“Asahi Kasei Europe Battery Project”

Interviews

NEW SERVICE!

CAE ServicesFor inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

Bonding over design headaches: Building a trusted partnership through trial and error

2022.12.25

Interviews

The vision statement of Asahi Kasei’s medium-term corporate mission is Contributing to safe, comfortable, and sustainable next-generation mobility —and the automobile industry is among the most important strategic arenas for this initiative. Of course, Asahi Kasei already boasts a decades-long track record as a supplier of high-performance engineering plastics and other advanced materials to manufacturers of vehicles and vehicle components. However, in recent years we have launched a number of initiatives in which we not only supply materials to component manufacturers, but also collaborate directly with those manufacturers—as well as manufacturers of end-stage products—to develop innovative new components capable of taking full advantage of our unique materials and technologies.

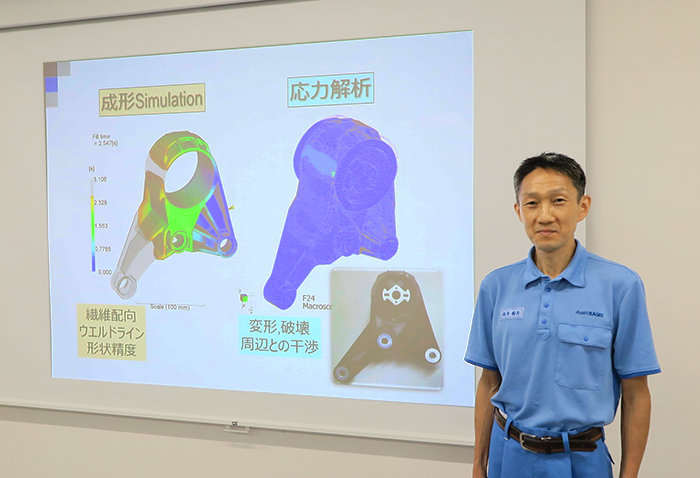

Engineer Mikio Sakamoto was stationed at Asahi Kasei Plastics (Shanghai) Co., Ltd.

Engineer Mikio Sakamoto was stationed at Asahi Kasei Plastics (Shanghai) Co., Ltd.

“Although this was a joint-development project with Nobo, unfortunately it did not continue all the way to a final stage involving mass-produced components,” explains Sakamoto. “Nonetheless, from our perspective at Asahi Kasei, it seemed clear that the various challenges that arose could lead to some enormous opportunities down the road.

“Until recently I was stationed at the Shanghai Technology Center,” says Sakamoto, “and getting from there to Nobo’s offices in Baoding was quite a journey. We would set out from Shanghai one day in advance, spend the night in Tianjing, and then travel the rest of the way by high-speed train and taxi the next morning. By the time our meetings at Nobo finished up, I wouldn’t get home to Shanghai until late at night.”

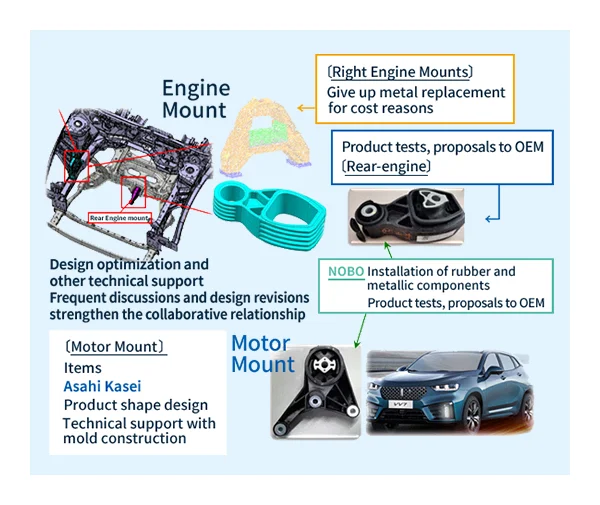

Nobo—a top-tier player in China, supplying components primarily to the large Chinese automakers—had been actively exploring design strategies to replace metal components with resin components, both to enhance the value and reduce the weight of automotive components. Asahi Kasei was able to make a wide range of suggestions to help advance this effort.

“Our involvement in this project went far beyond the usual role of a material vendor,” Sakamoto recalls. “We didn’t just supply materials. We didn’t just respond narrowly to the customer’s specific questions and call it a day. Instead, we went out of our way to answer every one of Nobo’s questions—about materials, and about everything else—as thoroughly as we could. We put our heads together with Nobo engineers to work through design problems. I think we really established a tight working relationship with Nobo’s team, and I like to think we earned their trust as a partner they can really count on.”

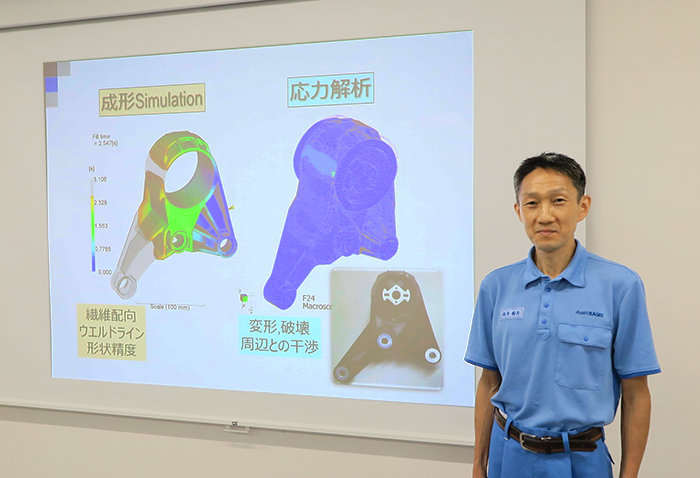

Sakamoto recalls how the design collaboration got started. “What happened was, Nobo reached out to us to discuss the design of engine and motor mounts—the fixtures used to install engines and motors in vehicles—and we helped them out. They were interested in replacing aluminum die-cast mounts with mounts made from resin materials to reduce cost and weight. But this is no easy task, because mounts are required to meet demanding performance specifications; not only must they provide a staunch base of support to keep engines and motors—extremely heavy subsystems—fixed firmly in place, but they must also incorporate rubber components to attenuate vibrations. In this case we wound up designing both engine and motor mounts, although their basic structures and functionality were similar.”

▲ Overview of design process for resin mounts

▲ Overview of design process for resin mounts

“This project formally began in 2019,” Sakamoto explains, “but in fact back in 2013 we had already tackled the metal replacement of engine mounts. In that case, some issues emerged just before we were to start mass production, and unfortunately Nobo and we wound up needing to cancel our plans to commercialize Nobo’s product. But by 2019 there had been a change in management both on our side and on Nobo’s, and we figured ‘why not give it one more try—and get it right this time!’

Given the history, Nobo’s attitude this time around was cautious: Are you guys sure it’s going to work this time? But at Asahi Kasei, we were enthusiastic: we saw an opportunity to achieve something that had never been done before—and which promised to yield extremely high-value dividends—and we were hopeful that Nobo would be willing to work with us to make it a reality. So the original proposal for a joint-development project came from our side: Asahi Kasei suggested it, and Nobo graciously agreed.

In a typical development cycle, we would have no choice but to await—and defer to—the customer’s decisions on everything from constructing molds to ramping up mass-production. But this project was different: we told Nobo that we’d provide technical support in areas such as designing product shapes and constructing molds, and we encouraged them to let us furnish them with everything they needed, right up to preparation for mass production. In return, we asked Nobo to design and experimentally test the rubber vibration-isolation components; they did this and shared the results with us, and this division of labor helped to accelerate the overall design process.”

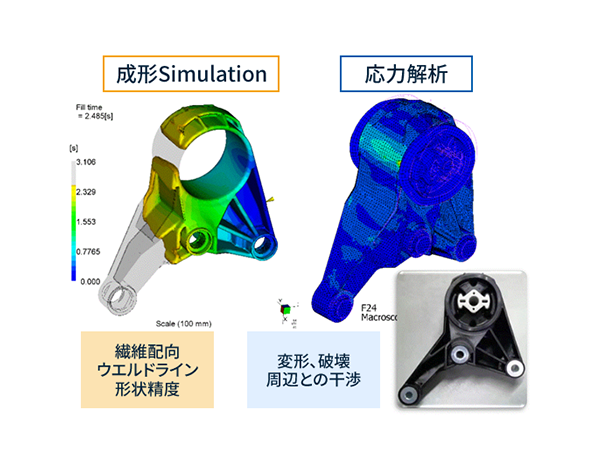

The resin material selected for this mount was Asahi Kasei’s LEONA™ 14G50, a glass-fiber-reinforced grade of our nylon (polyamide) 66 featuring good heat resistance, good fatigue resistance, and high strength and rigidity. After a design-optimization process to determine the optimal product shape based on rigidity and strength requirements, Sakamoto’s team conducted CAE (Computer Aided Engineering) simulations to determine weld lines and the orientation of glass-fiber, and then used this information to perform stress analyses to characterize the mechanical performance. By the end of this process, Sakamoto and his colleagues were confident that they had zeroed in on the optimal shape needed to take full advantage of the unique properties of LEONA™ resins—including questions of processability and other considerations relevant for mass production.

▲ Result of the design collaboration: motor mount made entirely from resin materials

▲ Result of the design collaboration: motor mount made entirely from resin materials

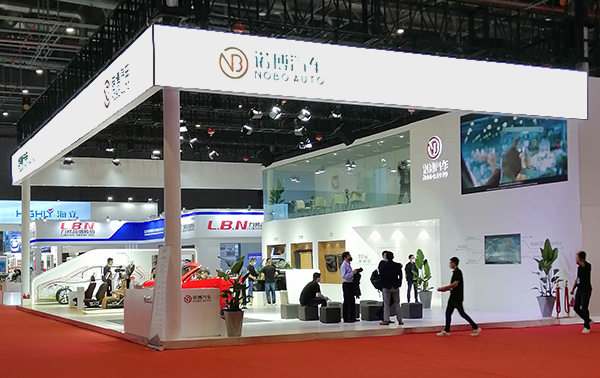

▲ Nobo booth at Shanghai Motor Show

▲ Nobo booth at Shanghai Motor Show

▲ Resin mounts on display at Nobo booth at Shanghai Motor Show

▲ Resin mounts on display at Nobo booth at Shanghai Motor Show

Sakamoto describes the next steps in the collaboration. “We got as far as building a prototype mold and producing some prototype resin mounts, complete with rubber and metal components installed, which we exhibited at the Shanghai Motor Show.

However, just then the OEM announced a major change in performance requirements. Basically, for some reason, the OEM chose that exact moment to make the loading conditions significantly more stringent. We never did get a clear explanation of why this happened, but we started trying to design improved shapes—to the extent that we were able to modify the mold—and playing around with molding conditions, with Nobo conducting a steady stream of product tests. The result of this was that somehow or other we managed to pass tests for the mounts on their own, and we were ready to move on to the next stage: tests of mounts installed in vehicles, conducted by the OEM. However, from some time before there had been a flurry of changes in specifications from the OEM, and—although we and Nobo did everything we could to comply with the new requirements—eventually it became clear we wouldn’t finish our work before the new vehicle models went on sale, so ultimately there was no choice but to go back to the original metal mounts for mass production.

Of course, there remained the possibility of switching to resin mounts at some future point when minor change model would be launched. However, it’s difficult to make major changes in products that have already started to ship, and at the end of the day we weren’t able to get the OEM to adopt the new resin mounts we had designed.

I think another factor that contributed to this unfortunate outcome was COVID-19. I was in charge of the engineering work, and if I had been able to visit the OEM directly and explain the situation to them, things might have turned out a little differently.

But all of this was happening at a time when, in mainland China, travel between cities would be shut down at the slightest hint of a COVID outbreak. So it was essentially impossible to travel the significant distance from Shanghai to Baoding, and I wasn’t able to visit people to discuss things in person. The sales team at Asahi Kasei’s Tianjin office did everything they could to keep in touch with Nobo and facilitate negotiations with the OEM, but ultimately this was just a time when communicating effectively was very difficult.”

Sakamoto remembers how the technical manager of Nobo’s team expressed regret over the situation. “He said, ‘I hate to disappoint you guys after all the effort you’ve put into helping us with this project…I wish things had gone differently. But once a product has started to ship, it’s very difficult to switch from metals to resins.’

But he had other opportunities in mind: ‘We hope you’ll work with us again in the future, because we plan to propose some new products that will be resin-based from the start.’ They said they wanted to prepare some technical material regarding resin mounts to present to the OEM as a demonstration of enthusiasm and of thorough planning, and we were able to help them with that.

After that, we had hoped that all three companies—Asahi Kasei, Nobo, and the OEM—could get together for discussions, but I wound up returning to Japan before that ever happened.

Nobo is a valued customer with a long history of choosing Asahi Kasei materials. Although this particular project didn’t lead to any specific achievements for Asahi Kasei, it helped to strengthen ties and deepen our relationship with Nobo, which I see as a very positive outcome.

In the past, we relied on our sales associates to communicate proposals to Nobo, and frankly they never took our suggestions very seriously—it was always like ‘We’re very busy and have no time for you today.’ But in this case we had our engineers explaining everything very thoroughly, and this brought Nobo enthusiastically on board—they were prioritizing meetings with us, all the way up to the head of their engineering department in charge of development.

It’s a shame that our collaboration didn’t bear fruit this time, but nobody at Asahi Kasei criticized us for this—indeed, quite the opposite: already we’ve identified multiple ways to pursue resin-mount development projects with other customers, and everybody realizes these opportunities were made possible by our work with Nobo.

We’re really looking forward to working again with Nobo on the next joint-development challenge—and getting the OEM to adopt our designs this time!

▲ Two members of Asahi Kasei’s team in China who were involved in collaboration with Nobo: Feng Jian from the Sales & Marketing,Engineering Plastics for Automotive (Tianjin office) (left) and Jin Jie from the Market Development Group (right).

▲ Two members of Asahi Kasei’s team in China who were involved in collaboration with Nobo: Feng Jian from the Sales & Marketing,Engineering Plastics for Automotive (Tianjin office) (left) and Jin Jie from the Market Development Group (right).

Jian Feng works with the Engineering Plastics for Automotive Group to support OEM and Tier-1 customers in the Tianjin region. He organized many discussions and negotiations with Nobo, helping to build trust in the partnership.

Jin Jie works with the Market Development Group and oversees Asahi Kasei’s efforts to offer technical support and technical proposals to customers throughout China. For the Nobo project he served as a LEONA™ materials engineer, with primary responsibilities including offering technical support for material properties and formation, selecting a mold manufacturer, overseeing mold construction and prototype production, and listening carefully to feedback from customers to facilitate solutions to problems.

Feng Jian and Jin Jie share their thoughts

Every proposal for replacing metal components with resin equivalents requires multiple cycles of shape redesign and performance testing—it’s a lengthy process, which doesn’t always go the way you expect. But it’s important not to give up easily: you have to keep trying, stubbornly, over and over again until the design is perfected. Also, fabricating something such as an automotive component and getting it properly tested requires a very solid relationship with the customer. So we’re happy to be in a position to assist Asahi Kasei to improve the technology it provides and help solve problems like making electric vehicles more comfortable and lighter in weight.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.