Product

Excellent flame retardancy, electrical properties, dimensional stability, and water resistance. It is used in photovoltaics, batteries, and communication components.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

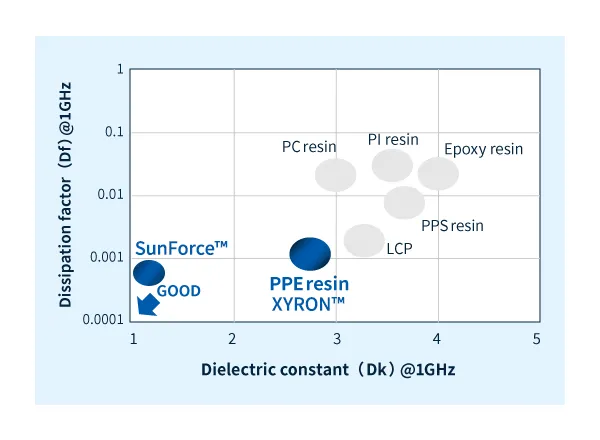

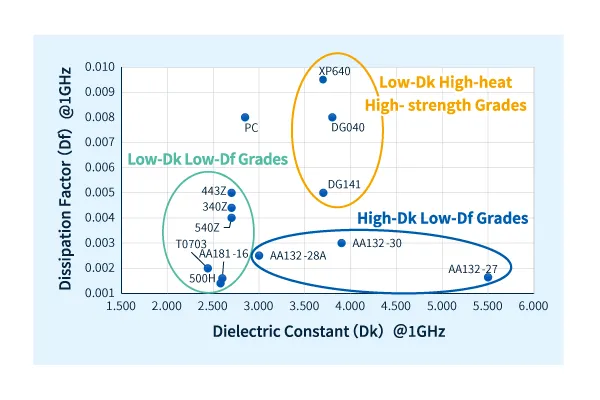

The relative dielectric constant (Dk) and dissipation factor (Df) of the materials that make up 5G communication products and components are key points. In base stations, the relative permittivity and dielectric loss tangent must be controlled to match the component and its location in order to transmit radio waves more efficiently.

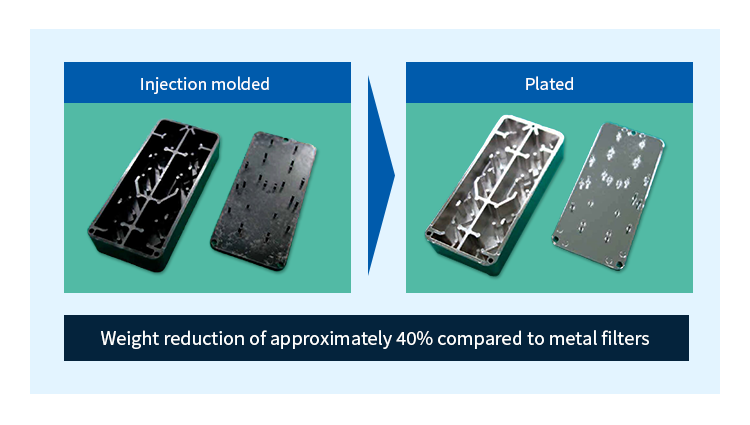

In addition, base stations are equipped with a large number of metal or ceramic filters, which increase the weight, installation man-hours, and workload. Lightweighting the cover, housing, filters, and antennas by using resin and integrating them into complex shapes will contribute to the development of the 5G communication environment.

XYRON™ and SunForce™, whose low dielectric constant (Dk) and low dissipation factor (Df) make it well-suited for use in information and communications field. PPE, the main raw material of PPE also features a high glass transition temperature, and its dielectric properties are less temperature-dependent than those of other high heat-resistant resins. These are important advantages for ensuring stable, high-quality communication across a wide range of operating temperatures.

Asahi Kasei recommends the XYRON™, modified polyphenylene ether (PPE) resins, and SunForce™, a material that is foamed XYRON™, as materials for 5G base stations.

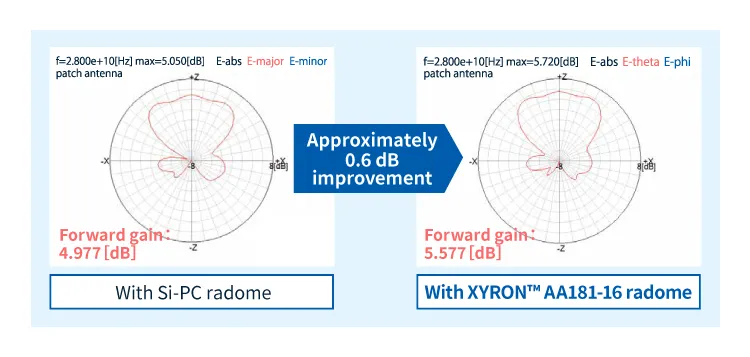

We propose XYRON™ low-dielectric, flame-retardant V-0 grade 443Z, under development material AA181-16, and low yellowing grade under development material 345Z as materials for 5G communication base station antenna covers (radomes).

The XYRON™ family of materials is the right choice to satisfy a wide range of specifications for 5G base-station antenna covers.

| Property | Units | Test method | Test condition | XYRON™ 443Z | Under development XYRON™ 345Z |

Under development XYRON™ AA181-16 |

Si-PC |

|---|---|---|---|---|---|---|---|

| Features | – | Low yellowing | Improved dielectric propertie | – | |||

| DTUL | ℃ | ISO 75-1 | 1.8MPa | 108 | 96 | 106 | 124 |

| Flammability | – | UL94 | – | V-0 (0.75mm) |

V-0 eqiuv. (1.5mm) |

V-0 eqiuv. (1.5mm) |

V-0 (0.8mm) |

| Dielectric Constant | – | SPDR method | 28GHz | 2.7 | 2.8 | 2.6 | 2.8 |

| Dissipation Factor | 28GHz | 0.004 | 0.004 | 0.001 | 0.005 | ||

| Charpy Impact Strength | kJ/ m2 | ISO 179 | 23℃/50%RH | 42 | 35 | 47 | 75 |

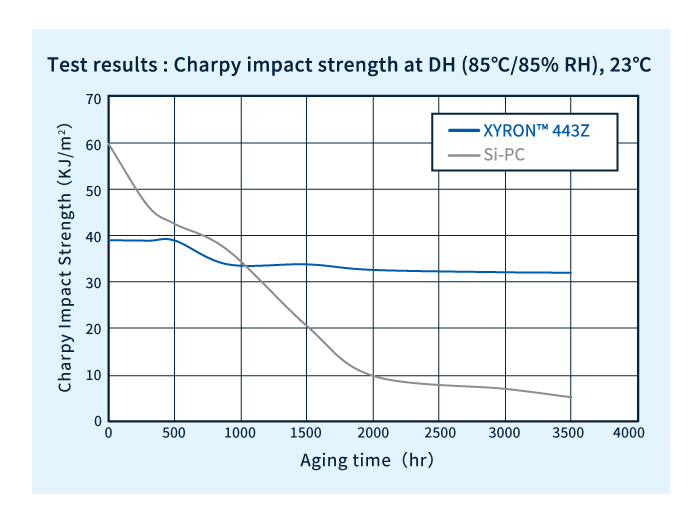

XYRON™ low dielectric and flame retardant V-0 grade has excellent hydrolysis resistance and high impact resistance, and has achieved flame retardancy UL94 V-0 in all colors.Low dielectric and flame retardant V-0 grade 443Z・AA181-16 (under development)

The antenna cover (radome), which is the outermost part, must not only be lightweight and weather resistant, but also have low dielectric properties to improve radio wave transparency. XYRON™ low dielectric flame retardant V-0 grade achieves both flame retardancy (UL94 V-0) and low dielectric properties, which was difficult to achieve with conventional materials.

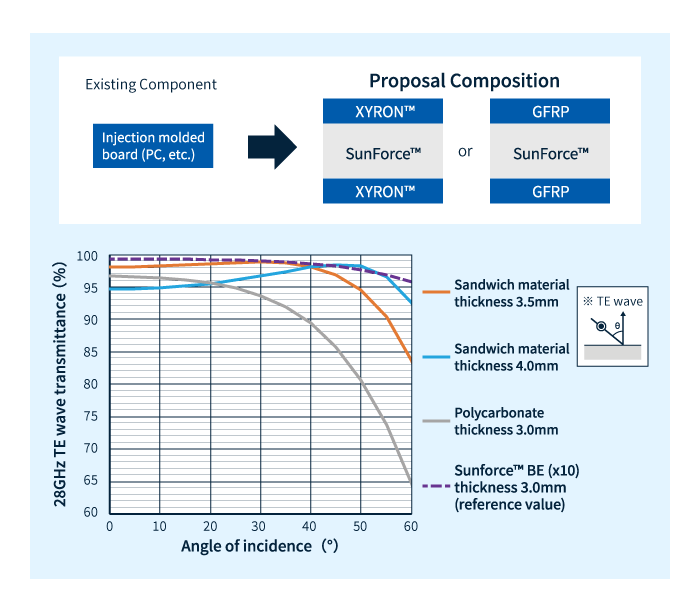

To date, antenna covers have typically been made from polycarbonates (PCs) or similar materials, but this choice leaves much to be desired from the standpoint of dielectric properties. We recommend to use AA181-16 for antenna covers which may eliminate such problems.

XYRON™ low yellowing grade 345Z is a grade that retards weather discoloration while maintaining high flame retardance and impact resistance.

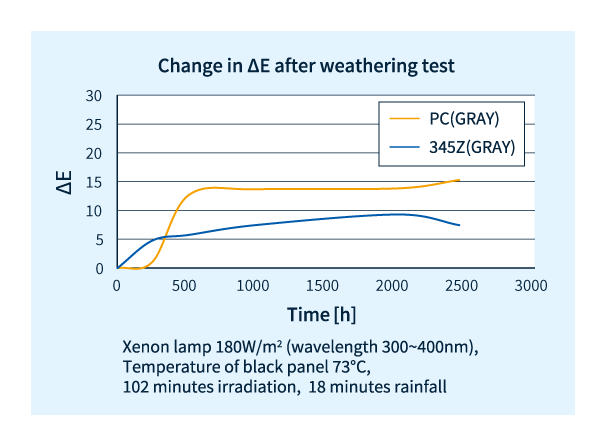

As shown in the figure below, the color difference (ΔE) after weathering test is smaller than that of polycarbonate (PC).

For more information on physical properties and other details, please download slides.

The unique low-permittivity properties of PPE, in combination with Asahi Kasei’s compound-material technology, have allowed us to develop new resin grades with well-controlled dielectric permittivity.

Dielectric materials have wavelength-shortening properties, and have found use in a variety of applications, including dielectric phase shifters and antennas, where the use of high-permittivity (high Dk), low-loss (low Df) materials can reduce size and weight of components.

However, conventional materials offer a tradeoff between high Dk and low Df, and achieving both simultaneously is difficult. To achieve both high Dk and low Df in the same material, Asahi Kasei is developing XYRON™ grades with carefully controlled Dk and Df. These resins are ideal for fabricating miniaturized antennas or dielectric phase shifters for use in base stations.

By proposing dielectric property grades that meet customer needs, we will contribute to the further enhancement of the functionality of next-generation communication base stations.

For more information on physical properties and other details, please download slides.

XYRON™ under develop material AA222-2 is a PPS/PPE alloy with low dielectric properties and improved flame resistance.

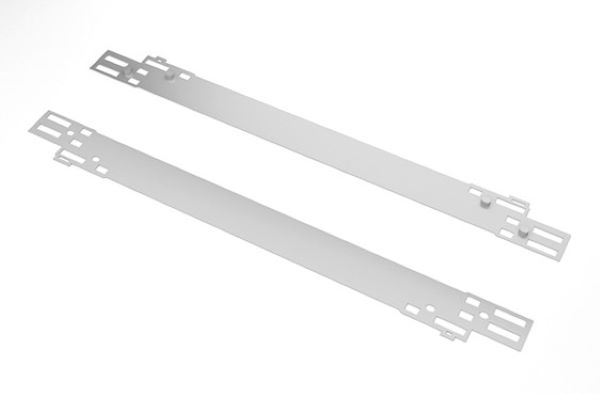

It has a lower specific gravity than PPS, which has been conventionally used for antenna boards (antenna element holders), enabling weight reduction. It also has excellent platability and workability (low warpage and low flash).

For more information on physical properties and other details, please download slides.

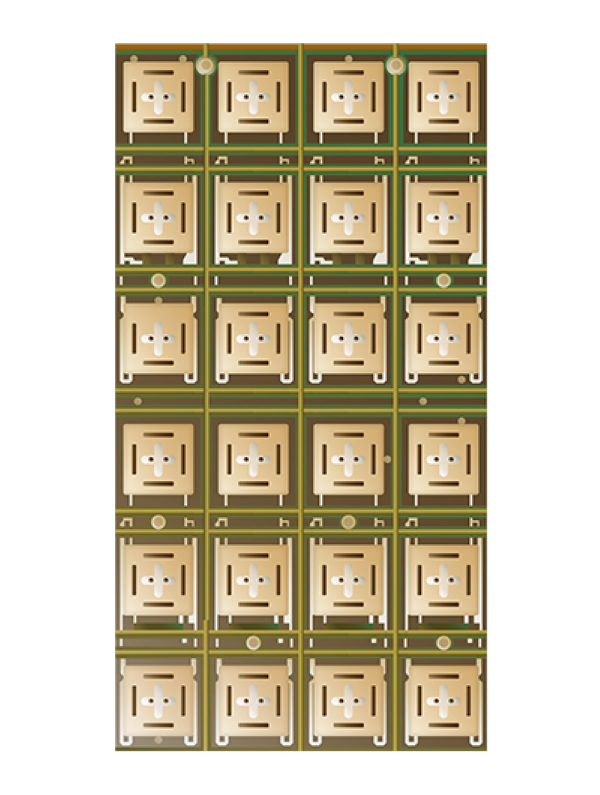

Asahi Kasei is developing XYRON™ grades for RF cavity filters in 5G base stations.

Base stations commonly incorporate large numbers of metal or ceramic RF filters and slotted waveguide array antennas that increase system weight, complicating installation, and increasing operating losses. The greater density of base stations required for 5G networks makes these factors even more important—and creates an urgent demand for lighter-weight components.

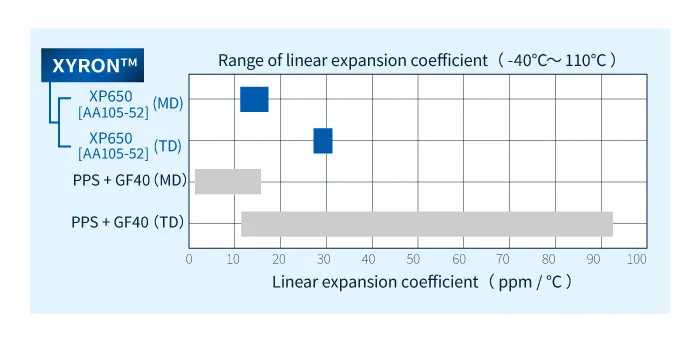

XYRON™ XP650 (AA105-52) has high heat resistance and low linear expansion equivalent to that of metal, making it a material that can contribute to the resinification of RF filters and gap waveguide slot array antennas.

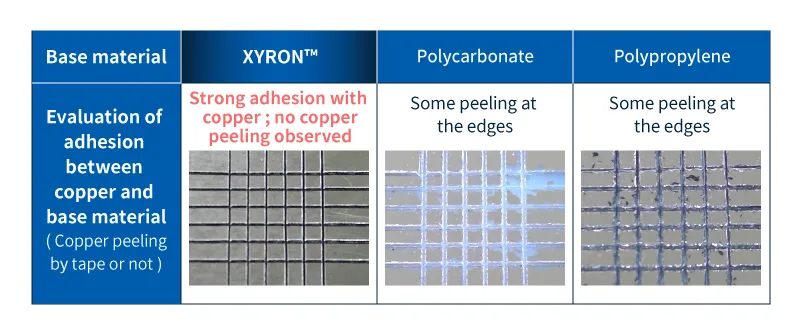

In addition, XYRON™ has excellent plating properties and adheres better to copper than other materials such as polycarbonate and polypropylene, as shown in the evaluation results below.

XYRON™ XP650 (AA105-52) has a stable low coefficient of linear expansion over a wide temperature range, making it optimal Materials for reducing the weight of metal products that require dimensional stability in a wide range of temperature environments.

For more information on physical properties and other details, please download slides.

Sunforce™ is a bead foam made from modified PPE resin XYRON™, which has low dielectric properties, resulting in extremely low dielectric characteristics. This reduces electromagnetic wave attenuation at high frequencies.

Below, we present applications for 5G base-station uses that leverage the properties of SunForce™.

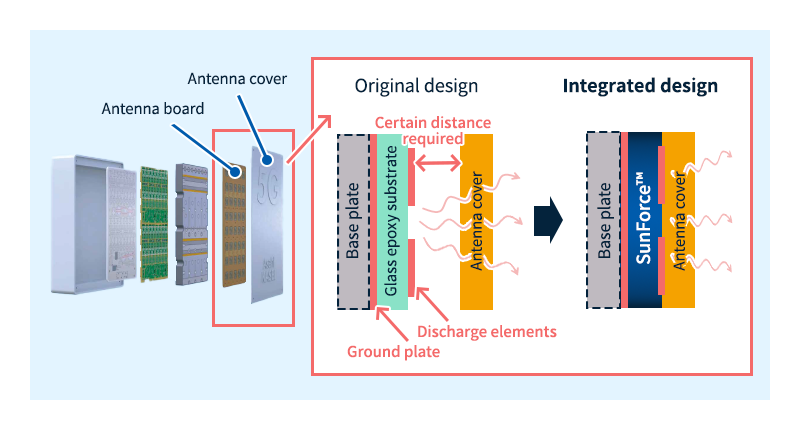

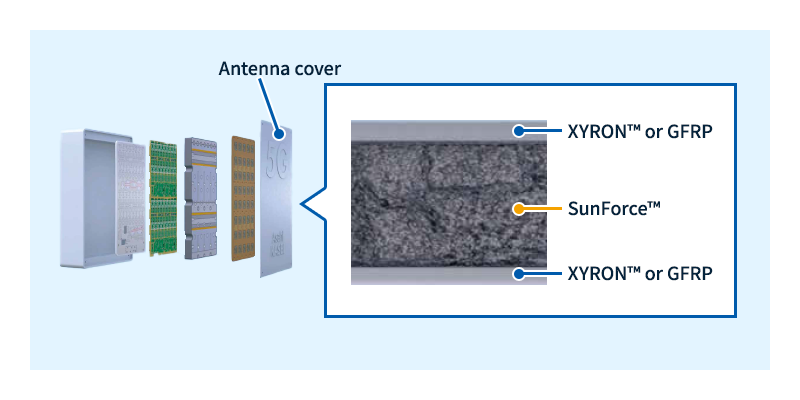

By integrating a radome made of XYRON™, has pre-formed antenna discharge elements through plating, with a SunForce™ spacer that determines the distance between the ground plate and the discharge elements, we can create an integrated antenna radome characterized by high radio wave radiation efficiency, thinness, and high rigidity.

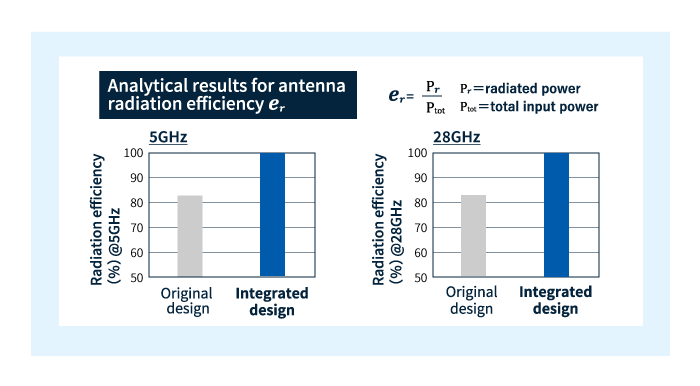

TThis integrated antenna configuration significantly improves radio wave radiation efficiency compared to existing configurations, as shown in the diagram below. This enhancement is achieved by suppressing surface waves (entrapment of radio waves due to total reflection at the material interface) through the low dielectric nature of the substrate (SunForce™) and the integration of the radome.

By applying SunForce™, characterized by its low dielectric constant, as a core material in sandwich construction for radomes made of XYRON™ or GFRP, it is possible to create a radome that maintains high stiffness and offers high radio transparency in both frontal and oblique directions. Additionally, using a foam core contributes to weight reduction.

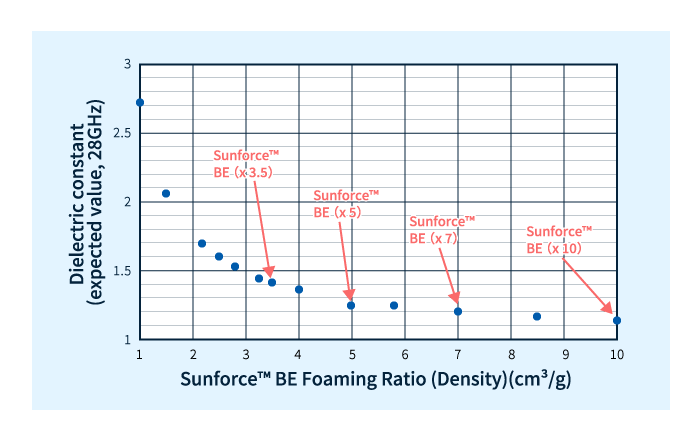

In addition to having low dielectric properties, SunForce™ also possesses a characteristic that allows the control of its dielectric constant by adjusting the foam expansion ratio (density), as shown in the diagram below.

Leveraging this characteristic, SunForce™ can be applied to the components of dielectric lenses that are used to control the directivity and intensity of radio waves.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.