Technologies and Products

NEW SERVICE!

CAE ServicesFor inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

2025.01.20

Technologies and Products

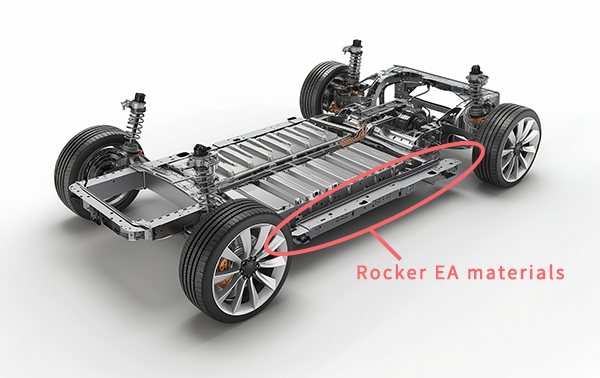

Rocker EA materials are hollow-bodied components, typically made from aluminum, installed on the side walls of battery packs in battery electric vehicles (BEVs). In the event of a side-impact collision, these components absorb energy by deforming into carefully-designed folded configurations, thus minimizing the impact force transferred to the battery.

Electric-vehicle batteries often span the entire underside of the vehicle chassis. Consequently, in the event of a side-impact collision, the need to ensure passenger safety is augmented by the need to prevent damage to the battery and secondary incidents such as fire or explosions—making rocker EA materials among the most important vehicle components.

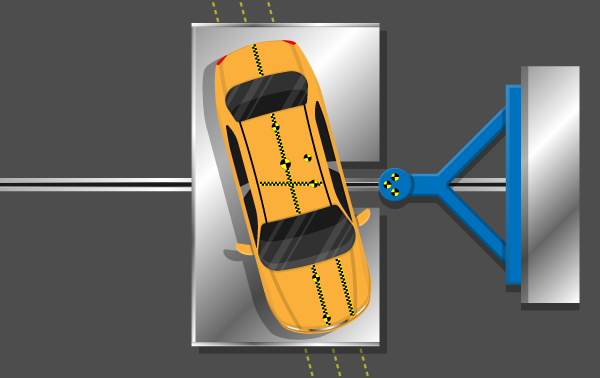

In developing rocker EA materials, the first key imperative is to ensure that the battery remains thoroughly protected in the event of a side-impact collision. In particular, the absorber must meet or exceed the “pole side-impact collision standard,” which requires that certain conditions be satisfied in the event of a side-impact collision between the vehicle and a rigid pillar resembling a utility pole.

Testing compliance with the pole side-impact collision standard

Testing compliance with the pole side-impact collision standard

At the same time, the goal of enabling longer travel distances requires BEVs to be equipped with more and more battery packs—while simultaneously keeping vehicles as lightweight as possible. Thus, increases in the size or weight of rocker EA materials are to be avoided whenever possible.

This creates a demand for novel materials that can effectively absorb collision energy while consuming only a limited amount of space—meeting the dual imperatives of meticulously protecting batteries while securing capacity for battery-pack installation.

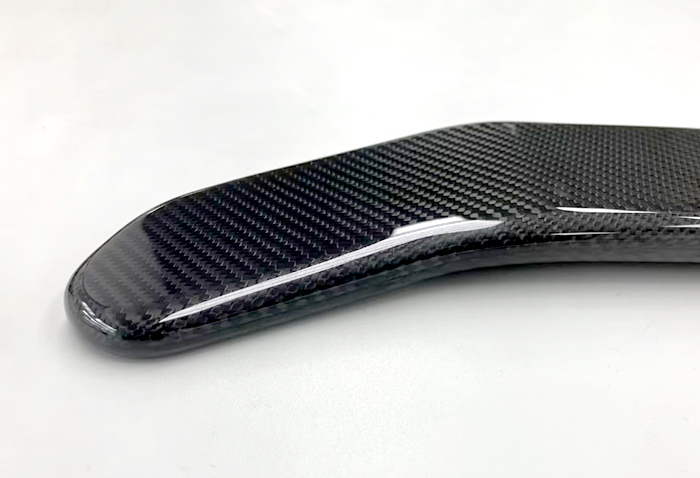

Asahi Kasei recommends our SunForce™ engineering plastic foam beads for use in rocker EA materials for BEVs.

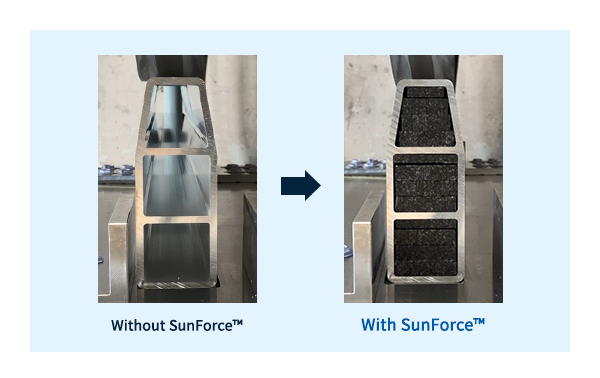

Conventional aluminum rocker EA materials have hollow bodies. Filling these hollow interiors with lightweight, high-strength SunForce™ components increases energy absorption—and thus helps to reduce component size and weight.

Cross-sectional image of a rocker energy absorber before and after filling the hollow interior with SunForce™ components.

Cross-sectional image of a rocker energy absorber before and after filling the hollow interior with SunForce™ components.

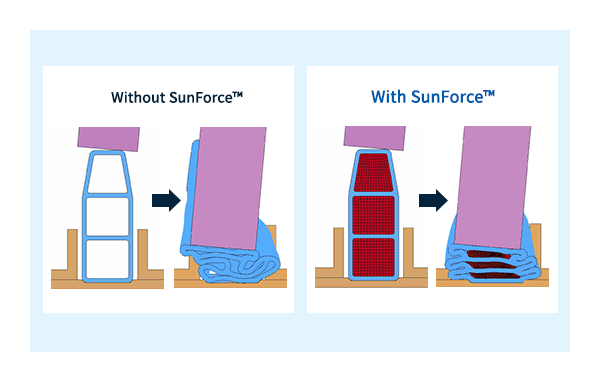

When the hollow interior of an aluminum rocker EA material is filled with SunForce™, the deformation of the aluminum and the compressive deformation of the SunForce™ allow an increase in overall energy absorption.

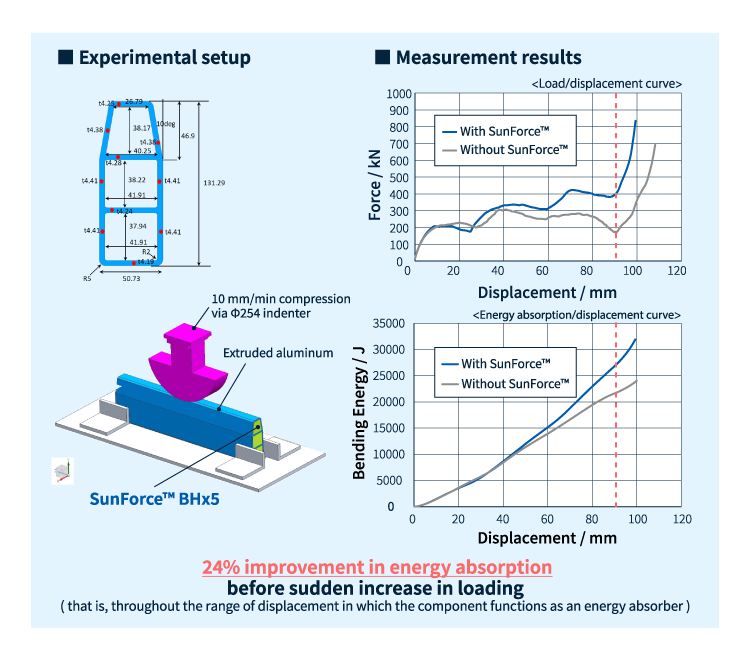

This effect has been confirmed and quantified by actual experiments: as we see in the figure below, filling with SunForce™ increases energy absorption by 24%.

Results of experimental tests to compare energy absorption (EA) before and after filling with SunForce™

Results of experimental tests to compare energy absorption (EA) before and after filling with SunForce™

Video: Comparison of energy absorption with and without SunForce™

These results demonstrate that rocker EA materials, despite their narrow width, are highly effective at absorbing the impact of collisions. This allows the overall size of the components to be reduced—thus freeing up precious design space—and also allows the aluminum components to be designed with thinner walls, reducing their weight. Because SunForce™ boast outstanding specific strength compared to other foam materials, their energy-absorbing performance is excellent, as is their heat resistance.

| Foam material | Energy absorption | Heat resistance |

|---|---|---|

| SunForce™ | ++ | ++ |

| Polystyrene foam | ++ | - |

| Polypropylene foam | - | ++ |

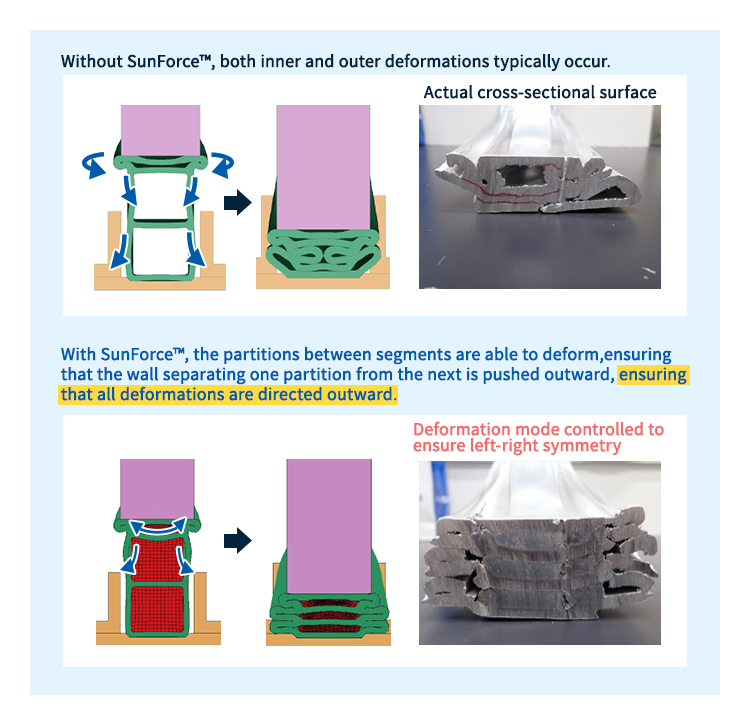

As shown in the figure below, filling aluminum rocker EA materials with SunForce™ beads allows the deformation mode induced by collisions (the precise way in which the rocker folds and deforms in the event of a collision) to be controlled.

Filling rocker EA materials with SunForce™ allows their deformation mode to be controlled.

Filling rocker EA materials with SunForce™ allows their deformation mode to be controlled.

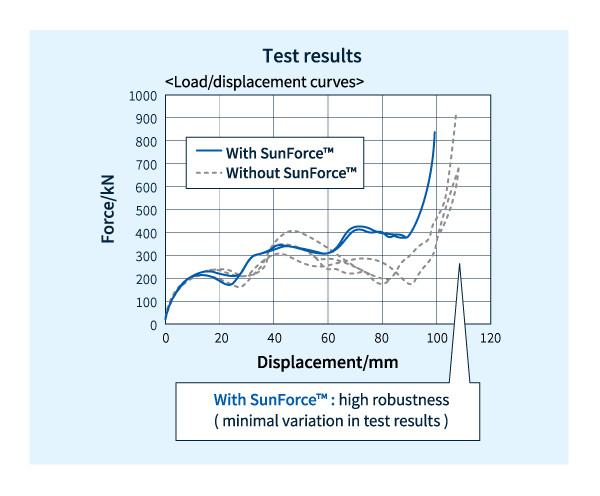

As shown in the figure below, this control over deformation modes reduces the variation in energy absorption during collisions, as required by the pole side-impact collision standard—thus enabling the development of highly reproducible material components.

Comparing robustness with and without SunForce™

Comparing robustness with and without SunForce™

The high robustness afforded by deformation-mode control also ensures effective energy absorption in cases where the impact force during a collision is not necessarily in the perpendicular direction, but at an inclined angle.

Non-perpendicular collision force

Non-perpendicular collision force

These advantages ensure that rocker EA materials filled with SunForce™ offer effective impact absorption while reducing space and weight requirements, helping to make BEVs safer and more functional.

If you are interested, please contact us.

Please contact us to ask any questions, discuss any concerns, and request samples.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.