, structural rigidity and dimensional stability in applications.

The key performance in glass-reinforced polypropylene compounds is delivered by the efficacy of formulation design and polymer fiber interphase. Thermylene® products provide increased durability, strength and stiffness for critical structural components. Polypropylene compounds that are long glass fiber reinforced have significantly improved flexural modulus and tensile strength because of superior design and state-of-the-art production technologies applied by Asahi Kasei.