Product

Excellent flame retardancy, electrical properties, dimensional stability, and water resistance. It is used in photovoltaics, batteries, and communication components.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

With environmental regulations and exhaust-gas restrictions growing stricter in Europe and elsewhere—and efforts to restrict CO2 emissions expanding around the world—different nations and regions have different regulations and policies regarding electric vehicles and other emerging vehicle technologies such as hybrid and fuel-cell vehicles.

Although CO2 emissions from automobiles are already regulated at strict levels, in the future we will see increasingly stringent emission standards that will not be achievable through improvements in engine efficiency alone.

The biggest challenge for EV (electric vehicle) batteries is to increase their energy density, which can extend the vehicle's range without compromising space or weight.

Asahi Kasei has over 20 years of experience in manufacturing high-performance engineering plastics for automotive batteries, and can support your manufacturing needs.

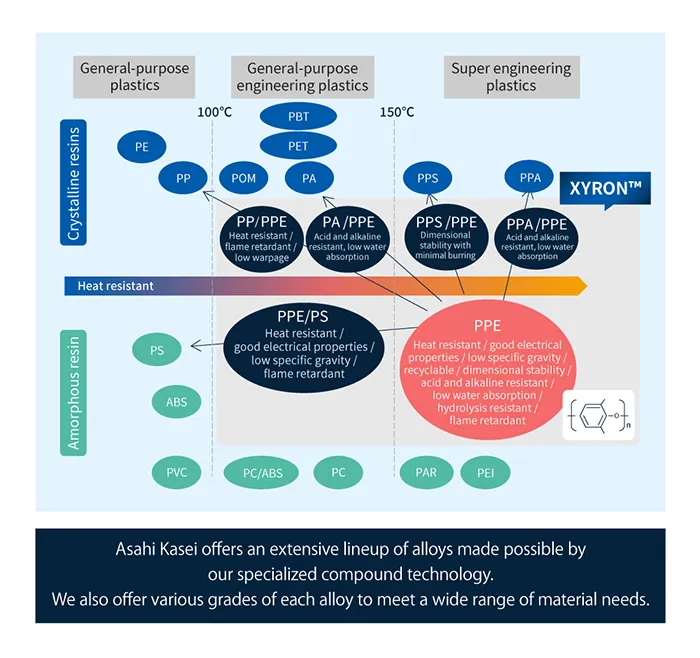

XYRON™ is polymer alloy combining polyphenylene ether (PPE) with other resins. Asahi Kasei’s The XYRON™ family, which Asahi Kasei has been producing since 1979, boasts an extensive track record—occupying a key role in the history of engineering plastics—and today encompasses an extensive lineup of polymer alloys.

XYRON™ materials offer multiple excellent physical properties. In addition to their outstanding heat resistance, they boast flame retardance, electrical insulation property, good dimensional stability, and hydrolysis resistance, as well as low specific gravity. These polymer alloys combine the advantages of PPE with the specialized properties of various other plastics to yield unique functional properties.

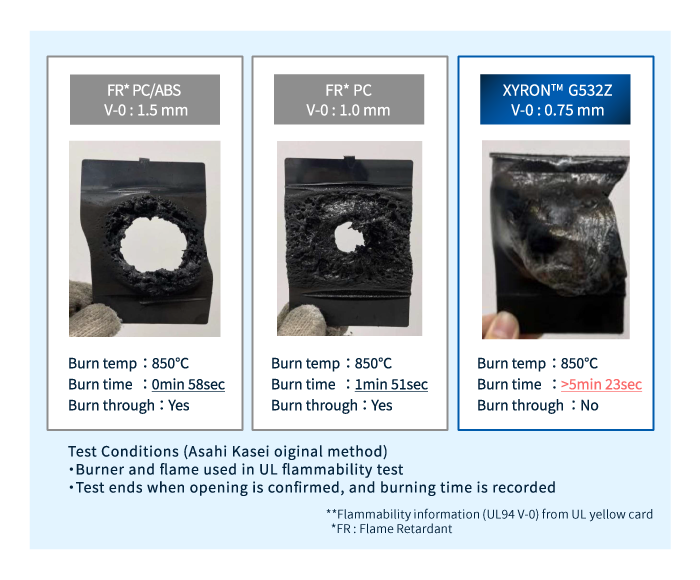

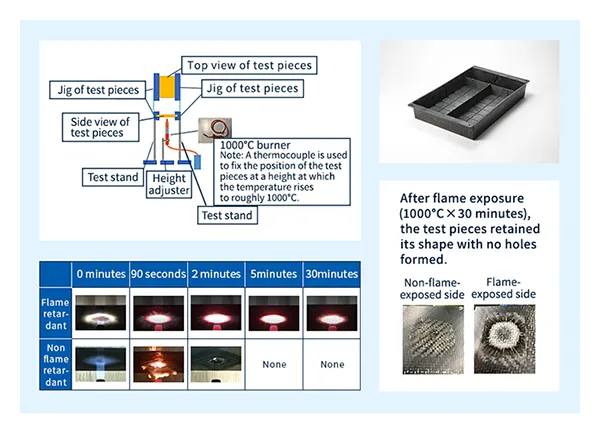

XYRON™ resins have a high oxygen index (a measure of the volume of oxygen required for burning), making them highly flame retardant. In the figure below, a flammability test was conducted using the burner and flame used in UL's flammability test. Under unique conditions, XYRON™ was able to confirm the high flame retardancy.

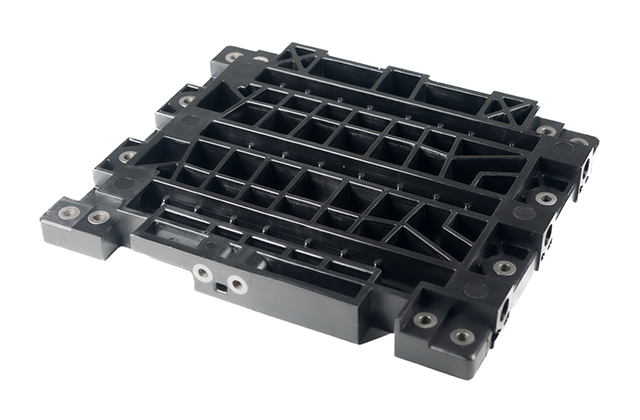

The intercell spacer, which is an insulating component used between battery cells, is made of XYRON™ 340Z, which has excellent tracking resistance, hydrolysis resistance, acid/alkali resistance, and long-term stable physical properties, and in addition to these characteristics, it also has oil resistance. We suggest the use of PP/PPE Alloy XYRON™ TF series, which has chemical resistance.

Good thin wall formability contributes to space saving and weight reduction. Furthermore, it has excellent creep properties and flame resistance (non-halogen), contributing to vehicle safety.

Click here to view the XYRON™ 340Z datasheet.

Click here for details on XYRON™ TF series

When weight reduction and dimensional stability are important for insulating protective covers for conductors carrying high voltage and current, we recommend XYRON™ 440Z and 443Z, which have thin-wall formability, insulation properties, and heat resistance.

We also offer the oil resistance XYRON™ T series, which makes handling easier.

Click here to view the XYRON™ 440Z datasheet.

Click here to view the XYRON™ 443Z datasheet.

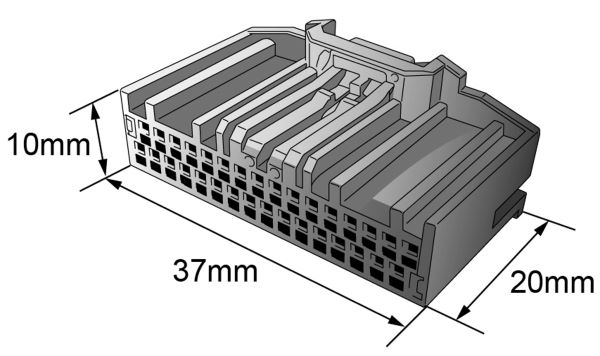

XYRON™ 644Z is used for connectors in automotive battery systems.

Resin materials must be highly reliable to comply with the stringent automotive OEM standards demanded by LV214 and USCAR.

XYRON™ 644Zoffers outstanding flame retardance (UL 94 V-0, 5VA), long-term stability of physical properties (UL746B RTI 125°C), tracking resistance (CTI PLC=2), weather resistance (UL746C f1), and other excellent features.

These superior properties have earned XYRON™ 644Z an extensive track record of use in junction boxes for solar-power generation systems and other similar applications. (Click here to learn more about solar-power generation.)

The same features have also led to XYRON™ 644Z being chosen by a large Chinese battery manufacturer for use in automotive battery connectors.

XYRON™ 500H for the peripheral components of fuel cell stacks. Asahi Kasei recommends

This material features low elution (of ions, oligomers, and other species) and excellent resistance to heat, water, and acid, and their physical properties exhibit minimal degradation upon long-term immersion in liquids.

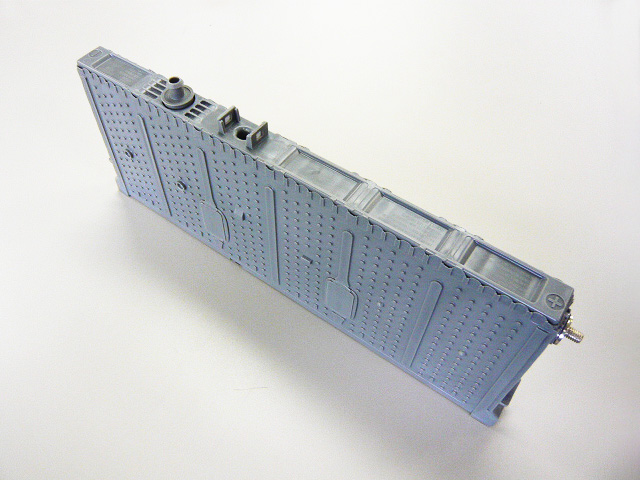

XYRON™ grades for NiMH battery-case components are lower in weight than the metals conventionally used for battery cases, and Asahi Kasei has developed these materials to feature the properties required for battery-cases applications:Flame-retardant

low weight (low specific gravity), alkali resistance, gas-barrier strength, and resistance to metal degradation.

Also, as part of Asahi Kasei’s lineup of ”Contribution through Business Activities” products, these products help to reduce CO2 when in use.

Asahi Kasei’s LEONA™ polyamide resins are engineering plastics featuring excellent strength, rigidity, heat resistance, and chemical resistance.

These materials may be reinforced with fillers such as glass fibers to improve strength, rigidity, durability, and dimensional stability.

For battery end plates—positioned at either end of a battery module to compress and hold in place a stack of battery cells—Asahi Kasei recommends our LEONA™ SN series of resin grades. These materials offer good moldability, feature high strength, high rigidity, good electrical properties (CTI), and good heat resistance.

When insulating protective covers for conducting elements carrying high currents at high voltages must have high strength and long-term stability of physical properties (RTI compliance), Asahi Kasei recommends LEONA™ SN11B, which is well-suited to fabrication of thin-walled components, offers high strength against dielectric breakdown, and features excellent tracking resistance (CTI 600V), flame retardance (UL 94 V-0), and long-term heat resistance (RTI).

Flame-retardant PA66 has expanded its range of applications, primarily in the E&E and automotive domains. Recent years have witnessed growing demands to eliminate materials containing halogens and red phosphorus, both to reduce environmental impact and to improve worker safety.

To support these environmental and worker-safety initiatives, Asahi Kasei embarked on a program to develop new LEONA™ grades using flame retardants without halogens or red phosphorus. This program is now nearing completion.

SunForce™ is Asahi Kasei’s family of XYRON™-based foam materials that combine the unique lightweight and thermal-insulation characteristics of foams with superior properties—far beyond the capabilities of conventional foams—as a result of the use of modified polyphenylene ether (m-PPE) ingredients. These properties include excellent flame retardance (UL-94 V-0), dimensional precision, and suitability for fabricating thin-walled components.

The foamy structure of SunForce™ beads means that this material contains less resin than solid materials—and, as a consequence, fewer pathways for heat to flow through the material, ensuring low thermal conductivity and high thermal insulation.

SunForce™ beads facilitate thermal management for EV batteries.The superior thermal-insulation properties of

The superior thermal-insulation properties of SunForce™ beads facilitate thermal management for EV batteries.

A well-known property of batteries is that their output falls dramatically at low temperatures. To avoid this behavior, various strategies have been devised for electric and high-output hybrid vehicles, involving heaters and other mechanisms, for keeping batteries at sufficiently high temperatures. Asahi Kasei recommends insulating vehicle batteries with SunForce™ beads. This prevents batteries from releasing heat and cooling while the vehicle is at rest, preserving the battery’s high output power for hours with no need for a heater.

When heaters are present, the insulation provided by SunForce™ beads minimizes external thermal loss.

SunForce™beads also reduce the power used to cool batteries while driving by reducing the influx of external heat through the vehicle chassis. This improves heat-exchange efficiency and maximizes battery performance.

SunForce™ materials are lightweight foams with self-extinguishing behavior for fires, and have been adopted or are under consideration for an increasing variety of peripheral components of EV battery packs.

For example, using SunForce™ beads for cell holders in vehicle-mounted battery packs offers the following advantages.

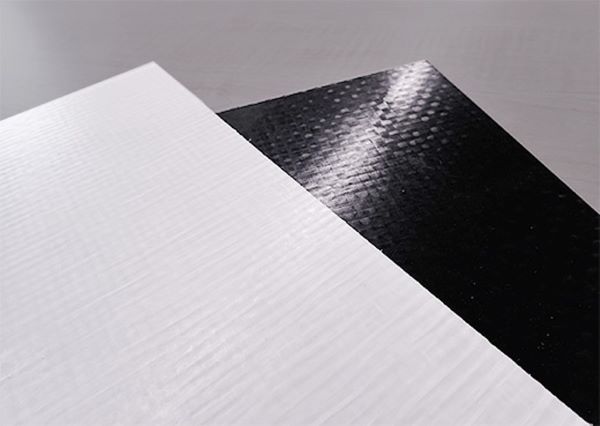

LENCEN™ (c-GFRTP) is a continuous glass fiber reinforced thermoplastic formed by stacking layers of a continuous glass fiber textile with polyamide-66 (PA66) films.

We intend to propose this material as a material which may provide collision safety and weight reduction because it has tensile strength and impact properties equal to or greater than those of metals, and may also contribute to improved reliability and fuel efficiency.

Battery cases in electric vehicles are typically made from metals such as steel or aluminum. The goal of reducing component weight to extend vehicle travel distance suggests the possibility of switching to resin materials, but typical resins cannot offer the required thermal resistance; also, cost reduction is a perennial issue.

LENCEN™(c-GFRTP)

Advantages of

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.