Technologies and Products

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

PRESS RELEASE

2022.12.14

Press Releases

December 14, 2022

Asahi Kasei Corporation

Asahi Kasei has developed basic technology for recycling continuous carbon fiber under a project “Circular Economy Program for the Automotive Carbon Fiber” (the Project), together with National Institute of Technology, Kitakyushu College, and Tokyo University of Science, which was supported by the Feasibility Study Program on Energy and New Environmental Technology, of the New Energy and Industrial Technology Development Organization (NEDO) from fiscal 2021 to 2022.

The Project was adopted in May 2021 by the NEDO Feasibility Study Program on Energy and New Environmental Technology, which aims to discover technology seeds needed for medium- to long-term solutions in the field of energy and the environment, including energy conservation, new energy, and CO2 reduction, that are unlike existing technologies and can be applied in future national projects contributing to dramatically increased energy efficiency and achievement of a low-carbon society.

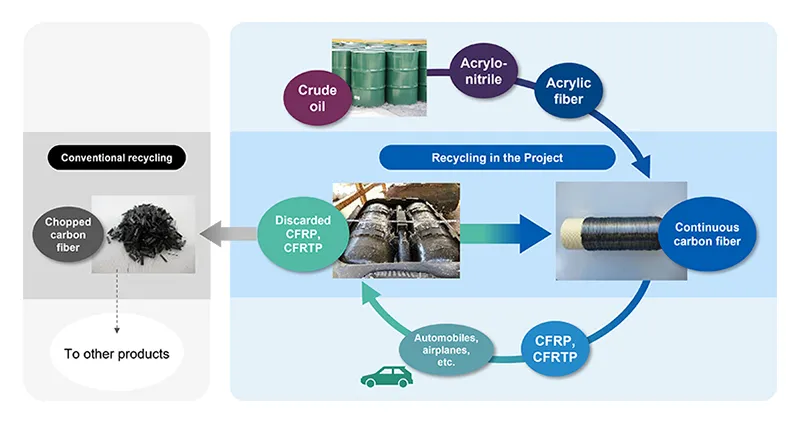

The Project, aims for practical application of a recycling system where carbon fiber derived from carbon fiber reinforced plastic (CFRP) or carbon fiber reinforced thermoplastic (CFRTP) discarded from automobiles is reused as CFRP or CFRTP for automobiles. By recycling carbon fiber discarded from automobiles as continuous carbon fiber, high-quality and inexpensive CFRTP can be provided, resulting in vehicle weight reduction and energy saving. This is also expected to economically benefit and strengthen the competitiveness of Japan’s leading carbon fiber and automobile industries.

The conventional recycling technology recycles carbon fiber as chopped carbon fiber※1. However, as chopped carbon fiber differs greatly from original continuous carbon fiber, it was necessary to develop individual composite technology. In contrast, the Project enables continuous carbon fiber recycling, allowing existing composite technology to be used, making it possible to achieve closed-loop recycling※2 of the circular economy.

Characteristics of the Project

Characteristics of the Project

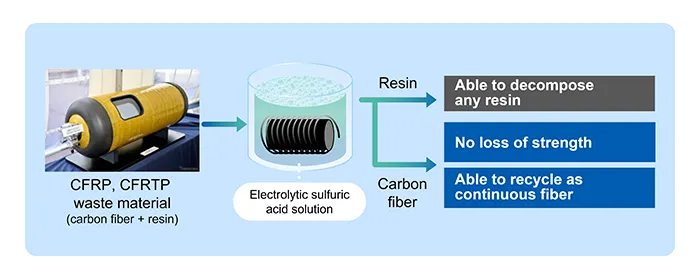

An “electrolyzed sulfuric acid method” was developed for the Project. The “electrolyzed sulfuric acid method” is a technology that uses oxidative active species※3 generated by electrolyzing sulfuric acid to decompose the resin components of CFRP/CFRTP and extract and recycle carbon fibers. This technology has three features: (1) it can decompose any kind of resin, (2) strength of the recycled carbon fiber does not decrease, and (3) carbon fiber can be recycled as continuous fiber.

Electrolyzed sulfuric acid method

Electrolyzed sulfuric acid method

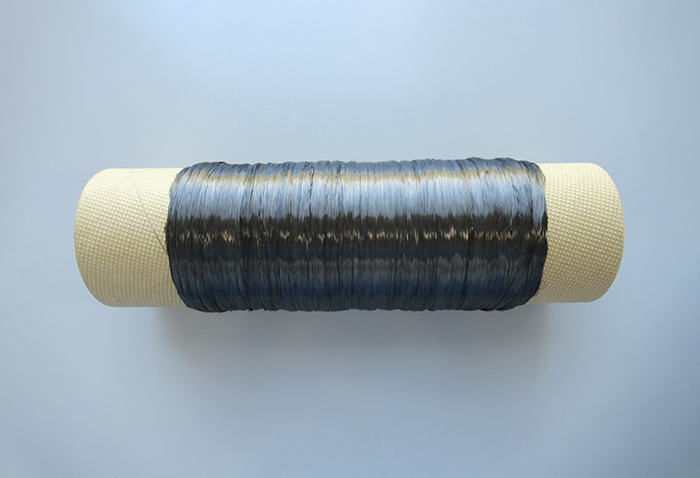

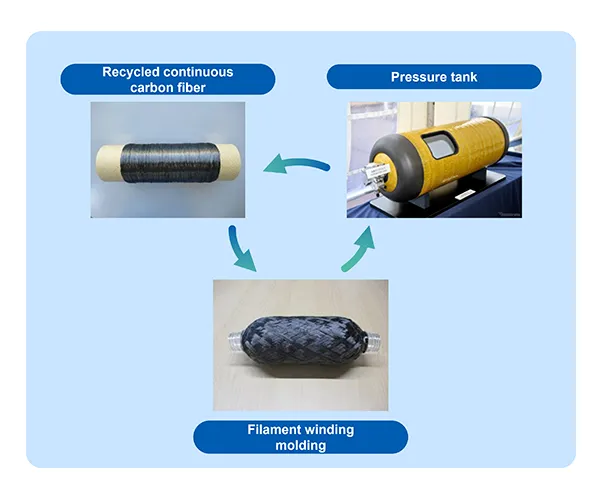

Basic technology was developed for recycling continuous carbon fiber from small commercially available CFRP tanks for scuba diving. The recycled continuous carbon fiber has no “twisting” or “fluffing” and can be handled in the same way as new carbon fiber. This enables a tank-to-tank circular economy through the repeated use of filament winding ※4.

Recycled continuous carbon fiber and filament winding molding

Recycled continuous carbon fiber and filament winding molding

Asahi Kasei is also developing CFRTP-UD tape (unidirectional tape, a unidirectional continuous fiber reinforced material) using the recycled continuous carbon fiber and LEONA™ polyamide resin. Having higher strength than metal, CFRTP-UD tape is expected to be applied to automobile frames and bodies, further enabling the recycling of automobile parts into other automobile parts.

→Developing Uni-directional Tape (UD-Tape): A carbon-fiber-reinforced polyamide resin

Moving forward, Asahi Kasei will perform demonstrations and develop the business, aiming for practical application around 2030.

CFRTP-UD tape using recycled continuous carbon fiber and LEONA™ polyamide resin

CFRTP-UD tape using recycled continuous carbon fiber and LEONA™ polyamide resin

The Asahi Kasei Group aims to contribute to a carbon-neutral and sustainable world from the perspective of “Care for Earth” by focusing on initiatives such as the use of biomass raw materials, recycled raw materials, and renewable energy. The company strives to meet the expectations of its customers and society by further advancing the provision of products and services with such sustainable characteristics while deepening collaboration with other companies based on its medium-term management plan for fiscal 2024 focused on the theme “Be a Trailblazer.”

※1 Carbon fiber processed products with carbon fiber chopped into lengths of 3 to 24 mm

※2 A manufacturing process by which a product or material can be used and then turned into a new product without losing its properties during the recycling process.

※3 A substance that is highly oxidative and can decompose resin.

※4 A molding method in which rovings (continuous fiber bundles) are aligned and continuously wound at a predetermined angle around a rotating mold while being impregnated with resin.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.