Product

Excellent heat resistance, strength and toughness, insulation, and oil resistance. It is widely used in automotive parts, electrical and electronic parts.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

An Advanced Driver-Assistance Systems (ADAS) is a driving-support technology designed to make automobile journeys safer and more comfortable for drivers.

This page introduces various Materials for in-vehicle cameras and head-up displays (HUDs), which are among the representative sensors and devices that make up ADAS.

*Click herefor details on “Materials for ADAS millimeter-wave radars”

Asahi Kasei offers high-performance resin materials for cameras, head-up displays, and other ADAS components—with accompanying technical support services—to help make transportation safer and more comfortable.

Vehicle-mounted cameras require materials that offer a good balance of outstanding properties in several key areas.

For a wide variety of vehicle-mounted camera components—including lens barrel, lens spacers, and chassis bodies—Asahi Kasei recommends our XYRON™ XP640, AA105 (development product), and DG040.

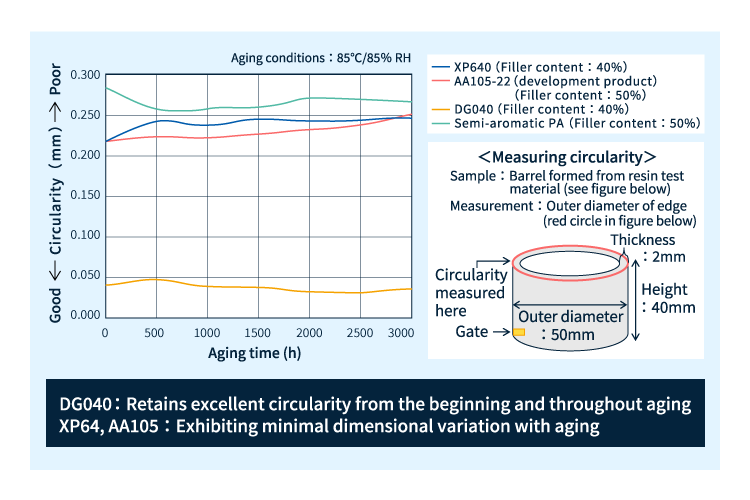

The figure below shows the results of aging tests in which several resin materials were formed into the shape of a lens barrel, then subjected to aging with periodic measurements to assess their ability to retain a precisely circular shape (a property known as circularity). XYRON™ DG040 exhibited high circularity from the earliest stages of the experiment—and minimal variation with aging, demonstrating that this material offers particularly outstanding dimensional stability. XYRON™ XP640 and AA105 (development product) also exhibited minimal dimensional variation with aging, confirming the excellent dimensional stability of these materials as well.

These are alloy grades blending PPE with high heat-resistant Polyphthalamide (PPA). When PPE, a material famous for its low water absorption, is alloyed with PPA, the result is a material offering the high heat resistance and high strength of PPA, but exhibiting minimal dimensional variation due to low water absorption. AA105, a product currently in development, boasts greater weather resistance than XP640 and features high laser transmissivity, making it suitable for laser welding.

Click here to view the XYRON™ XP640 datasheet.

This is an alloy grade blending PPE with PPS. Its key advantages include (a) minimal degradation in mechanical strength in high-temperature environments, and (b) minimally anisotropic dimensional variation thanks to specialized glass-fiber reinforcements.

The materials used to make camera components must offer high dimensional accuracy with minimal variation in component dimensions and dimensional stability across a range of operating environments. For enclosures, it is particularly important to choose materials that are attractive in appearance.

Meanwhile, room mirror brackets are no longer simply mounting points for mirrors, as was true in the past; instead, these components have begun to acquire various new types of sensing capability. This, in turn, imposes new requirements on the materials from which these components are made: materials must be heat-resistant, to ensure they can withstand the heat generated by sensing components, and must offer high rigidity to support increased weight. The resin materials used here must be attractive in appearance—as they will be used for interior components—and must offer high rigidity for vibration suppression and minimal variation in component dimensions or material properties upon water absorption.

Asahi Kasei’s LEONA™ SG105 and SG115 polyamide resins are alloy grades that blend semi-aromatic polyamide 6I with polyamide 66.

These materials feature reduced variation in component dimensions and material properties due to water absorption, and offer high relative strength, high rigidity, attractive appearance, and excellent fluidity.

Resin materials for use in head-up displays must offer high dimensional accuracy—with minimal dimensional variation at high temperatures when mounted in vehicle dashboards—to ensure that mirrors properly reflect and project display images.

For head-up displays, Asahi Kasei recommends the following two XYRON™ grades.

XYRON™ DG040 is an alloy grade blending PPS with PPE. Adding PPE to PPS improves dimensional stability at high temperatures, while the addition of specialized glass fillers reduces anisotropy in dimensional variations.

Click here to view the XYRON™ DG040 datasheet.

XYRON™ 744Z is an alloy grade blending PPE and PS. This material offers compliance with the UL V-0 flame-retardant standard, a heat deflection temperature of 135°C, and a good balance of heat resistance, toughness, and dimensional stability.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.