product

Excellent heat resistance, strength and toughness, insulation, and oil resistance. It is widely used in automotive parts, electrical and electronic parts.

NEW SERVICE!

CAE ServicesFor inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

Laser marking is a technique to create marks on an object, in which laser beam emitting a target body induces melting, burning, cutting, or discoloration of the body surface.

The growing importance of techniques for marking items to ensure quality control and traceability can be seen all around us: one need only consider the ubiquity of barcodes for identification, product names, model numbers, and many other types of marked information.

Laser marking is a highly reliable technique that offers many advantages and is used for a wide range of purposes. Laser marking requires no preprocessing and can create readable marks of texts (including serial numbers and lot numbers), machine-readable data (such as barcodes, 2D codes and QR codes), numbers, letters, logos, signs, photos, pictures, patterns, graphics simply through laser beam emission alone, ensuring that products themselves remain unaffected in quality.

Marking performance is affected by factors such as the type of plastics used, the dyes they contain, and the type of laser. In general, engineering plastics are highly suitable for laser marking; however, even in cases of poor marking performance, minor adjustments involving additives and/or coloration prescriptions often suffice to yield significant improvements.

Asahi Kasei develops and sells the LEONA™ SN series of polyamide featuring excellent laser-marking behavior.

Asahi Kasei develops and sells theLEONA™ SN series,of polyamide featuring excellent laser-marking behavior.

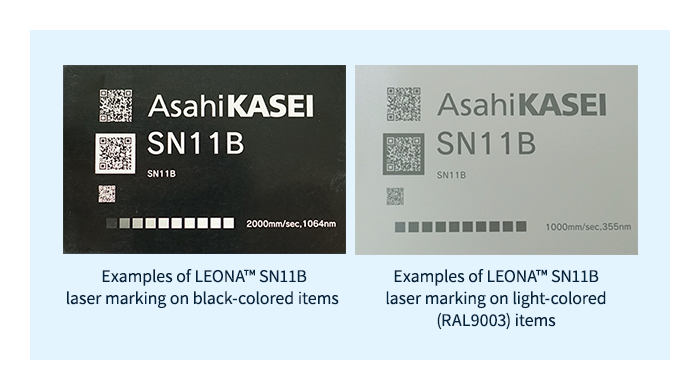

Laser marking with LEONA™ SN Series resins yields clearer, higher-contrast lettering than typical non-halogen flame-retardant polyamide resins in both of the following situations:

①Forming white letters on black-colored items

②Forming black letters on white, gray, or other light-colored items (including RAL9003 and RAL7035)

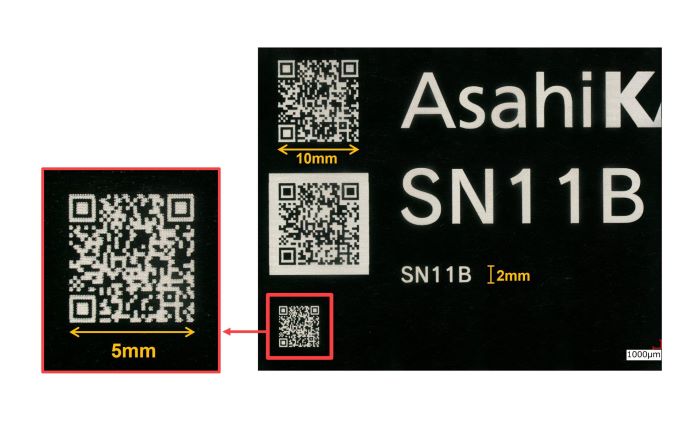

The following video demonstrates laser marking of a two-dimensional code in an extremely compressed space—side length of just 5 mm—with sufficiently high quality to allow immediate recognition by a cell-phone camera.

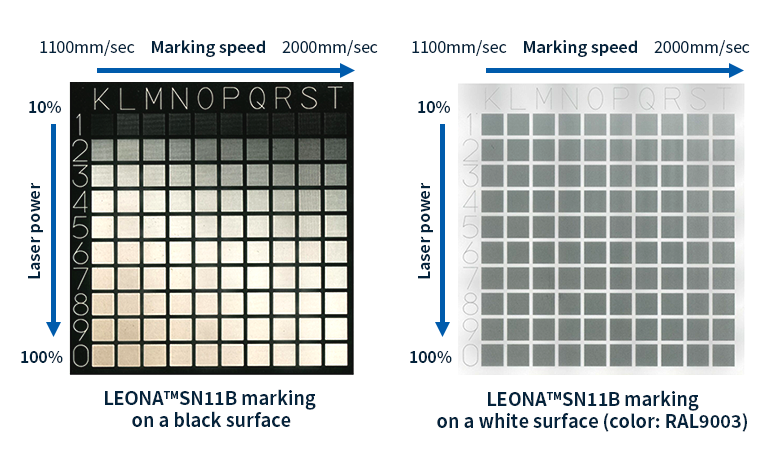

The figures below show examples of laser-marking results obtained for various combinations of laser power and marking speed. Laser marking with LEONA™ SN-series resins produces clear results even at high marking speeds above 1,000 mm/sec.

These results demonstrate how laser marking with LEONA™ SN-series resins can produce high clarity with excellent performance under a broad range of operating conditions. This capability allows a reduction in the product area required for marking, helping to miniaturize products and increasing product-design freedom.

Moreover, the two-dimensional codes that have recently become increasingly common are more time-consuming than letters to inscribe by laser marking; choosing LEONA™ SN-series resins helps to reduce these marking-time requirements.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.