product

Excellent heat resistance, strength and toughness, insulation, and oil resistance. It is widely used in automotive parts, electrical and electronic parts.

NEW SERVICE!

CAE ServicesFor inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

Metal replacement is simply the act of replacing a metallic component—which may be made of iron, aluminum (Al), stainless steel (SUS), brass, or any other metal—with a similar component made of plastic.

Metals have traditionally been the material of choice for components requiring high durability, high heat resistance, or other similar properties. However, the development of high-performance engineering plastics has made it possible to replace some metallic components with plastic components without sacrificing performance. This can offer numerous advantages, including lighter-weight components, reduced component count, elimination of painting and coating/plating processes due to the natural attractiveness of resin materials, and reduced costs.

For example, metal replacement iron components with resin components are between 5 and 6 times lighter in weight, as can be seen simply from a comparison of specific weights (the specific gravity of resins is around 1.3-1.4, compared to 7.8 for iron). Similarly, replacing aluminum components with resin components yields a weight reduction of roughly twofold (specific weight of aluminum=2.7).

An additional point is that metals, despite the extraordinarily broad variety of products for which they are used, often prove problematic when used to produce products with complicated shapes, as this may require lengthy and cumbersome sequences of post-processing steps in which metal plates are punched, bent, or twisted, and multiple components are combined. In contrast, resins can be easily molded into highly flexible shapes with essentially arbitrary complexity, limited only by the constraints of mold designs. Consequently, metal replacement may allow a single resin component to replace multiple metallic components, simplifying post-processing steps and reducing costs.

At Asahi Kasei, we are using our line-up of high-performance engineering plastics to explore metal replacement of metallic components in a wide range of fields.

Hardware accessories such as crescent locks and hinges for doors must need high strength and are thus typically made from metal. However, the plating processes required for metallic components generate waste liquids contaminated by metal ions, resulting in significant environmental impact.

Metal replacement these components with Asahi Kasei’s LEONA™ 90G or LEONA™ SG series—visually attractive materials well-suited for applications to stylish designs—yields fully functional crescent locks and hinges that are warm to the touch and manufactured without coating/plating or painting.

In addition, the use of AGI molding for resin crescent locks helps to mitigate problems associated with sink and warping.

Nuts used to fix the position of hardware components are typically made of metal. However, in automobiles and other systems containing large numbers of nuts, the weights of individual nuts add up to constitute a significant fraction of the overall system weight.

Metal replacement these components with Asahi Kasei’s LEONA™ 90G55 yielded a weight reduction of 6 g per component—or roughly 1 kg per automobile—thus helping to improve fuel efficiency. In addition, the smoother surfaces of the resinized nuts improved operating efficiency and reduced the need for repairs.

The chassis cases used to house air-pressure regulators (solenoid valves)—components that assist in automation and are embedded in instruments and equipment installed at manufacturing sites—must be high in strength, and thus are typically made from metal.

However, the labyrinthine networks of tiny fluid-flow pathways used to control air in these components force them to have complicated shapes, requiring lengthy multi-step manufacturing processes entailing significant material losses.

Metal replacement these components using Asahi Kasei’s LEONA™ S series of high-strength resins streamlined post-processing and helped to simplify manufacturing.

Battery cases in electric vehicles are typically made from metals such as steel or aluminum. The goal of reducing component weight to extend vehicle travel distance suggests the possibility of switching to resin materials, but typical resins cannot offer the required thermal resistance; also, cost reduction is a perennial issue.

By using Asahi Kasei’s continuous glass fiber reinforced thermoplastic (c-GFRTP) to replace metals, we are able to contribute to the reduction of weight, leading to an increase in the distance traveled by automobiles.

CAE is a design technique in which computer simulations are used to build and test prototype products in virtual environments, enabling the development of high-performance products with short lead times and low costs.

Asahi Kasei uses resin CAE techniques to propose high-performance plastics product design with short lead times and low costs. Please contact us for more details if you have any issues on weight reduction or cost reduction of metal parts.

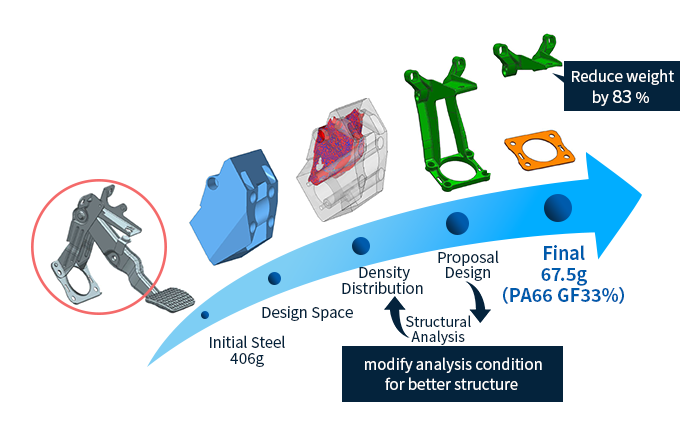

Asahi Kasei’s topology optimization is a technique that uses computer simulations to optimize the structure of a component made of plastics. This process infuses product designs with new insights that might not be evident from the shape of the original metallic component.

Here we present a case study in which Asahi Kasei engineers used topology optimization to design a lightweight replacement for a metal brake pedal bracket.

The first step was to model the design space of the brake pedal bracket to avoid interference with other system components. From this design space, several candidate designs were constructed.

These were then analyzed to check whether or not they satisfied performance requirements, and an optimal shape—taking into account a range of factors including weight and ease of manufacturing—was determined.

Through this process, engineers concluded that the component could be redesigned with a new shape and lighter weight, and proposed metal replacement using Asahi Kasei’s LEONA™ 14G33 (33% glass-reinforced polyamide 66), achieving an 83% weight reduction.

As these case studies illustrate, Asahi Kasei is exploring metal replacement opportunities in a wide range of domains. When designing metal replacement strategies, it is important to account for differences in the physical properties of metals and plastics and to consider the environment in which components will be used. If you have metallic components that weigh or cost more than you would like, please do not hesitate to contact us to discuss metal replacement solutions.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.