product

Excellent flame retardancy, electrical properties, dimensional stability, and water resistance. It is used in photovoltaics, batteries, and communication components.

NEW SERVICE!

CAE ServicesFor inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

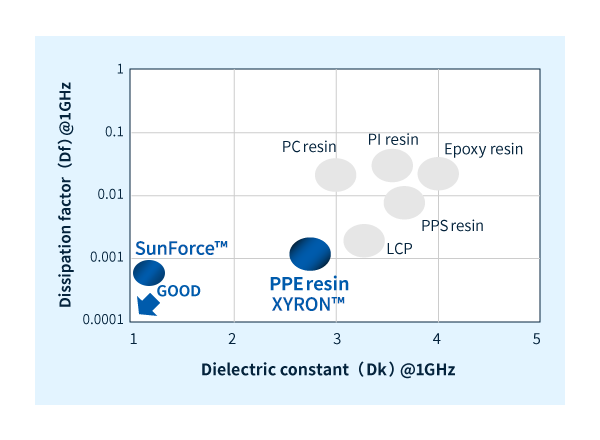

The nature of 5G networking requires that hardware devices be designed to minimize attenuation of high-frequency electromagnetic signals.

This, in turn, demands that the components of these devices be made from materials with low dielectric constant (Dk) and low dissipation factor (Df). The relative dielectric constant (Dk) and dissipation factor (Df) of a material are physical properties that control the attenuation of electromagnetic signals in the material; materials with high permittivity or high loss tend to absorb electromagnetic signals, increasing signal losses and degrading communication sensitivity.

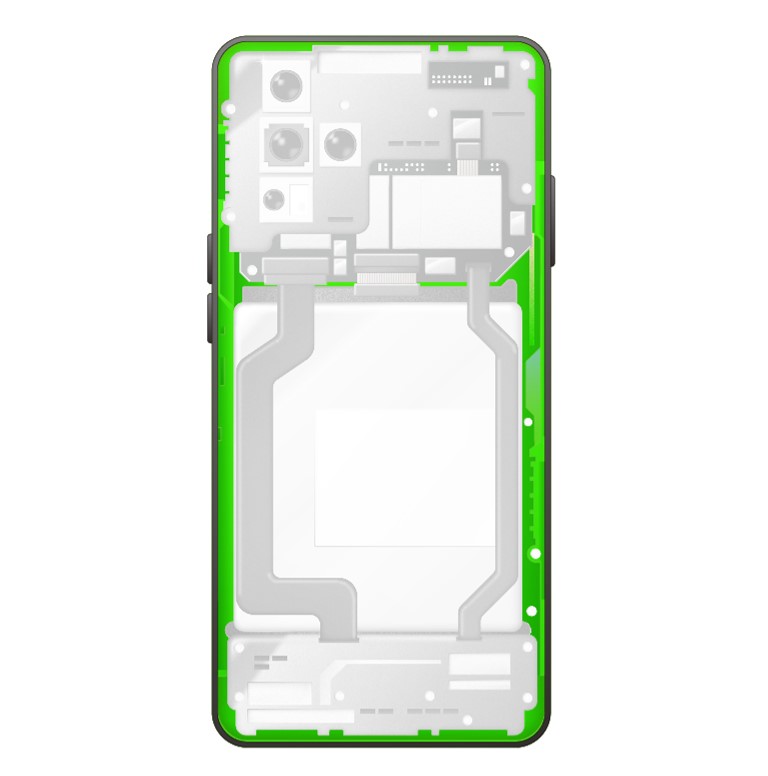

Furthermore, smartphone users tend to prefer devices with slim cases, and the challenge of squeezing components into the thinnest possible case is a key aspect of smartphone terminal design.

To this end, terminal designers have pursued a variety of miniaturization strategies, including: careful selection of materials for cases, frames, and antennas; designs that eliminate interconnect wiring; modularization of various components; and flexible printed circuit boards.

Asahi Kasei recommends our XYRON™ modified polyphenylene ether resins as materials for 5G network components, including smartphone and base stations.

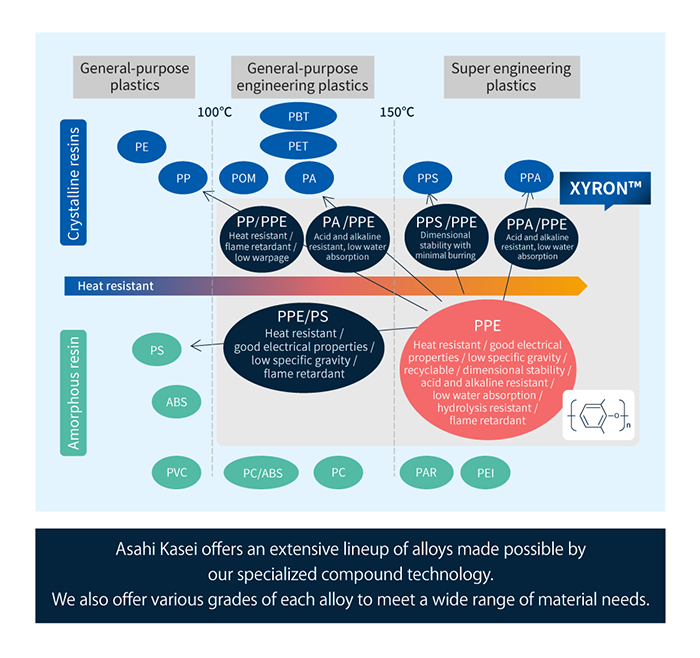

XYRON™ is polymer alloy combining polyphenylene ether (PPE) with other resins. Asahi Kasei's

The XYRON™ family, which Asahi Kasei has been producing since 1979, boasts an extensive track record—occupying a key role in the history of engineering plastics—and today encompasses an extensive lineup of polymer alloys.

XYRON™ offers multiple excellent physical properties.

In addition to their high heat resistance, they boast excellent flame retardance and electrical insulation, dimensional stability, and water resistance, as well as low specific gravity. These polymer alloys combine the advantages of PPE with the specialized properties of various other resins to yield unique functional materials.

To date, XYRON™ has been used to make components and cases for a wide range of industrial sectors, from automobiles to household appliances.

For automobiles, in particular, the combination of low specific gravity with high heat resistance and flame retardance has made the use of XYRON™ a popular strategy for reducing the weight of on-board components.

XYRON™ products is polyphenylene ether (PPE), whose low dielectric constant (Dk) and low dissipation factor (Df) make it well-suited for use in information and communications field.The parent material of all

PPE also features a high glass transition temperature, and its dielectric properties are less temperature-dependent than those of other high heat-resistant resins. These are important advantages for ensuring stable, high-quality communication across a wide range of operating temperatures.

In keeping with our commitment to develop innovative materials for sustainable societies, Asahi Kasei is proud to introduce a new addition to our XYRON™ family of modified polyphenylene-ether resins: recycled PET/PPE alloys for 5G smartphone terminal chassis, especially for US, India and Japan market*.

Asahi Kasei is working to develop recycled XYRON™ grades that combine PPE with various recycled resins to yield sustainable manufacturing without sacrificing the high performance of these unique materials.

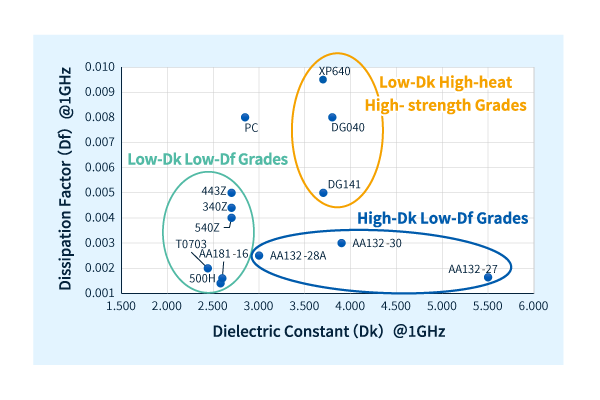

XYRON™ recycled PET/PPE alloys use approximately 40% post-consumer recycled resins—recovered from PET bottles and other items—while retaining the good mechanical properties and low dielectric properties (low dielectric constant (Dk) and low dissipation factor (Df)) of conventional XYRON™ grades.

These resins, which allow bonding to metals, are ideal for use as advanced chassis materials for smartphone terminals: not only are they derived from recycled products, but they also a boast lower dielectric properties than currently used PBT+GF materials. This material can be applied to chassis for tablets, laptop or note PC.

.png)

XYRON™ low dielectric LDS grades, which are in development for MID antennas, have been certified in March 2024 as approved plastics* for LPKF LDS technology.(Click here for details on LPKF's LDS technology and the list of certified materials.)

*Laser Direct Structuring (LDS) is a 3D conductive trace technology (MID technology) developed by LPKF Laser & Electronics. To use materials for this technology, certification from LPKF is required. In the LDS process, a resin material dispersed with metal complexes is used, and the complexes are reduced by laser light to form catalytic nuclei, which are then selectively plated to create the circuitry.

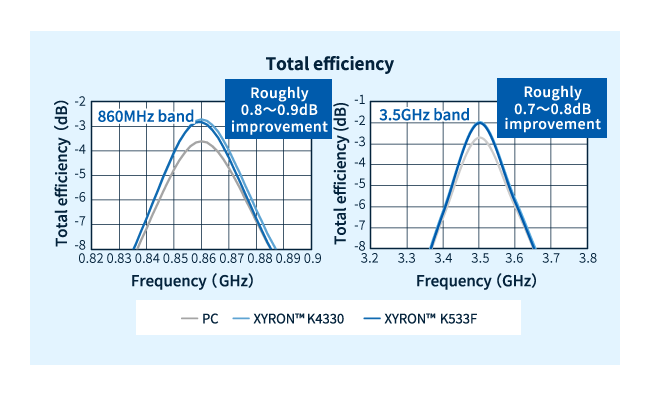

The outstanding properties of these grades include their low dielectric constant (Dk) and low dissipation factor (Df), and high hydrolysis resistance. Simulation results indicate that the use of these materials in MID antennas can improve total efficiency by as much as 1 dB compared to the polycarbonate (PC) materials conventionally used for this purpose.

We offer to use this material which may enable operation at higher frequencies and more advanced device functionality, alleviating design space constraints to facilitate your development process.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.