“Asahi Kasei Europe Battery Project”

Interviews

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

~A solution for the future beyond 5G~

2023.06.23

Technologies and Products

Asahi Kasei Corporation (Headquarters: Chiyoda-ku, Tokyo; President: Koshiro Kudo) and the Hirokawa Laboratory at Tokyo Institute of Technology (TIT)’s School of Engineering have embarked on a joint research project to make gap waveguide slot array antennas from resin instead of metal, in anticipation of future utilization as wireless communication goes beyond 5G.

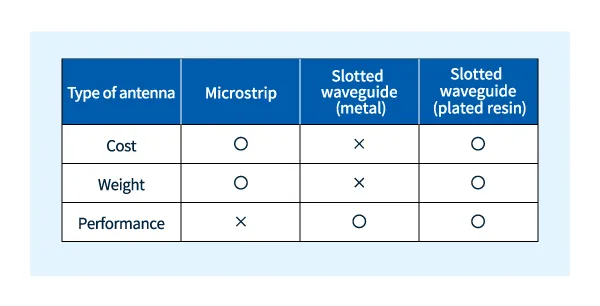

The use of millimeter waves has been promoted in recent years to keep up with the ever faster speed and larger capacity of wireless communication. However, when manufacturing millimeter waveband antennas, manufacturers have come up against issues such as machining limitations and material loss. Gap waveguide slot array antennas are being developed to comprehensively address these problems. A gap waveguide slot array antenna consists of a large number of slotted antenna elements in a metal waveguide, which acts as an array antenna. Compared to a microstrip array antenna*, slotted waveguide array antennas offer higher performance in the millimeter waveband, but they are heavy and expensive to manufacture. These issues have limited their use in civilian applications, and they are mainly used in satellite and military applications. Recently, due to the high performance of slotted waveguide array antennas, developers have considered applying them in drones, base station antennas, and ADAS (Advanced Driver-Assistance Systems), but the weight and cost issues have prevented them from being adopted. To address this challenge, Asahi Kasei and TIT are working on making waveguides from metal-plated XYRON™ modified PPE (modified polyphenylene ether or mPPE) in an attempt to keep the weight and manufacturing cost down.

Comparison of array antennas

Comparison of array antennas

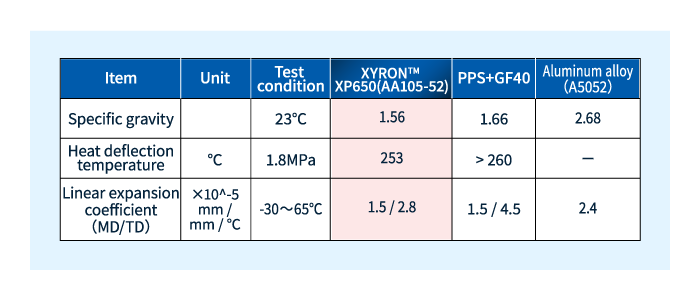

For the resin antenna prototype, XYRON™ XP650 (AA105-52) was used. In addition to high heat resistance, this grade achieves a stable low coefficient of linear expansion over a wide temperature range, making it suitable for resinifying metal parts that require precision, such as gap waveguide slot array antennas.

Physical properties

Physical properties

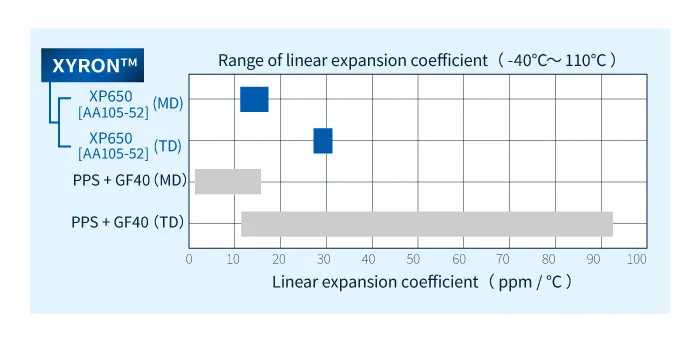

Linear expansion coefficient

Linear expansion coefficient

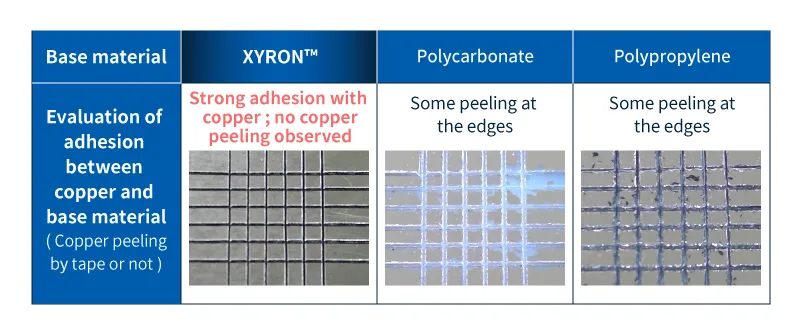

In addition, XYRON™ has excellent plating properties and adheres better to copper than other materials such as polycarbonate and polypropylene, as shown in the evaluation results below.

Evaluation of adhesion between copper and base material

Evaluation of adhesion between copper and base material

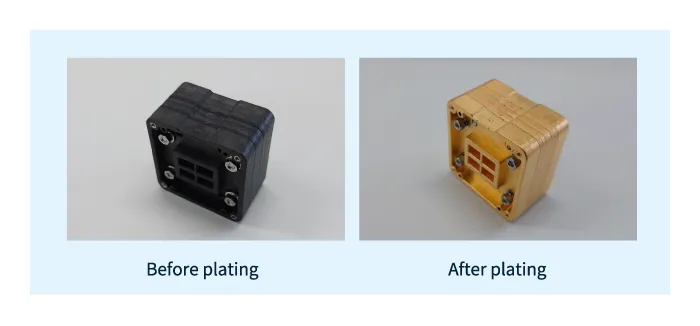

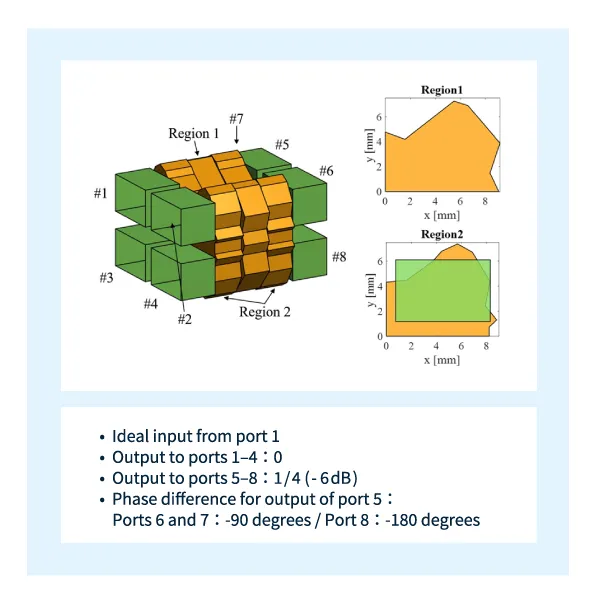

In the first stage of the project, the team created a resin antenna circuit with four 2×2 apertures on the input side and similarly four apertures on the output side, and conducted experiments to compare its performance with that of a metal antenna circuit (designed for the millimeter waveband).

Resin antenna circuit

Resin antenna circuit

Hybrid structure

Hybrid structure

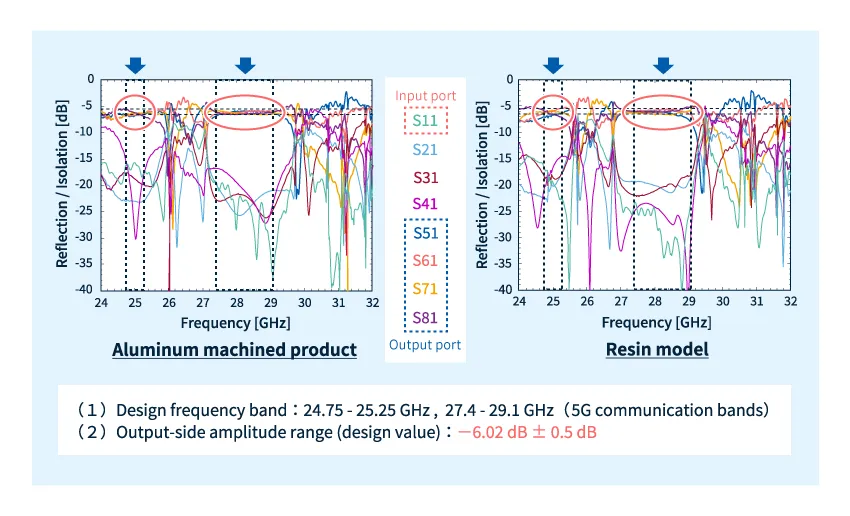

Even the slightest error will affect the circuit characteristics, so high dimensional accuracy and plating accuracy are required. The XYRON™ antenna circuit succeeded in solving these challenges. In terms of weight, the prototype is approximately 40% lighter than the metal antenna circuit. With regard to circuit characteristics, as shown by the comparison below, the output-side amplitude range was within the design value except in certain high-frequency bands, and the performance was equivalent to the aluminum machined product. The model produced good results, with reflection of -15 dB or less and low loss, confirming that it operated just as well as the metal antenna circuit.

(2023年6月開催「COMNEXT 第1回 次世代通信テクノロジー国際展」にて樹脂製アンテナの簡易モデルを出品しました)

Going forward, the team plans to produce prototypes on a larger scale and conduct experiments with a view to practical use.

Comparison of circuit characteristics

Comparison of circuit characteristics

※Microstrip array antenna: A flat antenna consisting of a dielectric substrate with radiating elements etched on the front and a ground plane on the back

Please contact us to ask any questions, discuss any concerns, and request samples.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.