Product

Excellent flame retardancy, electrical properties, dimensional stability, and water resistance. It is used in photovoltaics, batteries, and communication components.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

OA equipment is an abbreviation for Office Automation, and is a general term for information equipment for companies that makes office work more comfortable, and includes printers, personal computers, projectors, shredders, etc. Printer is a general term for printing machines, and OA equipment printers mainly refer to multifunction machines and multifunction printers that have fax, copy (copy), and scan functions. This printer has various printing methods (methods of transferring information to an object such as paper). The printing methods of printers can be broadly divided into two types: impact methods and non-impact methods.

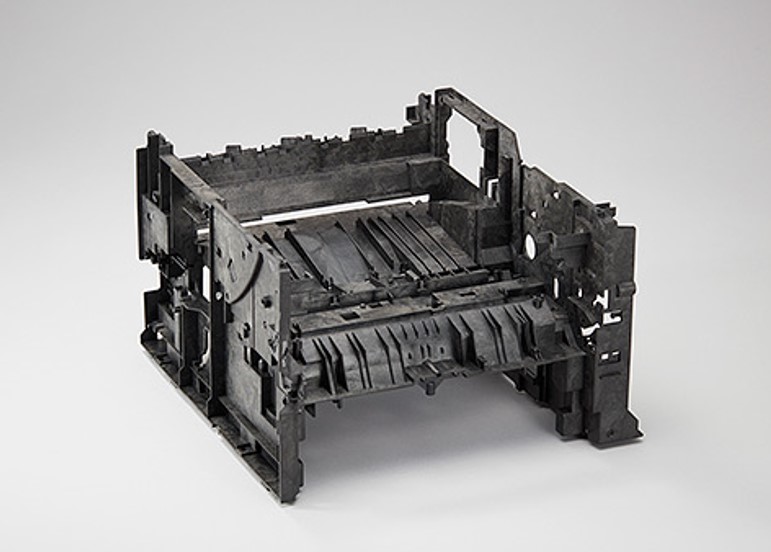

We introduce the modified PPE resin XYRON™, which is used for printer internal chassis and ink head peripheral parts, and the POM resin TENAC™, which is used for various gears, mechanical parts, conductive bearings.

Asahi Kasei 's Flame retardance modified PPE (modified polyphenylene ether) resin "XYRON™" is a halogen-free, PFAS-free Materials that achieves high flame resistance.

We have a wide range of grades from V-1 to 5VA, and some thinner grades have been certified as 5VA and 5VB and have passed the S2 test. Please contact us for more information.

XYRON™ has a proven track record in many applications for office automation equipment, including chassis parts, optical boxes, carriages, fixing peripheral parts, and power supply cases.

Generally, the chassis parts and fixing parts of office equipment often use materials that contain PFAS as Flame retardance auxiliary agents (such as PC resins) or materials that use halogenated Flame retardance (such as PET and PBT resins). However, due to the recent increase in environmental awareness, the Electronic Product Environmental Assessment Tool (EPEAT), a certification that certifies that electronic products are environmentally friendly, is expected to be revised in 2025 to impose restrictions on the use of halogenated materials*. In addition, future restrictions on PFAS are also under discussion.

*Reference: 2nd Public Consultation: EPEAT Chemicals of Concern Criteria

XYRON™ Flame retardance grades are halogen-free and PFAS-free, making it possible to propose solutions that meet these market needs.

[Halogen-free and PFAS-free XYRON™ Flame retardance grade]

|

Grades |

Features |

Applications |

|---|---|---|

|

XYRON™ 540Z |

reinforced highly Flame retardance grade that has passed the S2 combustion test |

Power supply case parts |

|

XYRON™ X7744 |

reinforced Flame retardance grade that achieves high stiffness and low warpage in balance with GF |

Chassis, optical box, carriage, etc. |

|

XYRON™ X444V |

reinforced Flame retardance grade that achieves high stiffness and low warpage in balance with GF |

|

|

XYRON™ X523V |

reinforced Flame retardance grade (30% inorganic filler) that uses inorganic filler to achieve high stiffness and high dimensional accuracy |

Asahi Kasei is working to develop recycled XYRON™ grades that combine PPE with various recycled resins to yield sustainable manufacturing without sacrificing the high performance of these unique materials.

This recycled grade of XYRON™ can utilize up to 40% post-consumer recycled resin.

In addition, based on the concept of local production for local consumption, we aim to procure recycled resin from each processing plant, and in addition to reducing our carbon footprint, we have established a system that pays attention to BCP and logistics.

We are also developing a new alloy recycling system that utilizes PCR resin. We are also looking for partners for closed schemes that enable closer development with customers.

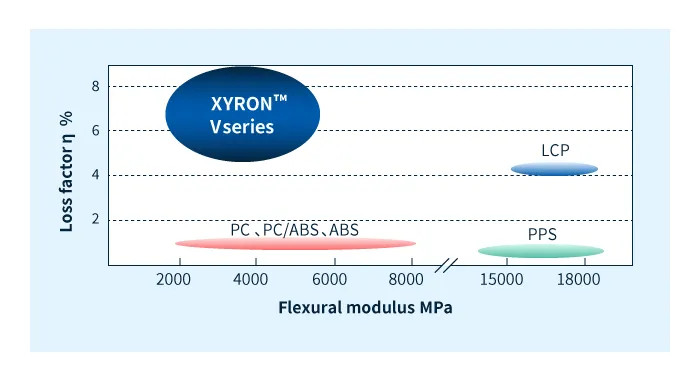

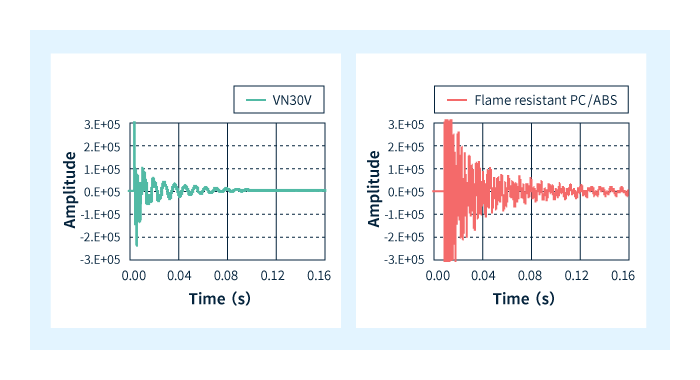

XYRON™ V Series is a high loss coefficient vibration damping material that achieves vibration damping performance 5 to 10 times that of PC, PC/ABS, or ABS.

The characteristics of this material are as follows.

XYRON™ DG series is a revolutionary material that retains the characteristics of PPS, which is a crystalline resin, and PPE, which is an amorphous resin, while significantly improving the shortcomings of each.

The characteristics of this material are as follows.

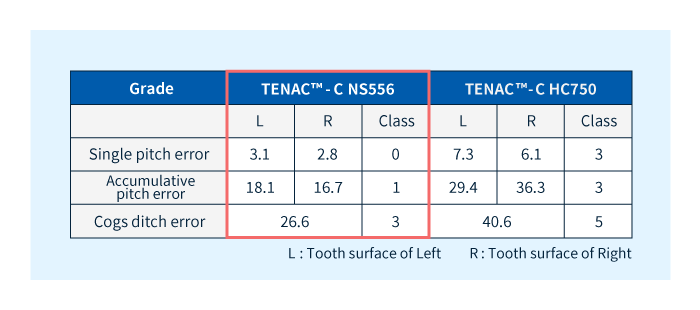

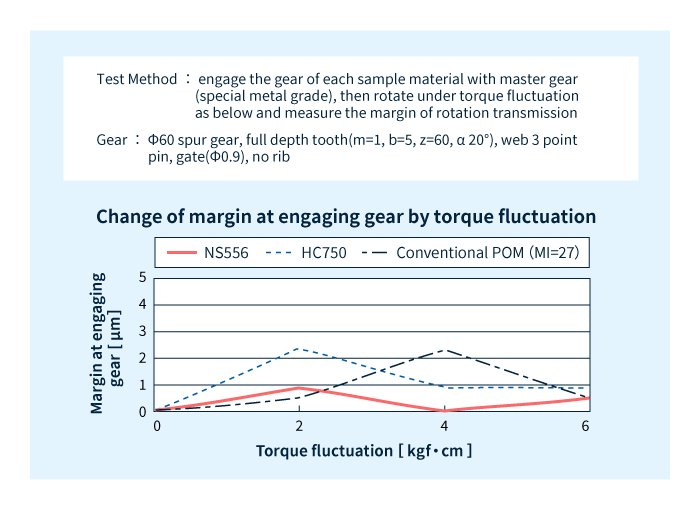

TENAC™-C NS556 is a next-generation compound material that achieves both high stiffness and high precision, which have been difficult to achieve until now, while also providing durability.

The features of TENAC™-C NS556 are as follows:

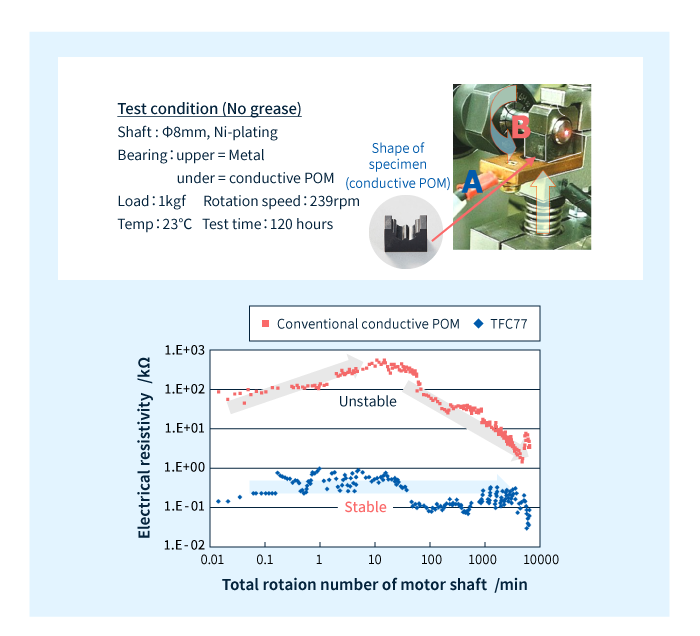

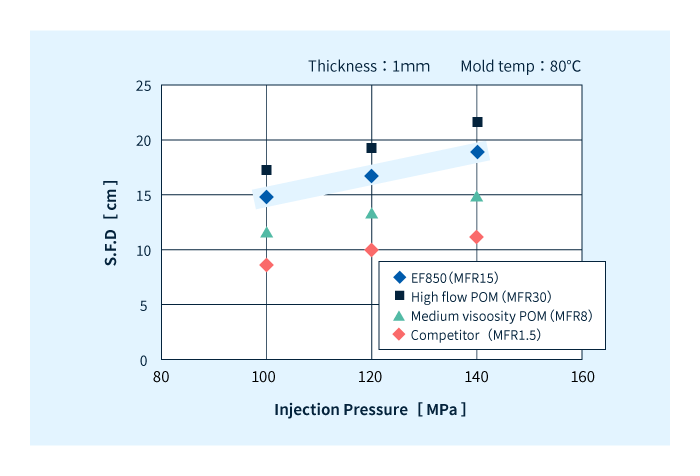

In addition, TENAC™ -C EF850 is based on highly fluid polyacetal resin, and is designed with special carbon black to prevent static electricity.It has good conductivity and high fluidity (MFR: 15 g/10min (190℃, This is a grade that achieves both 2.16kg load)).

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.