High Strength, Stiffness, and Performance

PA 66 and PA 6

What is Thermylon®?

Thermylon® is a premier line of engineering plastics from Asahi Kasei Plastics North America, designed to meet the rigorous demands of high-temperature and structural applications. Comprised of advanced polyamide materials, including PA 66 and PA 6, Thermylon® delivers exceptional performance across various industries. With versatile filler options such as glass fiber, mineral, or unreinforced, Thermylon® is engineered to provide the specific characteristics and resistance required for challenging environments.

What is Thermylon® R?

Thermylon® R, the recycled grade series of Thermylon®, exemplifies Asahi Kasei Plastic North America's dedication to sustainability and high performance. This series is engineered with diverse feedstreams, including Post-Industrial Recycled (PIR) options. Thermylon® R offers superior strength and high stiffness, making it ideal for demanding applications such as metal replacement and high-temperature environments. It is designed to lower carbon footprint while maintaining the robust performance required for industrial and consumer applications. Asahi Kasei provides comprehensive design-to-launch support, enabling the successful implementation of Thermylon® R in your sustainable projects.

Application cases

- Application Segments

- Thermylon® is the material of choice for various applications, particularly where high strength, stiffness, and resistance to various elements are crucial. Its diverse range of variants makes it suitable for:

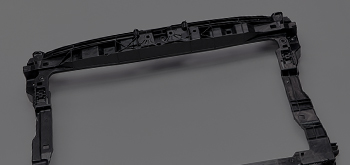

- Automotive Components: Ideal for parts that require high heat resistance and durability, such as engine covers, underhood components, and structural elements.

- Industrial Machinery: Used in mechanical parts that endure heavy loads and friction.

- Consumer Goods: Applied in products needing high performance and longevity, such as power tools and sports equipment.

- Furniture: Ideal for furniture components requiring strength, durability, and resistance to wear and tear, enhancing both performance and aesthetics.

- Metal Replacement: Provides a lightweight yet strong alternative to metal components, improving efficiency and reducing costs.

- Safety and Flame Resistance Applications: Essential for components in environments where ignition resistance and flame retardancy are critical, such as electrical housings and safety equipment.

Processing Guides and Testing Documents

Processing Guide

Knowing the safe and proper technique for processing our high-performance plastic compounds is vital. Our guides will give you an understanding of the following:

- Correct handling

- Target melt temperature

- Barrel heat recommendations

- Suggested screw design

- Shrinkage rates and mold temperatures

- Fill pressure

- Venting recommendations

Are you interested in Thermylon®?

Connect with us to discuss your next project with one of our team members.

- Asahi Asahi Kasei engineering plastics' contribution to achieving carbon neutrality

- The Asahi Kasei Group is committed to contributing to the realization of a carbon neutrality, sustainable society.

We will introduce our efforts to achieve a circular economy in the engineering plastics business. -

Learn more